機械手臂工作區的安全防護

A robotic case packer can pose multiple risks for accident or injury. Hard guarding protects personnel from machine hazards by preventing contact with the case packer but is excessive in applications where access is necessary to operate equipment and complete tasks. Read on to learn how an SX5-B safety laser scanner protects personnel and allows easy access to equipment.

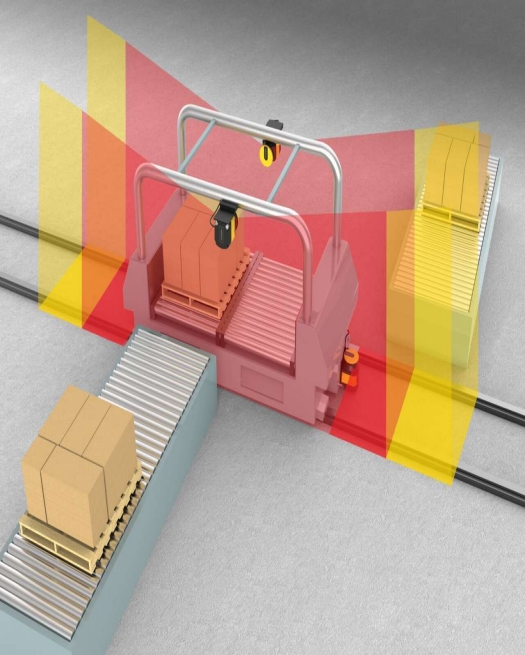

A robotic case packer picks up completed products from an infeed conveyor and places them in a box on a separate conveyor. This motion is repeated hundreds of times an hour. Any person coming into contact with the robot while it is in operation would be at risk of serious injury from this motion.

Hard guarding surrounds the case packer, protecting personnel from potential hazards by impeding access to the case packer. However, the operator work station must remain free of these barriers in order to allow staff to inspect shipments and service equipment. Safety mats are often used to safeguard access points such as this, but in busy work environments, these can wear out quickly and must be replaced frequently, increasing expenses and machine downtime.

Banner’s SX5-B safety laser scanner is ideal for applications like this where worker safety is absolutely essential and access to equipment is crucial to processes and machine operation. This versatile safety device protects personnel by continuously scanning a user-defined area of up to 275° to create a two-dimensional protected zone that must be crossed to reach the hazard.

The SX5-B uses Banner's powerful safety laser scanner software which features menu-driven tools that simplify device setup and speed deployment. The intuitive user interface makes it easy to design and update safety and warning zones to accommodate area infrastructure and meet specific safety requirements.

Installed approximately 30 cm from the floor at the base of the operator work station, the SX5-B continuously scans the area surrounding the work station. Any person or object entering the warning zone will be detected by the SX5-B. This will trigger a WLS27 multicolor LED strip light to fill the area with bright yellow light to warn the individual that they have entered a protected area. If the warning is ignored and the safety zone is breached, the motion of the robot will come to a controlled stop before the hazard can be reached and the color of the WLS27 will change to red as an easy-to-see indication of the breach.

Rapid Deployment

The SX5-B has a compact, one-piece design that installs easily in any location without requiring time-consuming alterations to area infrastructure. Device setup is easy using Banner’s free configuration software which features intuitive, menu-driven tools that guide users through each step in the process.

Versatile Protection Zones

The SX5-B will scan a 275° area around the device to create warning zones of up to 40 m and safety zones of up to 5.5 m at 70 mm resolution or up to 3 m at 40 mm resolution. It will reliably safeguard large, complex, and irregularly shaped areas that would otherwise be protected by a combination of hard guarding, safety mats, and safety light curtains or grids.

Reliable Operation in Industrial Environments

The innovative optical design and advanced filtering capabilities offered by the SX5 enables best-in-class immunity to dust, dirt, and light interference to minimize false trips caused by environmental conditions. Users can select the level of filtering and response time that best suits their application using the configuration software.

Increased Machine Uptime

The SX5-B has on-board LED indicators and a large multi-segment color display that provide at-a-glance system status information so users can quickly identify zone breaches and resolve issues with a minimal amount of equipment downtime.

關於操作人員和機械手臂的保護應用的目標, 使操作人員能夠最大限度地操作檢查工作站,同時保護操作人員免受危險威脅。為此應用提供區域安全防護的重要性, 是偵測人員入侵並提供停止訊號,並在檢測站中提供持續的感測。

在這個工作區中,機械手臂在材料沿著輸送帶移動時拿取材料並將其放置在包裝中,操作人員使用檢查站來確保包裝中填充了正確數量和類型的材料。為了實現最高的生產效率,操作人員不得誤入保護區域(紅色區域),這點非常重要。

描述

對於使用者工作效率和人身保護具有同等重要地位的應用,安全雷射掃描器能提供量身訂做的安全防護。Banner的AG4安全雷射掃描器具有190º的掃描角度,幾乎適合任何形狀的區域,可以根據工作距離和旋轉角度來評估操作人員的位置。當工作區尺寸和參數改變時,其靈活性允許為新的設定區域提供防護。

AG4在指定的保護區域內提供警告區域(綠色區域)和保護區域(紅色區域),提示機械完全關閉之前提醒與機械手臂靠近的人員。檢測到物件時,AG4計算其位置; AG4會允許機械手臂在警告狀態偵測期間繼續運行,或在有物體誤入保護區域偵測範圍時強制關閉。

與其他保護裝置相比,安全雷射掃描器可以成為極具成本效益的應用安全防護的解決方案。若在危險工作區區域使用安全地墊,地墊的價格很高之外,地墊元件的磨損很快。其他機器安全防護選項包括防護欄障和閘門,它們可有效保護一個區域,但會限制操作人員的進出。AG4安全雷射掃描器提供最佳的方式管控人員進出,以加快檢測過程並提高生產效率。