Stocking and Replenishment

Keep Shelves and Stations Stocked and Organized

Picking activities are only effective if the correct parts or inventory are put in the right place and ready to be picked. Because of this, an efficient stocking and replenishment solution is a necessity in many industries.

Warehouses and distribution facilities require an efficient method for putting inventory on the shelves so that orders will be easily accessible during fulfillment. In manufacturing facilities, assembly and kitting stations must be replenished with parts before they run out.

Put-to-light solutions improve the efficiency and accuracy of stocking and replenishment activities and can help prevent downtime by reducing delays due to misplaced or incorrect parts.

Stocking and replenishment are critical because misplaced items, incorrect parts, and delays in restocking shelves or workstations can significantly impact productivity downstream.

Proper stocking and replenishment is also essential for error-proofing and quality control. For example, if assembly stations are stocked with incorrect parts, the quality of the assembly may be compromised, and assemblers may not be able to meet production goals. In material handling, misplaced inventory can lead to order delays or mix-ups.

Light-guided putting solutions reduce the risk of errors and help ensure that work areas are properly stocked at all times.

Stocked Workstations Mean No Waiting for Items

- Put-to-light solutions speed up stocking and replenishment times by clearly and visually guiding workers to the correct location for each item.

- Faster replenishment means assemblers and production staff spend less time waiting for more parts and can maintain an appropriate pace to meet production goals.

- Efficient stocking also enables faster and more accurate order fulfillment at warehouses and distribution facilities.

Get the Right Items in the Right Location

- By facilitating proper stocking and replenishment, put-to-light solutions help ensure the quality of the final product.

- In manufacturing facilities, keeping assembly stations stocked with the correct parts reduces the risk of errors down the line.

- For example, a put-to-light solution uses light to guide a worker to place the proper size screws in the correct bins so the assembler will pick the right size screw to fasten other parts together securely.

Reduce Recalls & Ensure Customer Satisfaction

- Because put-to-light solutions improve efficiency and reduce errors, they ultimately help save costs and maximize profits.

- Fewer errors mean a lower risk of a product recall due to manufacturing defects.

- Speed and accuracy increase customer satisfaction and confidence, leading to repeat business and higher profits.

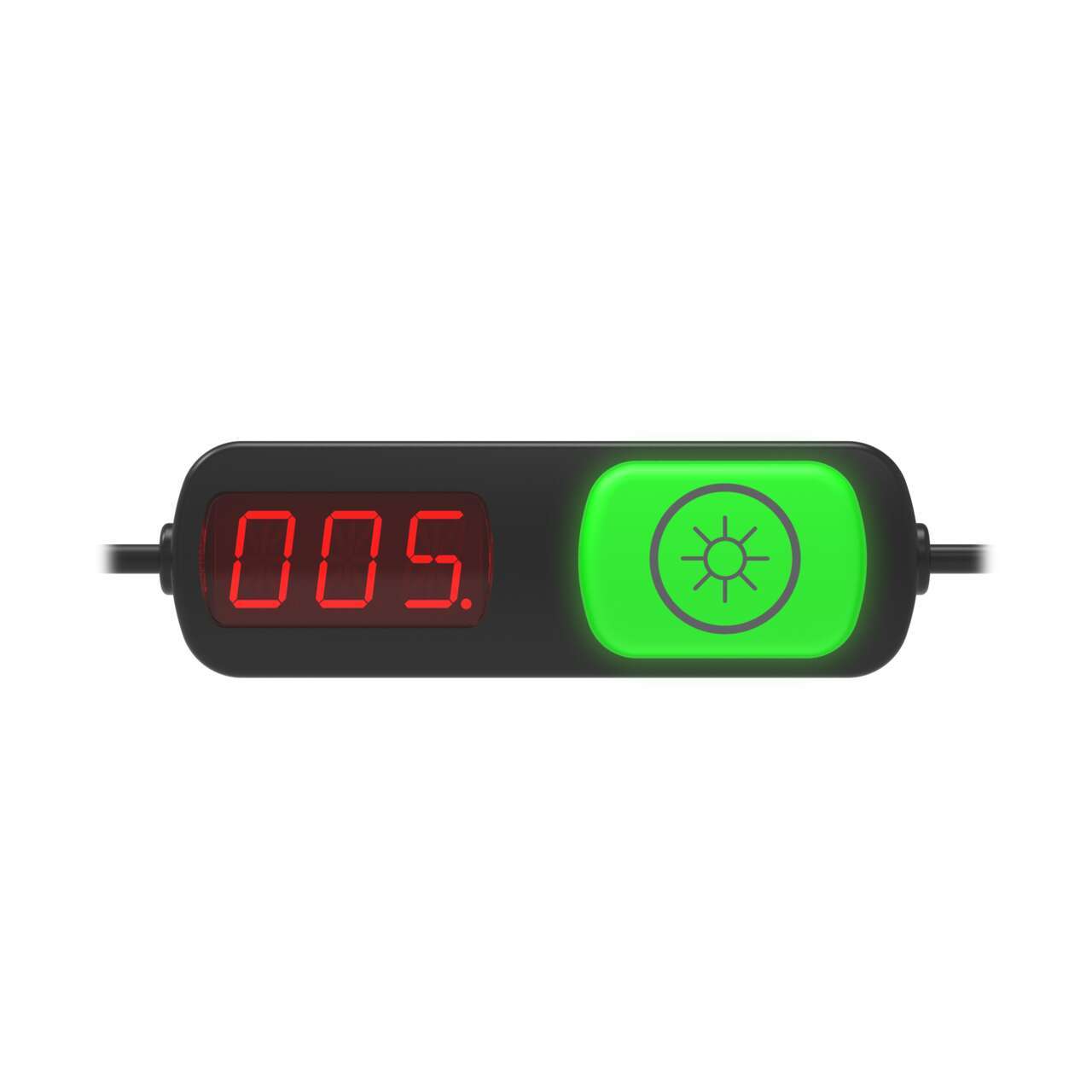

Versatile, Scalable Pick-to-Light Devices

PTL110 多功能拾取指示燈,提供觸控按鈕,光學式感測器, 以及三位數的顯示螢幕,將多個裝置串接後可以建構一個功能強大的拾取指示系統。 具備反應快速以及多種安裝選項的特性,PTL110 系列提供了拾取料件,組裝以及相關的應用一個快速,高生產力,以及高品質的解決方案。

- 提供光學式以及觸控按鈕觸發的型號。

- 部分型號 具備三位數的顯示螢幕,可以顯示計數的數量或提供其他的指示。

- M12 快速接頭可以快速安全的將多個裝置安裝起來,無須額外的線材。

- 指示燈提供 14 色以及多種動畫模式,可以區分不同的狀況。

- 透過 PICK-IQ™功能,實用的Modbus 序列通訊,使用 Common ID 可以減少多裝置輪詢所造成的延遲。

- 可以搭配DXM700 無線控制器,應用在購物車或是移動取料設備上。

Pick to Light Devices

Pick to Light Devices

S22觸控系列是多功能系列產品,結合一組明亮的指示燈,透過簡單的觸控來觸發固態開關功能。是先進製造和零件拾取作業的理想選擇。

- 結合了觸控功能的明亮指示燈,輕觸即可觸發開關訊號。

- 使用 Banner 新推出的Pro Editor 設定軟體,搭配 Pro 設定線來設定不同的燈色、閃爍及動畫模式

- 堅固耐用、符合成本效益且易於安裝的多色指示燈,附帶觸控按鈕功能

- 固態的電子結構,確保超長使用壽命以及減少維修上的需求

- IP69K 防水結構,可用於沖洗環境

- 22 mm 螺紋聚碳酸酯安裝底座

- 符合人體工學的設計可以有效減輕手部,手腕,以及手臂的負擔

- 無論是空手或是戴著手套,都能觸發按鈕