Traceability in Pharmaceutical Supply Chain

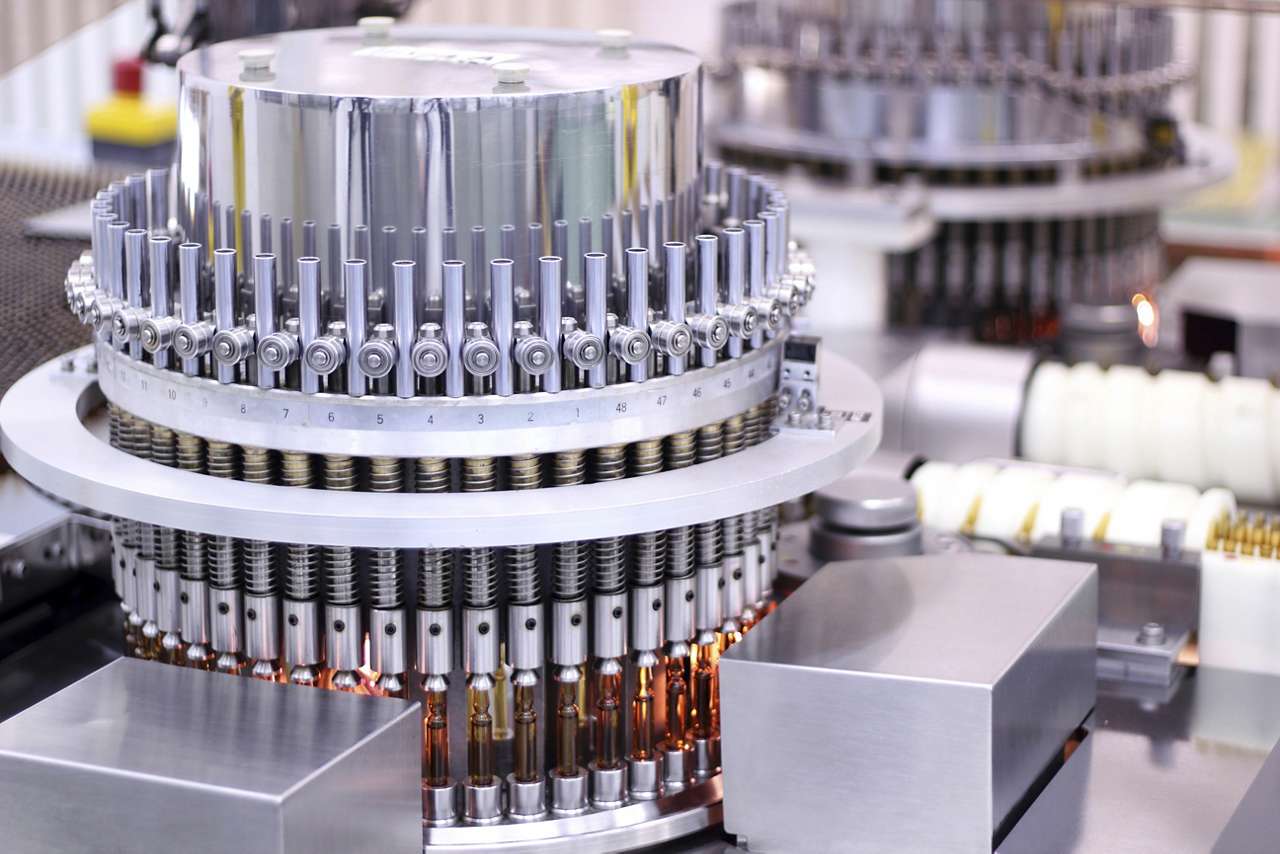

Ensure Safety and Compliance with Regulations

Pharmaceutical traceability is required to eliminate counterfeits, ensure patient safety, and comply with regulations.

According to GS1, the global traceability standard for healthcare, "Traceability in healthcare enables you to see the movement of prescription drugs or medical devices across the supply chain. You can trace back to identify the history of the transfers and locations of a product, from the point of manufacture onwards. And you can track forwards to see the intended route of the product towards to the point of care."

Know the What, When, Where, and Why

In the healthcare industry, counterfeit or defective product can have significant consequences on patient health. Because of this, pharmaceutical manufacturers must adhere to strict regulations to ensure that their products can always be traced back to their source and that the Chain of Custody (CoC) and Chain of Ownership (CoO) for products are reliably documented. In addition, manufacturers must be able to quickly and completely recall any defective products to ensure patient safety.

To accomplish these goals, a reliable barcode reading solution must be implemented at every stage of the process. Barcode readers capture valuable data which can be used, when needed, to determine four dimensions of traceability outlined by GS1:

- What products are impacted?

- When did this time-stamped event occur?

- Where was the product. Where is it now?

- Why was this observed, which process step?

Ensure Product Quality and Complete Accuracy

- In the pharmaceutical industry, barcodes are often printed with clear ink that can be challenging to detect on labels due to minimal contrast.

- It is vital that each label has a barcode to ensure the highest quality product and complete accuracy.

- An iVu BCR barcode reader with ultraviolet (UV) ring light is an ideal solution for detecting bar codes in a low contrast situation.

- The iVu is coupled with UV illumination for an all-in-one solution that improves contrast on clear labels, so barcodes are easily and accurately detected for reliable traceability.

Verify Correct Product and Documentation

- Once the product itself has been verified for accuracy and quality, medicine bottles must be packaged into the appropriate boxes.

- Also, box inserts (that include user instructions and warnings) need to be verified and identified before sealing the package to ensure accurate documentation is delivered to the customer.

- To quickly and efficiently perform this inspection, the data matrix code on the documentation is read and verified before the final packaging process.

- The iVu BCR barcode reader verifies that the Data Matrix code on the insert matches the product on the packaging line. In doing so, the barcode reader also gathers valuable data that can be used to identify and isolate any issues that may arise.

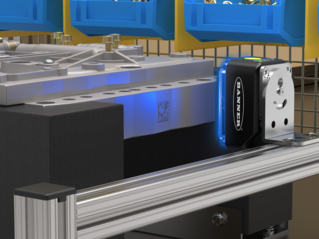

Reliable Code Reading in Tight Spaces

- Another common challenge in the pharmaceutical industry is that products, such as pill bottles and vials, are quite small.

- Because of this, the codes affixed to the products are often small, wrapped around a curved surface, and challenging to read.

- In addition, there is often limited space to mount a code-reading device.

- The ABR 3000 compact barcode readers from Banner reliably read difficult codes in tight spaces and reach GS1 standards for the pharmaceutical industry.

Compact Imager-Based Barcode Reader

ABR 3000 條碼讀取器提供優異的條碼判讀能力並有緊湊型規格、多種分辨率和多種鏡頭選項。

- 強大的判讀能力可以判讀最困難的 1D 和 2D 條碼

- ABR 3000 是狹窄區域以及近距離讀取應用的理想選擇

- 精巧的金屬外殼適用於工業環境

- 能夠透過機載按鈕或是連結至 PC,使用 Barcode Manager、Banner 的免費軟體進行快速組態

- 內建的 LED 指示燈以及方便調整的焦距設定,提供更大的彈性以解決更多的產品應用。

- 工廠通訊選項(包括乙太網路、序列或 USB)可以在製造車間中集成。

- 嵌入式的 Web 伺服器介面,可以透過網路監控讀取的圖像或統計資料。

Imager-Based Barcode Reader

iVu BCR 系列條碼讀取器結合了強大的解碼功能和易用性,以解決具有挑戰性的可追溯性應用。這些多功能條碼讀取器有一系列鏡頭、照明和使用者介面選項。

- 能夠讀取廣泛的 1D 和 2D 條碼,包括損壞、失真和其他難以讀取的條碼。

- 能夠在一次檢測中從各個方向同時讀取多個條碼

- 使用集成式觸摸屏、遠端觸摸屏或 PC 介面設定、管理和監控檢測。

- 以太網路和序列通訊協議簡化了設備集成,實現了 IIoT 資料收集

- 堅固的 IP67 級外殼是狹小空間和工業環境的理想選擇

- 眾多的集成照明選項簡化了安裝,優化了對比度。

- 可互換鏡頭,包括各種標準和 C 型安裝選項,可滿足任何應用的需求。

ABR 7000

Powerful Imager-Based Barcode Reader

ABR 7000 條碼讀取器提供優異的條碼判讀能力並有多種分辨率和多種鏡頭選項。

- ABR 7000 條碼讀取器提供了進階的功能,包括更遠的讀取距離以及視野、進階的內建光源、不同焦距(包括自動對焦),能夠將多個讀取器連結。

- 強大的判讀能力可以判讀最困難的 1D 和 2D 條碼,包括 DPM 以及對比度不佳的條碼

- 能夠透過機載按鈕或是連結至 PC,使用 Barcode Manager、Banner 的免費軟體進行快速組態

- 內建的 LED 指示燈以及方便調整的焦距設定,提供更大的彈性以解決更多的產品應用。

- 多樣的鏡頭選擇,包括軟體可調的自動對焦,可以針對不同的讀取距離作出調整。

- 工廠通訊選項(包括乙太網路和序列)可以在製造車間中集成。

- 嵌入式的 Web 伺服器介面,可以透過網路監控讀取的圖像或統計資料。