Track and Trace for Product Recall

Mitigate Damages with Accurate, Timely Recalls

An important goal for any manufacturer is to avoid product recall. Recalls are costly, in terms of both actual costs of repair, replacement, or buy-backs as well as the cost of a tarnished brand reputation.

Implementing quality control solutions can help reduce the risk of product defects and safety hazards; however, even the most effective quality control does not eliminate all risk.

Recalls happen, and when they do, it is critical that manufacturers are prepared to respond quickly by identifying affected products and issuing a timely recall to mitigate damages.

When recalls occur, a manufacturer's response can make or break its reputation, and by extension, impact customer loyalty and future profits.

Manufacturers must act quickly and recall all affected products that have already been purchased. In some cases, manufacturers must be able to quickly pull affected inventory from their own shelves, distribution centers, and retail establishments. In other instances, like in many automotive recalls, consumers may need their purchases repaired in a timely manner. Furthermore, to prevent unnecessary costs, manufacturers must avoid inadvertently recalling unaffected products.

Track and trace solutions help manufacturers execute recalls quickly and accurately, so that affected products can be repaired or removed from the market, and the issue can be resolved quickly.

These solutions depend on reliable identification of individual products throughout the supply chain—most commonly by scanning barcodes at every stage from production to purchase. Track and trace solutions are only as reliable as the devices that scan the codes, so selecting the appropriate identification technology is critical.

Track and Trace for Food Safety

- In food packaging, barcodes are embedded with information specific to each product and production run in order to identify products throughout the supply chain.

- As part of a track and trace program, a packing house verifies product barcodes at multiple points during packaging, creating a record that will allow the company to quickly identify and isolate any product with quality issues in the event of a recall.

- Imager-based barcode readers, like the ABR 3000 from Banner, are capable of decoding the widest range of 1D and 2D barcodes. Deployed along the packaging line, the ABR 3000 verifies that the barcode printed on each package is present, readable, and correct for each production run.

- The information contained in the barcodes is sent via an Ethernet connection to the company’s production management system which records the data for future referrence.

Track and Trace for Automotive Components

- Many automotive suppliers are incorporating Ultra Violet (UV) barcodes for component traceability and quality control.

- The technology uses UV-based ink that is only visible to the human eye when illuminated with a UV light source. Suppliers can store key informationin a small code printed directly on the component, without affecting design or aesthetics.

- In the event of a recall, codes can be scanned to verify that components were installed and tested in compliance with standards.

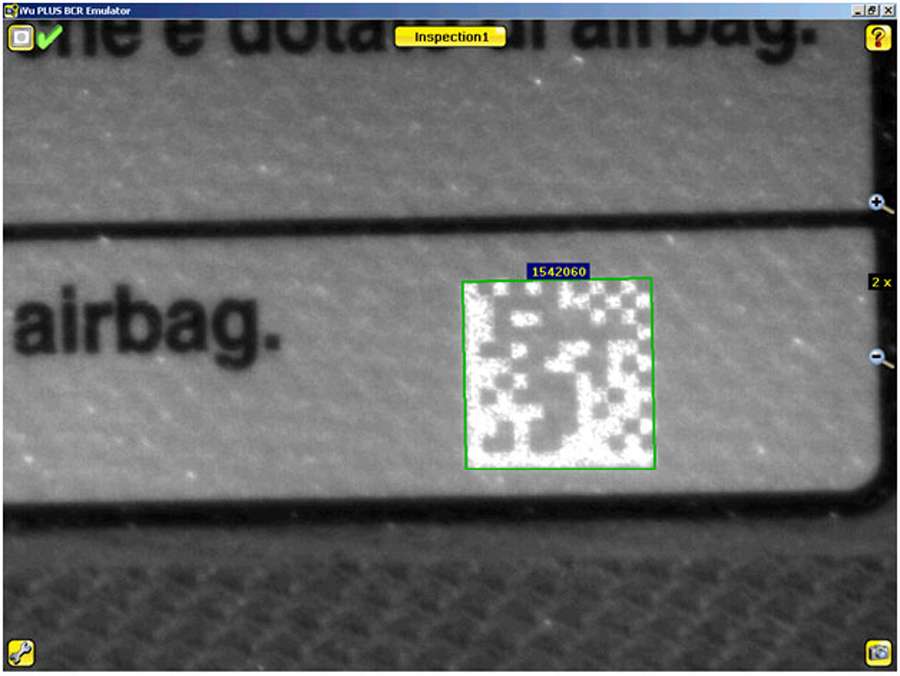

- In this application, an iVu BCR barcode reader with a C-mount lens, UV spotlight, and Ethernet capabilities can be used to read invisible 2D Data Matrix codes and send data via EtherNet/IP to a PLC for error proofing and traceability.

Track and Trace for Pharmaceutical Packaging

- Traceability is only effective for facilitating recalls if the correct codes are attached to the correct products. Therefore, validating codes prior to shipment is critical.

- In the pharmaceutical industry, medical supplies are often individually packaged in sealed pouches.

- Before product can be shipped, the barcodes must be validated to ensure that the correct barcode is affixed to the correct product for accurate traceability.

- An imager-based barcode reader validates each barcode and sends data via Ethernet IP to a PLC for future reference in case of recalls.

Imager-Based 1D and 2D Barcode Reader

ABR 系列條碼讀取器提供優異的條碼判讀能力,以解決最具挑戰性的跟踪和追溯應用。提供兩種緊湊型規格、多種照明組態、多種分辨率和多種鏡頭選擇。

- 能夠讀取完整的 1D 和 2D 條碼庫

- 提供兩種緊湊型規格,防護等級高達 IP67,適用於工業環境

- 分辨率高達 2 MP,提供多種照明組態和鏡頭焦距(包括自動對焦),適用於任何應用場合

- 適用於困難應用的型號,包括 DPM 代碼讀取和極化窗口

- 能夠使用機載按鈕或具有全功能 Barcode Manager 的 PC 在幾分鐘內進行組態

- 多樣的鏡頭選擇,包括軟體可調的自動對焦,可簡化設定和組態

- 透過工業以太網路、序列和 USB 進行組態以簡化設備集成並啟用 IIoT 資料收集

- Web 介面用於在任何網路上遠端監控、組態和查看統計資料

Imager-Based 1D and 2D Barcode Reader

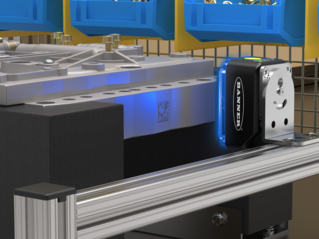

iVu BCR 系列條碼讀取器結合了強大的解碼功能和易用性,以解決具有挑戰性的可追溯性應用。這些多功能條碼讀取器有一系列鏡頭、照明和使用者介面選項。

- 能夠讀取廣泛的 1D 和 2D 條碼,包括損壞、失真和其他難以讀取的條碼。

- 能夠在一次檢測中從各個方向同時讀取多個條碼

- 使用集成式觸摸屏、遠端觸摸屏或 PC 介面設定、管理和監控檢測。

- 以太網路和序列通訊協議簡化了設備集成,實現了 IIoT 資料收集

- 堅固的 IP67 級外殼是狹小空間和工業環境的理想選擇

- 眾多的集成照明選項簡化了安裝,優化了對比度。

- 可互換鏡頭,包括各種標準和 C 型安裝選項,可滿足任何應用的需求。

TCNM Series

Laser-Based 1D Barcode Scanner

TCNM感測器能夠讀取十幾種常用的一維條碼符號,可提供快速讀取速率、寬景深和高解析度。

- 讀取十幾種常見的一維條碼符號

- 每秒完成500到1,000次掃描

- 使用SMART-TEACH按鈕和LED指示燈完成基本設定和診斷操作

- 條碼重建算法將多個掃描組合,以重建損壞的條碼資訊

- GeniusPlus軟件和專有的感測器內通訊協議消除了在多感測器設定中對外部多工器的需求

- 堅固的 IP65 外殼