食品包裝紙箱組裝解決方案

一旦托盤經過密封並通過所有檢查,就需要裝進正確的盒子中。紙箱機採用壓平的食品包裝盒,然後加以組裝,並將食物密封在其中以利儲存和銷售。

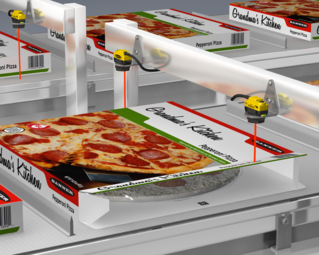

當托盤放入每個紙箱內時,箱口蓋就會密封,然後紙箱就繼續進入下一個包裝階段。箱口蓋的偵測、紙箱堆疊高度和條碼讀取是這類型機器上最常見的應用。

條碼辨識是確保食品裝進正確紙箱的一種方法。這個過程非常重要,因為如果紙箱標籤不正確,未標示出可能的過敏原,就可能要召回產品。

快速準確的讀取條碼可防止生產線減速和堆積堵塞。箱口蓋和膠水的偵測確保箱口蓋上有膠水,以便妥善密封。不正確的封箱也可能導致產品召回和浪費。

食品業會出現更換產品生產線的情況,而包裝上就會有不同的圖形或顏色。多功能感測器可以穩定的提供感測不同類型的包裝,而不需要冗時的停機時間來更換產品線。Banner Engineering 針對不同的包裝,提供了各種不同的解決方案,可以穩定偵測不同顏色、表面以及材質的目標物,包含雷射感測器Q4X系列,特別針對難以偵測的包裝材質所設計,例如高反光面的鋁箔,或是色彩斑斕的不平整表面,皆能提供穩定偵測功能。

特色應用

Leading Edge Detection of Packages with a Thin, Flexible Edge

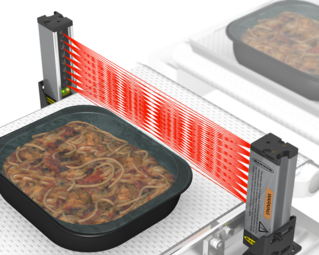

Banner’s LX Series is an economical solution for detecting the leading edge of flat objects, such as the frozen dinner containers. With a web of modulated light, the LX Series part-sensing light screen can detect any item—in any position—passing through the light screen.

紙箱堆疊高度

產品經常性的更換,與減少安裝時間

Carton Trigger For Date/Lot Code Printing

With a narrow beam that projects a small bright spot, the QS18LLP laser, polarized, retro-reflective sensors provide precise position control when triggering various devices. In this application, the QS18LLP is able to correctly detect the glossy carton as it travels down the conveyor—without proxing—and trigger the ink jet printer to print the date/lot code on the carton. The second sensor triggers the P4 OMNI to inspect the date/lot code and verify it is legible and correct.

包裝式冷凍食品的封口檢測

QS18LD雷射直反式感測器掃描包裝頂部,以確定是否有封口打開。雷射直反式感測器提供精確的偵測,以驗證冷凍包裝是否被正確密封。

Illuminating Inside A Cartoner

Banner’s WLS28 LED Light Strips allow operators to identify frozen dinners that have not properly entered a carton and fix the problem with minimal downtime. Their long-lasting and durable cool white light means they’re an energy-efficient solution for illuminating the inside of a cartoner. IP69K rated, they can handle frequent machine wash down procedures.