Work In Process (WIP) Tracking

From Raw Material to Finished Product

Work in Process (WIP) tracking refers to tracking each item in production throughout the entire manufacturing process to ensure efficiency, accuracy, and traceability.

In many facilities, WIP tracking is still completed by hand, using spreadsheets and manual data entry; however, automated WIP tracking not only saves times and reduces errors, but it also provides real-time visibility into the flow of materials throughout production.

The foundation for automated WIP tracking is reliable barcode reading. Keep reading to learn about code reading solutions for WIP tracking or contact us to discuss your specific application.

Visibility into Every Step of the Process

Tracking items from raw materials to finished products provides a wide variety of benefits including enabling manufacturers to:

- Know the location and status of customer orders during production to ensure on-time shipment and delivery.

- Track availability of raw materials inventory in real time to facilitate restocking and keep production levels on target.

- Accurately track scrapped or reworked parts to identify areas for process improvement.

- Track finished products back to the original materials for quick and accurate recall of defective products.

These, among other capabilities, enable manufacturers to increase profitability and remain competitive in their industries by increasing efficiency, reducing waste, and allowing for accurate, real-time identification of defects and bottlenecks.

Track Inventory and Origin of Materials

- A product's quality depends on the integrity of its parts, so tracking raw materials is critical.

- Scanning and tracking received goods and raw materials provides manufacturers with valuable data that can be used in case an issue is discovered during quality inspections or product recall.

- If a defect is identified with a particular part on a product, insight into the origin of the defective materials can help manufacturers isolate affected batches and prevent future defects.

- In addition to facilitating quality control and recalls, tracking incoming goods also enables better inventory management to ensure necessary parts are restocked in a timely manner.

Improve Efficiency and Reduce Waste

- Tracking individual components throughout product helps manufacturers improve efficiency, reduce waste, and achieve lean manufacturing goals.

- For example, manufacturers can easily determine which parts are scrapped most often and where the waste is occurring. This allows manufacturers to identify solutions to reduce waste and analyze the success of those solutions over time.

- Scanning components and products at each stage of production also enables manufacturers to track the time between each stage to identify and reduce bottlenecks in production and facilitate staffing and resource allocation.

Ensure Accurate, Timely Order Fulfillment

- Accurate and timely shipments are critical. Missed ship dates, incorrect, or incomplete orders can cause delays throughout the supply chain and decrease customer satisfaction.

- Order, shipping, and tracking information is embedded in separate 1D and 2D barcodes printed every box in a shipment. This information must be verified before the boxes are loaded onto a pallet and the shipment leaves the facility.

- As packages travel at high speeds on the line to the palletizer, an ABR 7000 barcode reader with a liquid lens autofocus verifies each barcode printed on the label.

- Algorithms programmed into the barcode reader locate each barcode, extract the data, and verify that the barcodes match the criteria established during inspection setup.

- This information is then sent over an Ethernet connection to the management system which records the data.

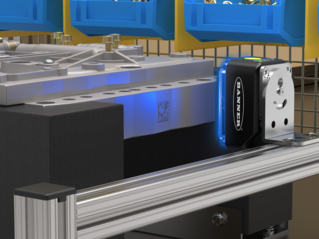

Imager-Based 1D and 2D Barcode Reader

ABR 7000 條碼讀取器提供優異的條碼判讀能力並有多種分辨率和多種鏡頭選項。

- ABR 7000 條碼讀取器提供了進階的功能,包括更遠的讀取距離以及視野、進階的內建光源、不同焦距(包括自動對焦),能夠將多個讀取器連結。

- 強大的判讀能力可以判讀最困難的 1D 和 2D 條碼,包括 DPM 以及對比度不佳的條碼

- 能夠透過機載按鈕或是連結至 PC,使用 Barcode Manager、Banner 的免費軟體進行快速組態

- 內建的 LED 指示燈以及方便調整的焦距設定,提供更大的彈性以解決更多的產品應用。

- 多樣的鏡頭選擇,包括軟體可調的自動對焦,可以針對不同的讀取距離作出調整。

- 工廠通訊選項(包括乙太網路和序列)可以在製造車間中集成。

- 嵌入式的 Web 伺服器介面,可以透過網路監控讀取的圖像或統計資料。

Imager-Based 1D and 2D Barcode Reader

iVu BCR 系列條碼讀取器結合了強大的解碼功能和易用性,以解決具有挑戰性的可追溯性應用。這些多功能條碼讀取器有一系列鏡頭、照明和使用者介面選項。

- 能夠讀取廣泛的 1D 和 2D 條碼,包括損壞、失真和其他難以讀取的條碼。

- 能夠在一次檢測中從各個方向同時讀取多個條碼

- 使用集成式觸摸屏、遠端觸摸屏或 PC 介面設定、管理和監控檢測。

- 以太網路和序列通訊協議簡化了設備集成,實現了 IIoT 資料收集

- 堅固的 IP67 級外殼是狹小空間和工業環境的理想選擇

- 眾多的集成照明選項簡化了安裝,優化了對比度。

- 可互換鏡頭,包括各種標準和 C 型安裝選項,可滿足任何應用的需求。

TCNM Series

Laser-Based 1D Barcode Scanner

TCNM感測器能夠讀取十幾種常用的一維條碼符號,可提供快速讀取速率、寬景深和高解析度。

- 讀取十幾種常見的一維條碼符號

- 每秒完成500到1,000次掃描

- 使用SMART-TEACH按鈕和LED指示燈完成基本設定和診斷操作

- 條碼重建算法將多個掃描組合,以重建損壞的條碼資訊

- GeniusPlus軟件和專有的感測器內通訊協議消除了在多感測器設定中對外部多工器的需求

- 堅固的 IP65 外殼