Increase Productivity and Quality in a Snap

Make your legacy injection molding machine smart: Give it Industry 4.0 capability with SNAP SIGNAL

It’s time you know when your injection molding machine is running low on pellets. And it’s time you’re aware of your dryer’s environmental parameters.

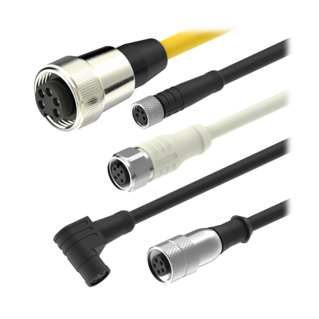

To manage your process better and improve productivity, SNAP SIGNAL products interface with existing level sensors and temperature/humidity probes. The products use analog-to-Modbus converters, splitters, cordsets, and an edge gateway to complete the solution. If you need to add sensors to the equipment, Banner has you covered.

- Locally indicate hopper levels with Banner’s PRO LED lighting

- Easily push hopper level and curing data to the cloud with Banner’s edge gateway

- Develop insights, and visualize data on the floor or at any location with web dashboards, available from Banner Cloud Data Services

Start Simply and Fast

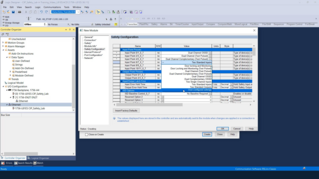

Model |

Description |

T30UXUC |

Ultrasonic Sensor |

M12FTH |

Temperature & Humidity Sensor |

S15C-TBD |

Converter |

DXM1200 |

Controller/Gateway |

WLS15P |

Smart Level Indicator Light |

Splitter Cable |

|

T Splitter |

|

DEE2R-53D |

Quick Connect Cable (double-ended) |

MQDC-506 |

Quick Connect Cable (single-ended) |