Multicolored Targets and Product Changeover

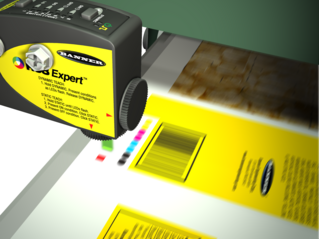

Multicolored targets are increasingly becoming the norm, especially in consumer packaged goods industries. The various types of packaging used include shiny, glossy, or other unpredictable surfaces.

For example, reflective, multicolored, and wrinkled material such as foil or film is frequently used in food and beverage packaging and can cause inconsistent sensor readings.

Multicolored targets are challenging for many sensors to consistently detect. This is because some colors, such as very dark colors, are more difficult for traditional photoelectric sensors to see because darker colors reflect back less light back to the sensor compared to lighter colors. Multicolored targets also have frequent color transitions and varying amounts of reflectivity that further impact sensing reliability.

Product changeover creates additional challenges because sensors must be able to reliably detect a variety of color combinations. To keep up with consumer demand, manufacturers require flexible sensing solutions that can detect all colors and that can be quickly updated with each new "recipe" during product changeover to keep production lines moving.

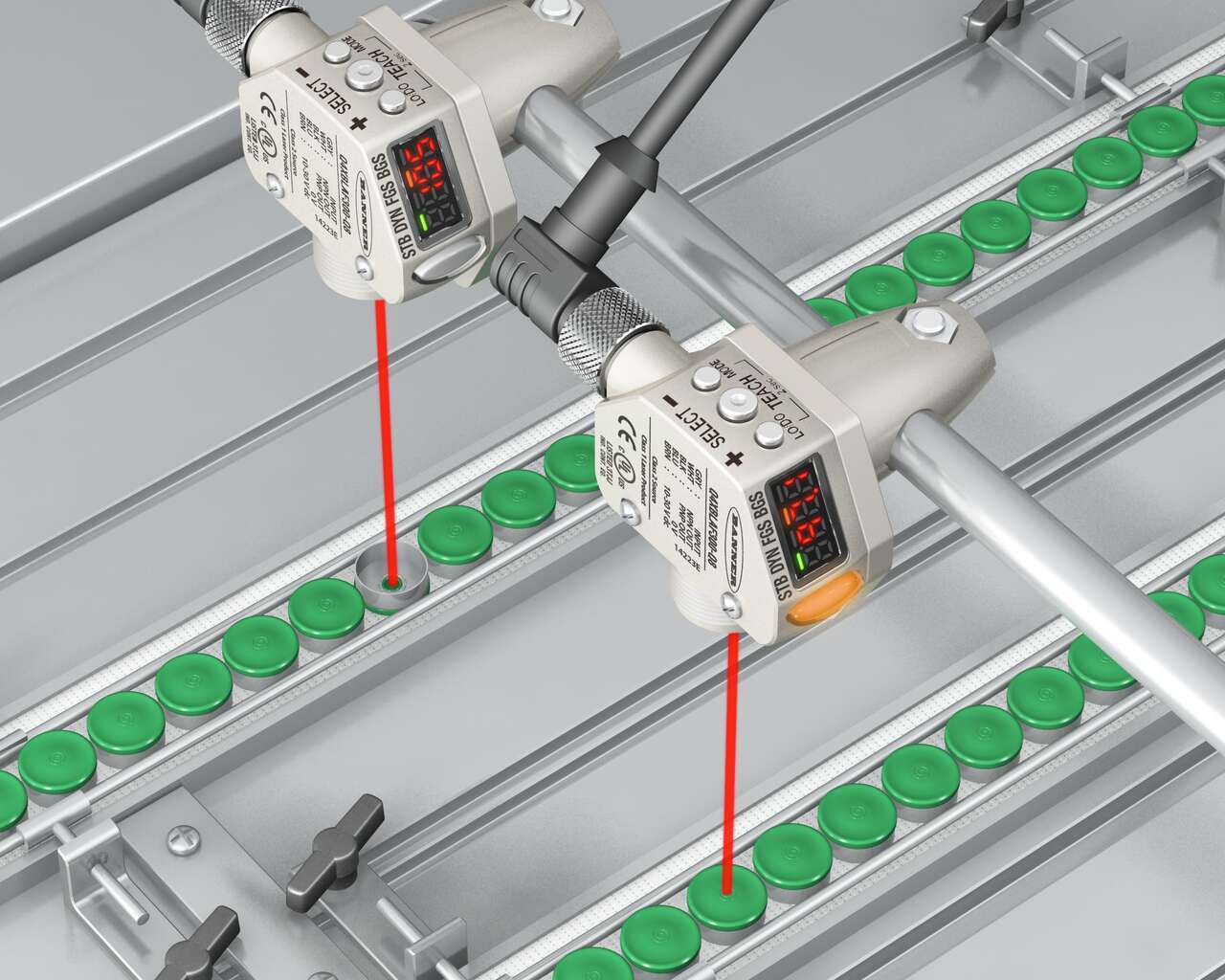

Laser distance sensors are an excellent choice for detecting multicolored packaging because cause they determine target presence or absence using distance. Laser distance sensors are unaffected by color transitions, and they can reliably detect all different varieties of packaging, regardless of color or reflectivity.

In addition, many laser distance sensors from Banner Engineering feature exceptionally high excess gain to reliably detect very dark colors, as well as automatic gain adjustment to dynamically increase or decrease sensing power depending on target reflectivity.

With IO-Link, users can easily read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources.

In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

Manufacturers use many terms to describe sensor performance, but not all manufacturers use the same specifications, which can make it challenging to compare different models of sensors. Read the article to learn tips for choosing the right sensor for any application.

Laser Distance Sensor with IO-Link, 9.5 cm to 2 m

Q5X 雷射背景消除式感測器是一款功能強大,專為解決問題而生的感測器 ,有著兼具經濟性及工業標準的矩形外殼。

- 量測範圍 從 9.5 cm (4 英吋) 到 2 m (6 呎 6 吋)

- 出色的高增益值表現讓 Q5X 可以穩定的偵測深色的物體 (反射度低於 6% 的黑色目標)

- 可以穩定的在黑色背景的情況下偵測黑色的目標物,高反射度的金屬背景下穩定偵測黑色目標物,透明及高反光度的物體,彩色的包裝,以及各種顏色的目標物

- 雙教導模式可以同時量測距離值以及反射光強度,能夠解決各種應用難題