Smart, Scalable Safety Control

The Safety Controller is the Backbone of Your Safety System

Safety control is a critical and a required part of any safety system. It ensures that your safety measures 1) do not fail, or 2) if failure is inevitable, fail in a predictably safe way.

A safety controller is often an ideal safety control solution, because it provides more functionality than a safety relay, at a lower cost than a safety PLC. In addition, a smart, scalable safety controller can expand with your needs as well as enable remote monitoring of your machine safety systems.

Designing a Smart Machine Safety System That Expands With Your Business

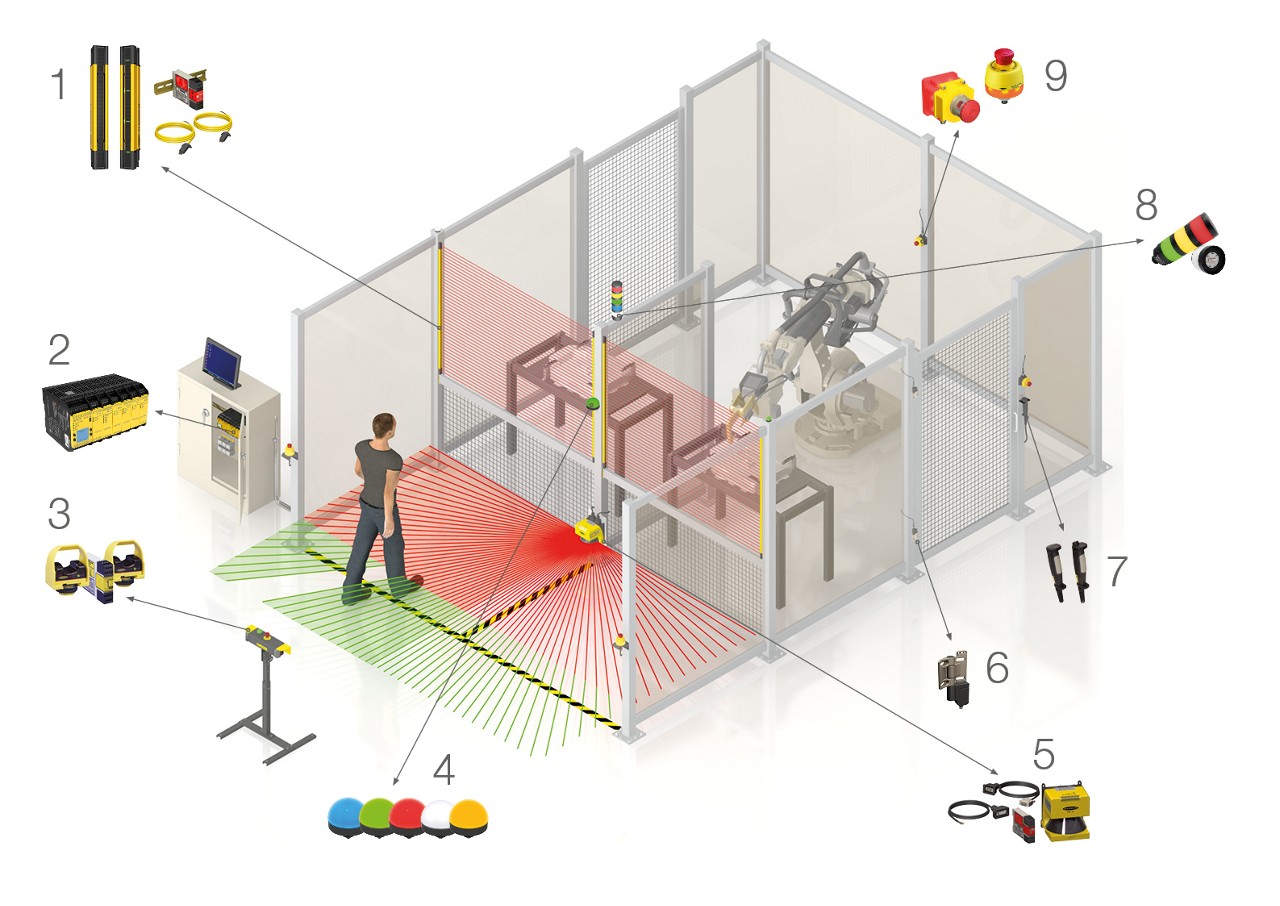

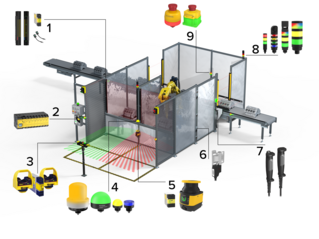

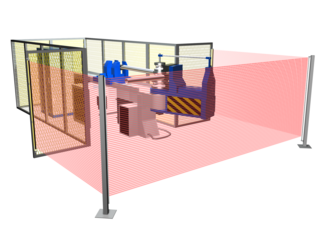

There are many different types of safety devices that all work together to protect workers from injury and protect machines from damage. A safety system can quickly become complex and daunting, with many areas to protect and many devices to implement and manage.

However, an easy-to-use and flexible safety controller will make it much easier to get your system up and running quickly with minimal downtime and will allow you to easily expand and adapt to future needs. Note that for simple applications, a full-feature safety controller may not be necessary. In these cases, a safety relay provides reliable safety control with minimal complexity.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application prior to implementing any machine safety measures.

Guards Multiple Points and Expands to Meet Changing Requirements

Safeguarding multiple points across a large machines and assembly lines can be challenging because of the variety of hazards present. With multiple zones and dozens of safety devices, wiring with traditional relay modules can become complicated. The result is high costs and long installation times to create the appropriate safety logic and circuits.

An expanable safety controller provides a simpler solution to safeguard hazards, protect personnel, and scale to meet the needs a very complex safety applications. Also, a safety controller that can expand when you need it allows for the required agility to meet deadlines and implement changes quickly.

Saves time and costs with minimal learning curve

Intuitive programming saves time and costs. An icon-based, drag-and-drop user interface reduces the learning curve and speeds up commissioning, and it makes it easy to quickly modify and update the configuration when changes are needed. Note that many safety controllers have password protection to ensure only authorized users can make changes, reducing the risk of operators bypassing the system.

Furthermore, look for a safety controller interface that automatically generates wiring diagrams to speed up installation. In addition, a controller with live simulation will allow users to test configurations and changes quickly before implementation.

Monitor Safety Devices Remotely

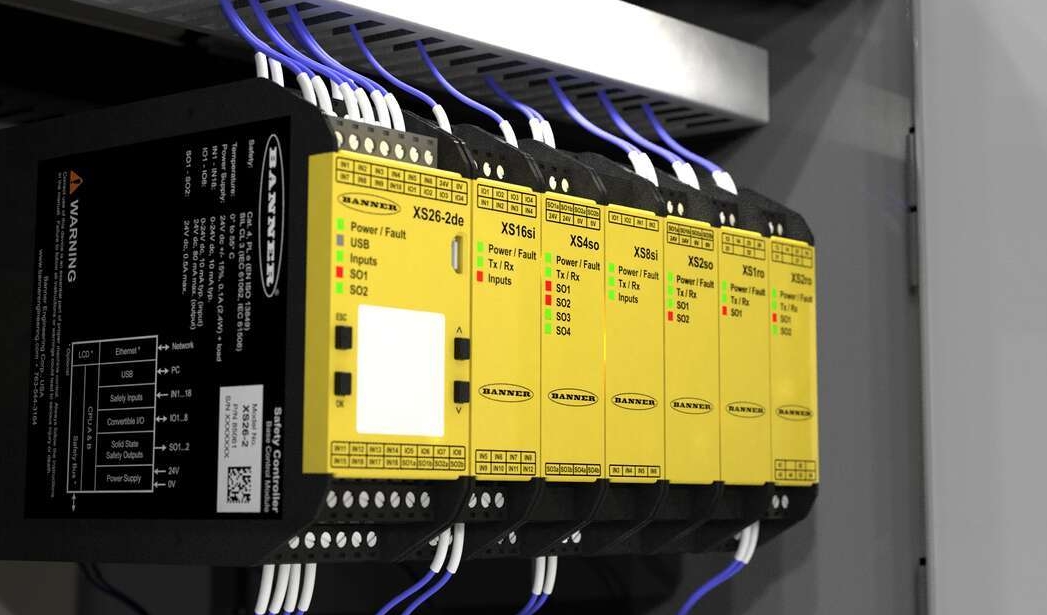

Real time fault monitoring allows quick identification of problems. Look for a safety controller that can communicate with your PLC via Profinet, Modbus, TCP/IP, PCCC, etc. This allows you to remotely monitor your safety devices and will ensure that you are notified in real time when there is an issue with the safety system. Also, with configurable IO, inputs can be changed to non-safe outputs to control indicatior lights for local notification of a fault.

For example, XS26 and SC26 safety controllers can communicate up to 256 virtual status updates to a PLC or HMI that can be stored and tracked for future analysis. Furthermore, these controllers can also receive up to 80 virtual non-safety inputs to remotely turn safety devices or indicators on and off, enable mute functions, cancel off-delays, initiate a reset, and accomplish other tasks quickly and easily in the HMI without complicated programming.

Safety Controllers

SC26-2 體積小,具有布林邏輯計算功能,易於使用、具備靈活彈性和高效能的特性於一身。

- 可監測各種輸入裝置,如 E-Stop 按鈕、拉繩開關、寸動開關、保護性安全停止裝置、互鎖防護裝置或閘門、光學感測器、雙手控制裝置和安全地墊

- 提供彈性的布林邏輯計算程式供使用者編輯

- 直覺式的編輯環境,可以快速的導入安全系統

- 預先配置各項安全功能區塊,包括雙手控制裝置、遮蔽功能和寸動開關,可以簡化應用設定的複雜度

- 控制器可將 26 個輸入點中的其中 8 個點位設定為輸出接點使用,讓產品使用上更加彈性

![Introduction to XS26-2/SC26-2 Functional View - Part 1 [Video]](/content/dam/banner-engineering/video/video-thumbnails/new_video_thumbnails/XS26-2_Video_Thumbnail.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplifying Safety Feature Management [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)