Wireless Vibration Monitoring and Predictive Maintenance Solutions

Monitor machine health utilizing predictive maintenance by continuously monitoring for vibration and temperature changes.

Create point to multi point networks that distribute I/O over large areas. Input and output types include discrete (dry contact, PNP/NPN, float), analog (0 to 10 V dc, 0 to 20 mA), temperature (thermocouple, thermistor and RTD), AC/DC relay (SPDT) and asynchronous counter (up to 10kHz).

Performance Series Industrial Wireless Gateways and Nodes

Applications

A large cabinet maker needs to monitor and control the temperature and humidity throughout many rooms in a large production facility. Manual environmental readings of the entire plant were conducted periodically throughout the week. These manual readings only provided a snapshot of information and gathering the data took more than three hours. The customer did not have real-time, accurate information that could be used to control the plant environment. Manually collecting this information and controlling the fan system was timeconsuming and resulted in errors that damaged wood in storage, work in progress, and finished cabinets.

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered SureCross Node and a Banner T-GAGE temperature sensor. When using host control systems, the SureCross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

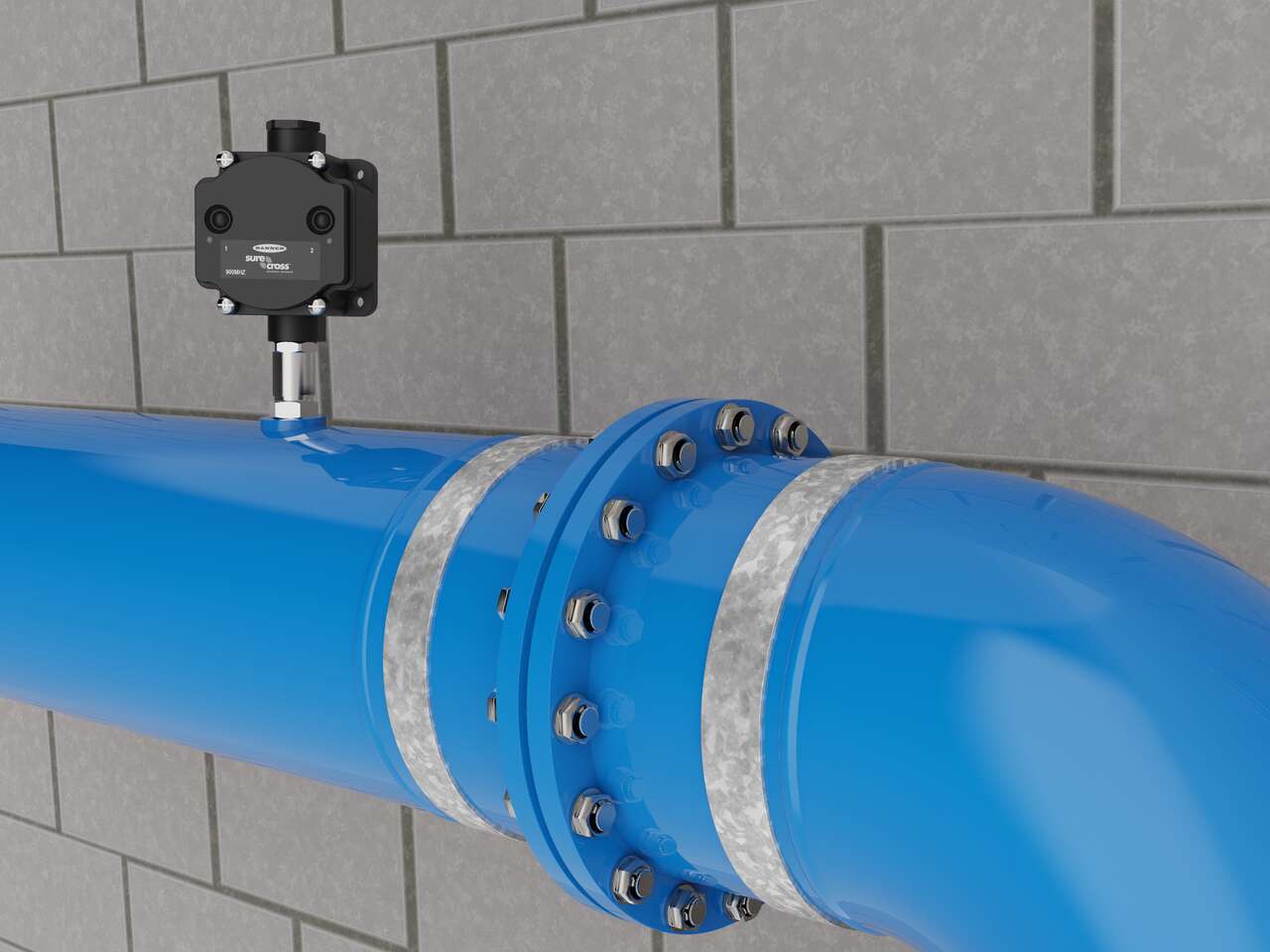

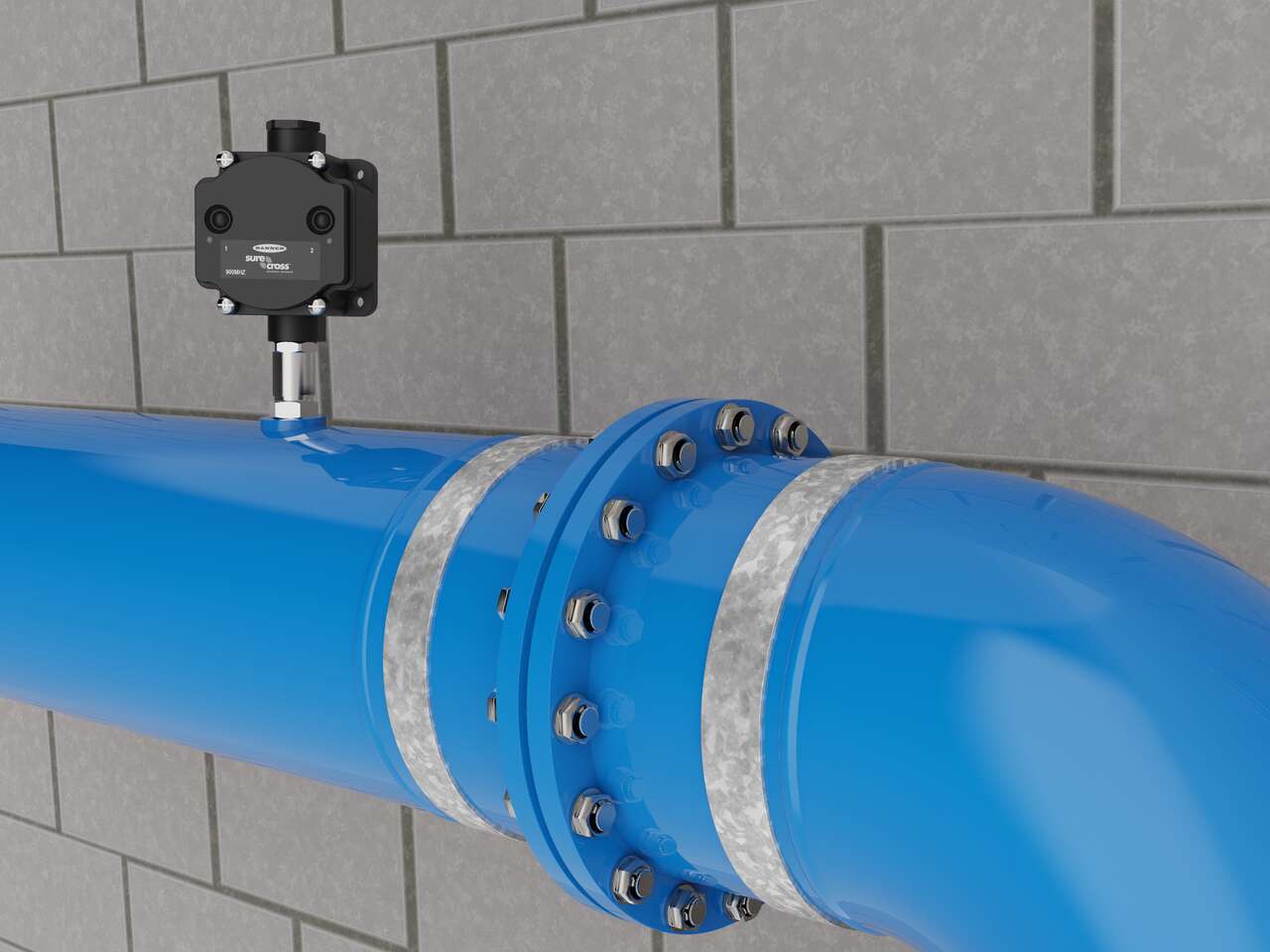

Performance Series all-in-one wireless pressure sensors make it easy to monitor pressure levels in large and complex systems from any network-enabled location.

A Banner wireless solution is a simple way to optimize inventory, reduce errors, and minimize waste. Each SureCross Performance Node with I/O Mapping can be equipped with up to six EZ-LIGHT operator indicator lights. The SureCross Gateway is conveniently located at a central location where maintenance personnel and management can monitor the parts consumption throughout the site.

![Thermal Remediation Temperature Measurement [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

The EPA has placed restrictions on the use of many fumigants citing a correlation between their use and ozone depletion. As an alternative, a large-scale flour mill performs three to four thermal remediations per year to eradicate flour beetles. The temperature inside the mill is brought up to 122° F (50° C). This is done gradually to minimize equipment and building strain caused by heat expansion.

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

A large cabinet maker needs to monitor and control the temperature and humidity throughout many rooms in a large production facility. Manual environmental readings of the entire plant were conducted periodically throughout the week. These manual readings only provided a snapshot of information and gathering the data took more than three hours. The customer did not have real-time, accurate information that could be used to control the plant environment. Manually collecting this information and controlling the fan system was timeconsuming and resulted in errors that damaged wood in storage, work in progress, and finished cabinets.

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered SureCross Node and a Banner T-GAGE temperature sensor. When using host control systems, the SureCross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

Performance Series all-in-one wireless pressure sensors make it easy to monitor pressure levels in large and complex systems from any network-enabled location.

A Banner wireless solution is a simple way to optimize inventory, reduce errors, and minimize waste. Each SureCross Performance Node with I/O Mapping can be equipped with up to six EZ-LIGHT operator indicator lights. The SureCross Gateway is conveniently located at a central location where maintenance personnel and management can monitor the parts consumption throughout the site.

![Thermal Remediation Temperature Measurement [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

The EPA has placed restrictions on the use of many fumigants citing a correlation between their use and ozone depletion. As an alternative, a large-scale flour mill performs three to four thermal remediations per year to eradicate flour beetles. The temperature inside the mill is brought up to 122° F (50° C). This is done gradually to minimize equipment and building strain caused by heat expansion.

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.