Direct Part Mark (DPM) Code Reading

Extremely Challenging Codes

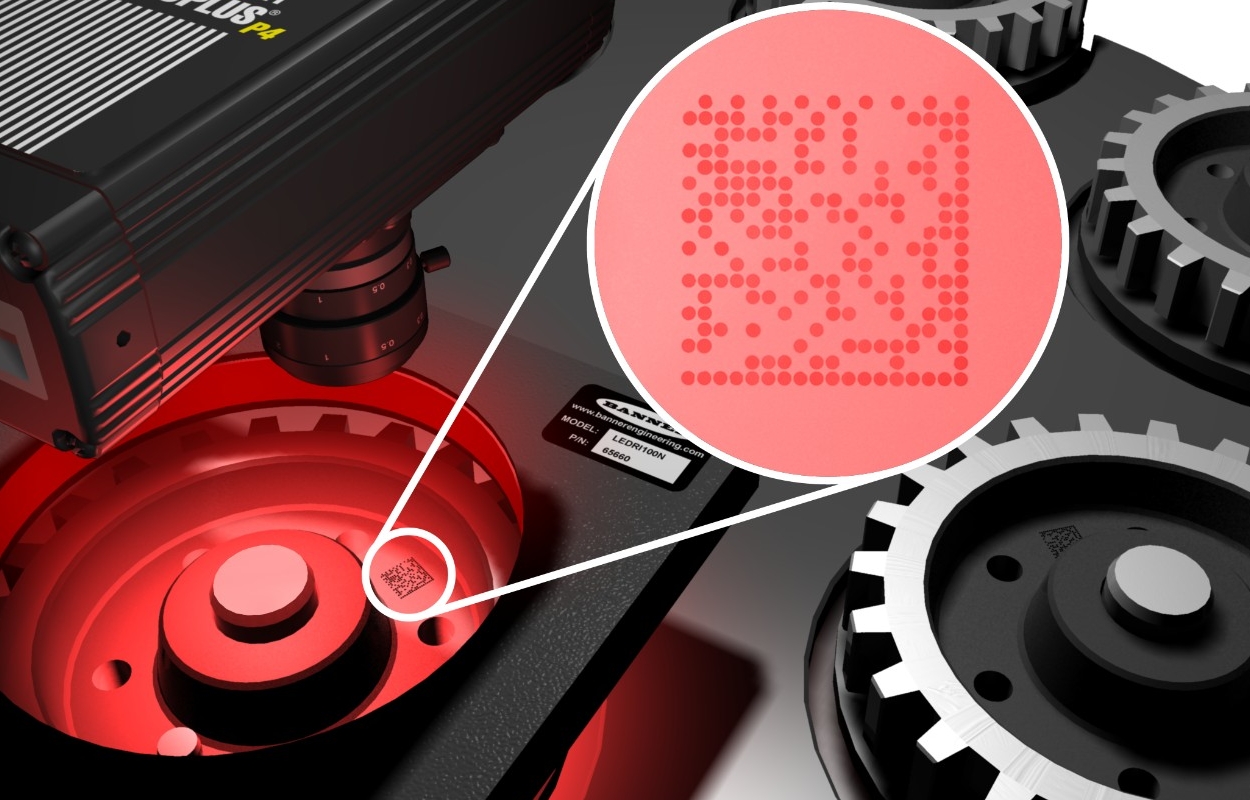

Direct Part Marks (DPM) are codes, symbols, and text that are etched or printed directly onto the surface of a part instead of affixed by a label. DPM codes, which are most commonly Data Matrix or QR codes, are used for track and trace purposes in a variety of industries, particularly automotive and electronics manufacturing.

The benefit of DPM codes is that they are permanent and cannot be easily removed, obscured, or damaged. DPM codes are also a popular choice for parts with textured surfaces (label will not stick) and very small parts (label will not fit). Because DPM codes last as long as the part itself, the piece can be identified easily identified throughout its entire lifecycle, also known as "cradle-to-grave" traceability.

However, DPM codes can be extremely challenging to read due to poor contrast, so finding a DPM code reading solution is essential for reliable identification.

Since they are etched directly onto the part, DPM codes are very low contrast compared to traditional black barcodes printed on a white background. Plus, there can be significant variability in DPM codes, where and how they are printed on a surface, and features of the surface itself that can significantly impact code readability.

For example, many DPM codes are etched onto reflective, curved, or uneven surface which can be very challenging for barcode readers to identify reliably.

Also, the surface is rarely uniform, meaning that it may also contain granules, stripes, streaks, or other irregularities and imperfections that can further interfere with reliable code reading.

Advanced imager-based code readers use special DPM code reading algorithms to solve these applications reliably. Besides, low angle lighting or the use of different color LEDs can be used to create additional contrast and improve code visibility.

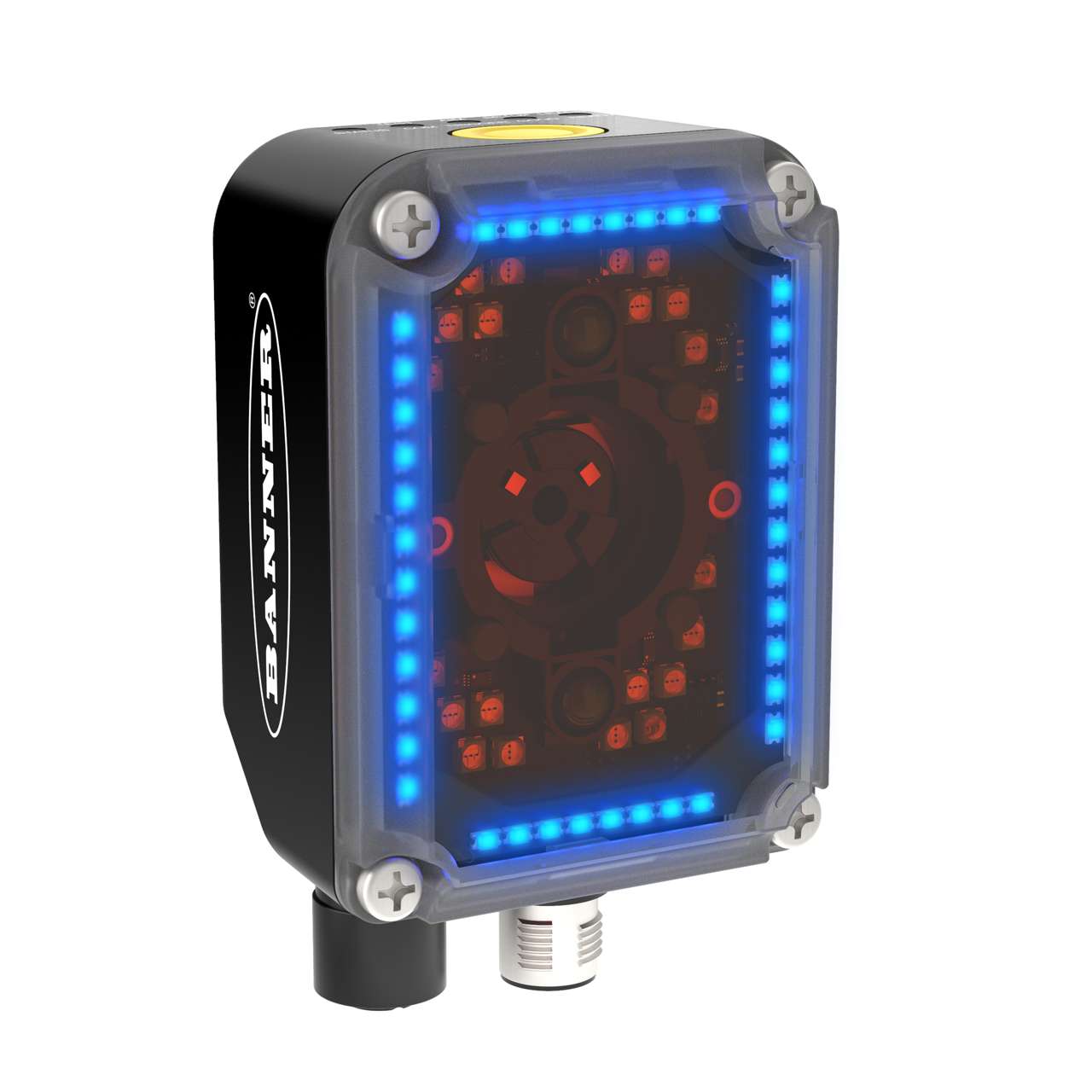

Imager-Based Code Reader with Multicolor LEDs

- In automotive manufacturing, to ensure that vehicle components can be traced throughout their entire life cycle, Data Matrix and other 2D codes are permanently etched into the surface of each component.

- A barcode reader with dark-field illumination like the ABR 7000 is ideal for applications where the DPM code has been etched onto a reflective surface. Dark-field illumination utilizes blue LED lights built into the barcode reader to make the code appear much darker than the surrounding area.

- The enhanced contrast between the code and the surface of the component allows the barcode reader to capture a detailed image of the inspection area with every aspect of the Data Matrix code well defined.

- The information contained in the code is then verified and sent over an Ethernet connection to the factory management system which logs the data for traceability.

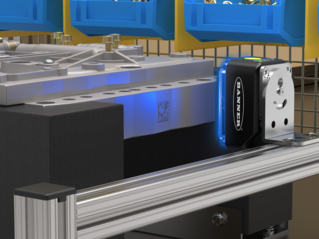

Reliable Code Reading in Confined Spaces

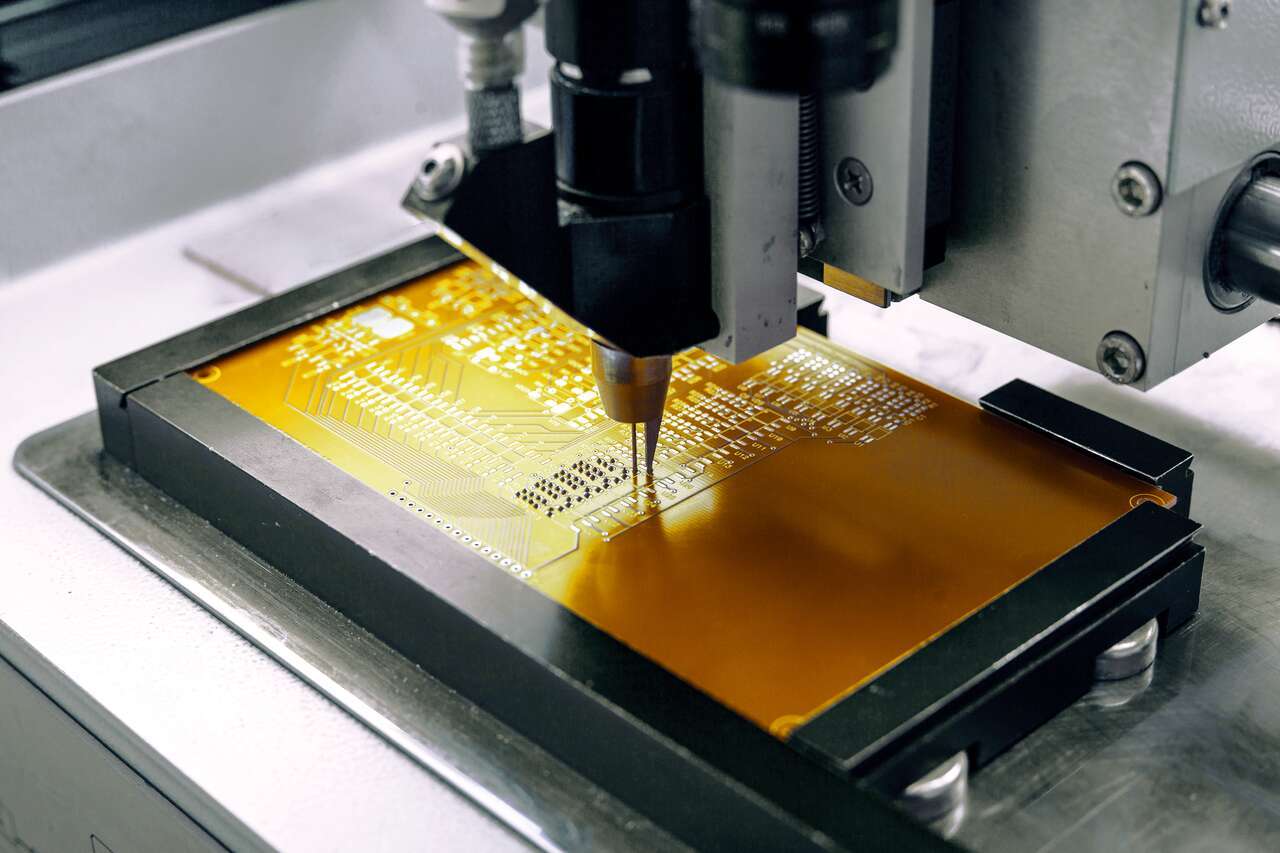

- DPM codes are also standard in electronics manufacturing.

- These codes are especially challenging because, in addition to being low contrast, the codes are also tiny, as they are printed directly onto electronic components.

- Also, there is often limited space to mount a code-reading device.

- A compact barcode reader, like the ABR 3000, is perfect for tight spaces common in the electronics industry.

- The imager-based code reader uses unique algorithms to reliably identify small, low contrast DPM codes and can send data via Ethernet to PLC controls for traceability.

Imager-Based Barcode Readers from Banner

Need to read other challenging codes besides DPM codes? Imager-based barcode readers reliably read 1D and 2D barcodes in any orientation.

Banner Engineering offers code reading solutions that can reliably decode difficult-to-read, low quality, and damaged codes—as well as codes printed on highly reflective surfaces.

Watch the video to learn more about what's new, or browse our selection of imager-based code reading products.

Imager-Based Barcode Reader

ABR 7000 條碼讀取器提供優異的條碼判讀能力並有多種分辨率和多種鏡頭選項。

- ABR 7000 條碼讀取器提供了進階的功能,包括更遠的讀取距離以及視野、進階的內建光源、不同焦距(包括自動對焦),能夠將多個讀取器連結。

- 強大的判讀能力可以判讀最困難的 1D 和 2D 條碼,包括 DPM 以及對比度不佳的條碼

- 能夠透過機載按鈕或是連結至 PC,使用 Barcode Manager、Banner 的免費軟體進行快速組態

- 內建的 LED 指示燈以及方便調整的焦距設定,提供更大的彈性以解決更多的產品應用。

- 多樣的鏡頭選擇,包括軟體可調的自動對焦,可以針對不同的讀取距離作出調整。

- 工廠通訊選項(包括乙太網路和序列)可以在製造車間中集成。

- 嵌入式的 Web 伺服器介面,可以透過網路監控讀取的圖像或統計資料。

Compact Imager-Based Barcode Reader

ABR 3000 條碼讀取器提供優異的條碼判讀能力並有緊湊型規格、多種分辨率和多種鏡頭選項。

- 強大的判讀能力可以判讀最困難的 1D 和 2D 條碼

- ABR 3000 是狹窄區域以及近距離讀取應用的理想選擇

- 精巧的金屬外殼適用於工業環境

- 能夠透過機載按鈕或是連結至 PC,使用 Barcode Manager、Banner 的免費軟體進行快速組態

- 內建的 LED 指示燈以及方便調整的焦距設定,提供更大的彈性以解決更多的產品應用。

- 工廠通訊選項(包括乙太網路、序列或 USB)可以在製造車間中集成。

- 嵌入式的 Web 伺服器介面,可以透過網路監控讀取的圖像或統計資料。

iVu BCR Series

Imager-Based Barcode Reader

iVu BCR 系列條碼讀取器結合了強大的解碼功能和易用性,以解決具有挑戰性的可追溯性應用。這些多功能條碼讀取器有一系列鏡頭、照明和使用者介面選項。

- 能夠讀取廣泛的 1D 和 2D 條碼,包括損壞、失真和其他難以讀取的條碼。

- 能夠在一次檢測中從各個方向同時讀取多個條碼

- 使用集成式觸摸屏、遠端觸摸屏或 PC 介面設定、管理和監控檢測。

- 以太網路和序列通訊協議簡化了設備集成,實現了 IIoT 資料收集

- 堅固的 IP67 級外殼是狹小空間和工業環境的理想選擇

- 眾多的集成照明選項簡化了安裝,優化了對比度。

- 可互換鏡頭,包括各種標準和 C 型安裝選項,可滿足任何應用的需求。