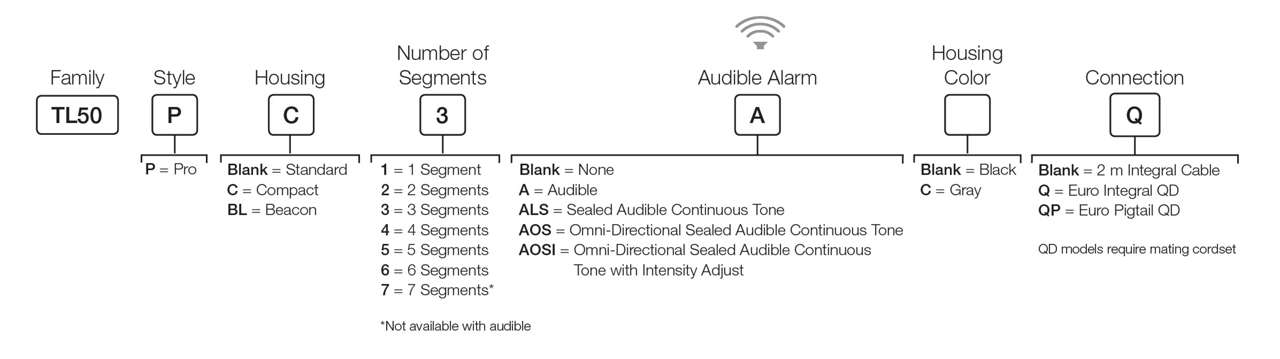

Advanced Functionality without Requiring IO-Link

With the free Pro Editor software, users can easily customize the TL50 Pro tower light with a wide variety of predefined color and animation options without requiring IO-Link. Pro Editor models are discretely controlled and ideal for users who do not have IO-Link, but who want more control and customization than a standard indicator.

Simplify Your Supply Chain

Programmable RGB indicators make supply chains more efficient by allowing users to standardize on fewer models of TL50 Pro tower lights that can be customized as needed. Standardizing on a few models of customizable tower lights saves inventory costs and eliminates lengthy lead times for new configurations.

Give Your Machines a Voice

From classic segment control to advanced status indication, TL50 Pro tower lights enable a wide range of possibilities. The variety of colors and animations add nuance to the visual language of your machines and provide more insight at a glance.

In addition to providing traditional status information with each segment, the whole TL50 Pro tower light can be used to indicate the following dynamic statuses:

The TL50 Pro series tower light has a fixed internal timer as a visual aid to help operators keep track of production cycle time.

Takt Time Indication

Timer mode visually displays a countdown and provides assemblers with feedback on takt time remaining to keep production goals on target. For example, a 5 segment TL50 Pro might start out with all segments lit green at the beginning of the process. As the time elapses, fewer and fewer segments are lit, and the color changes from green to yellow. With 20% time remaining, only the bottom segment remains lit and can change from yellow to red to warn assemblers that time is running out to complete the task.

Part Counting

Counter mode can be used to track part count on a production line. Similar to timer mode which displays time remaining, the TL50 Pro in counter mode can display the percentage of parts completed to track progress on production goals.

Transitional States

A 50/50 rotate animation on the entire length of the tower light can be used to indicate transitional machine states such as startup, changeover, warmup, and material loading. Operators can easily identify the state of the machine and spend transition times on other productive activities versus just waiting.

Material Level Indication

Using either PWM (pulse width modulation) or PFM (pulse frequency modulation) mode, the TL50 Pro can be used to provide highly visible indication of critical level statuses that can be seen from a distance. Staff can quickly diagnose whether level of material is too high or too low at a glance and are immediately prepared to respond to the situation.