3 Solutions for Semiconductor Wafer Presence Detection

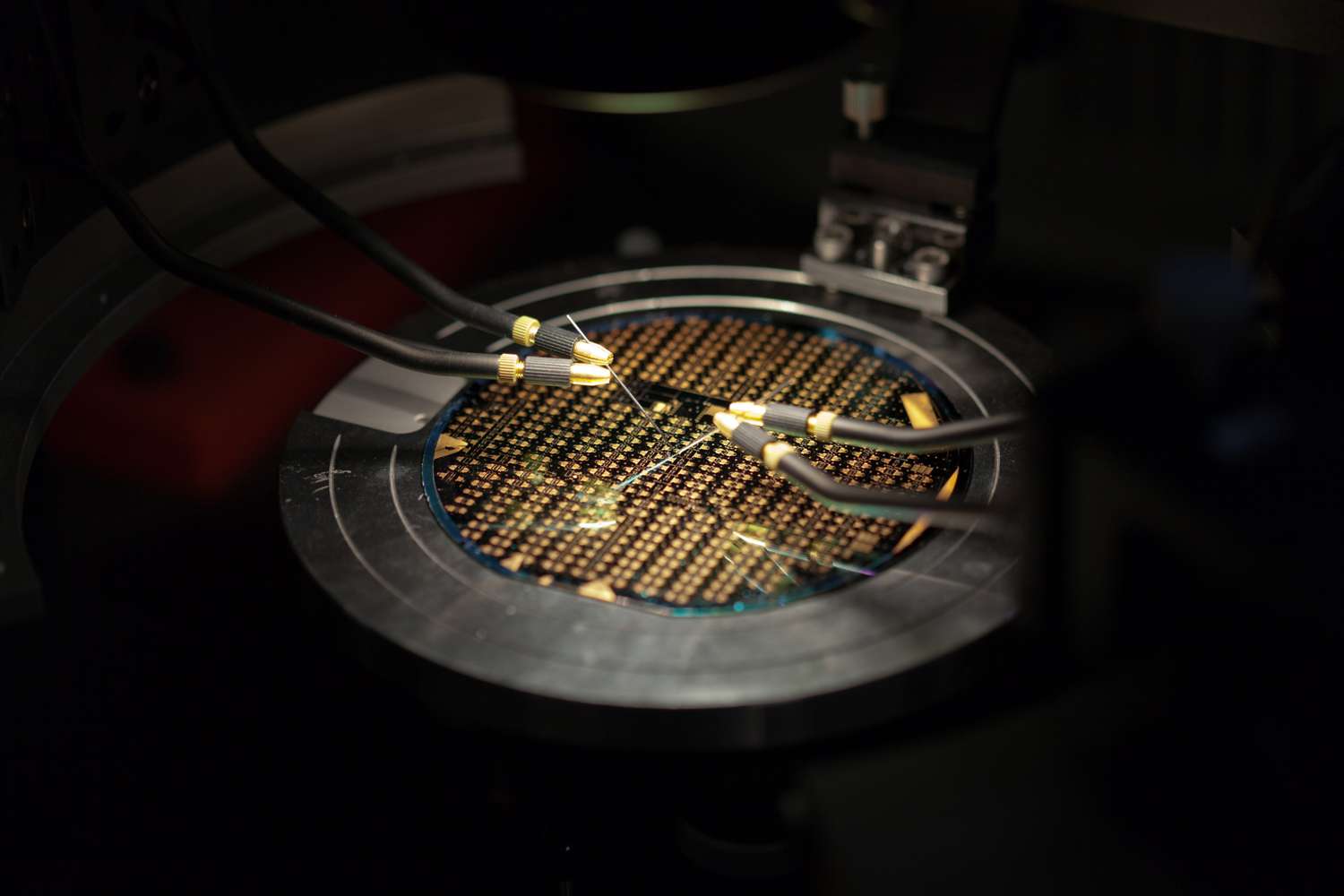

Semiconductor wafers can be transparent or reflective, both of which can be challenging for sensors to detect. Because of this, it is important to use a technology that can detect both types of wafers reliably. Sensor mounting can also be a challenge when detecting wafers in a vacuum chamber.

Fortunately, Banner Engineering offers several solutions that can be used to reliably detect both clear and reflective wafers in a vacuum chamber. This article describes 3 technologies that can be used to solve this application.

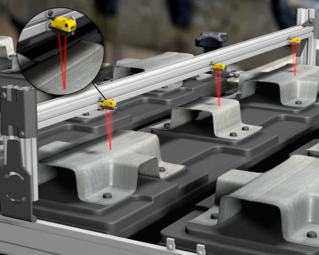

1. Dual Mode Laser Distance Sensor Through Window Glass

The first type of sensor that can be used to detect wafers is a dual mode laser distance sensor mounted through a window glass. Laser sensors with dual mode capability like the Q4X from Banner detect not only changes in distance but also changes in light intensity from a stable background condition. This allows the Q4X to detect challenging targets such as clear and reflective wafers with a high level of accuracy.

A laser distance sensor with dual mode can detect not only when the target is present within a certain distance, but also when it returns a certain amount of light to the receiver. For this to work, a stable reference surface must be taught, and the distance and intensity of the reference surface are recorded and used as a baseline.

The presence of a transparent or reflective wafer entering the sensing range of the beam alters the perceived distance and light intensity from the background condition. The Q4X from Banner is also able to detect through a glass window without interference.

2. Photoelectric Sensor Through Window Glass

Another sensor that accurately detects challenging wafers targets is a retro-reflective photoelectric sensor with a coaxial optical design. The QS18 with Clear Object Detection emits and receive light along a single narrow axis. This optimizes the detection of transparent wafers by dramatically reducing the risk of false detection from reflected light.

Additionally, because light emitted and received travels on a single narrow beam, these sensors can see through a small aperture, allowing them to be used through a glass window for vacuum chamber applications. Photoelectric sensors with polarizing filters will emit and detect light waves of a specific polarization, ignoring all other light waves. This further reduces the risk of false detection caused by reflected light.

Learn more about polarized coaxial optics for detecting transparent objects.

3. Vacuum Chamber-Rated Fiber

Finally, a fiber optic solution that is rated for use in a vacuum chamber can also be used to detect transparent or reflective wafers.

With a fiber optic solution, the fiber amplifier is mounted outside of the vacuum chamber. A special pass-through fitting with a vacuum-rated glass fiber mounted inside brings fiber optic light into the chamber.

The fiber is the positioned so that the light shines towards a vacuum-rated glass reflector, detecting both glass and reflective wafers that pass between the fiber and the reflector.

For More Information

Featured Products

Related Articles

如何使用紅外光的光電感測器進行水溶液偵測

了解Banner的QS30 H2O光電感測器如何以獨特的光學特性可靠地偵測水分子的有無。

冷光感測器:常見問題解答

冷光感測器會發出人眼看不到的紫外光,使目標物材料發出可見光譜中的光。本文提供有關冷光感測器的常見問題的答案。

How to Choose the Best Sensor for Clear Object Detection

了解在透明物件偵測應用中的常見感測器類型之間的差異,例如超音波感測器與光電反射板式感測器。

What is Excess Gain and How to Use It To Choose a Sensor

本文會闡述什麼是過量增益,要如何測量,以及一般工業的感測應用中需要使用多少過量增益值的感測器通則。