Edge Guiding for Battery Manufacturing

Edge guiding in battery manufacturing ensures that films of material are centered on rolls within tight tolerances. Poor edge guiding can create waste or compromise the quality of the final product. Detecting the smallest misalignments helps prevent these costly errors by enabling real-time adjustments. This article explains how fiber optic sensors create a precise and reliable edge guiding solution for battery assembly.

Lithium-ion battery assembly combines rolls of anode, cathode, and separator film into a larger roll of battery cell material. Misalignment of the three materials can cause waste, can jam the machine and lead to unplanned downtime, or result in product recall. Even small variation to the left or right can reduce the quality of the final product. To ensure quality and keep production running smoothly, the edges of the battery materials need to be precisely aligned throughout the process. A solution is required that can detect minimal misalignment in both directions and initiate automatic adjustments.

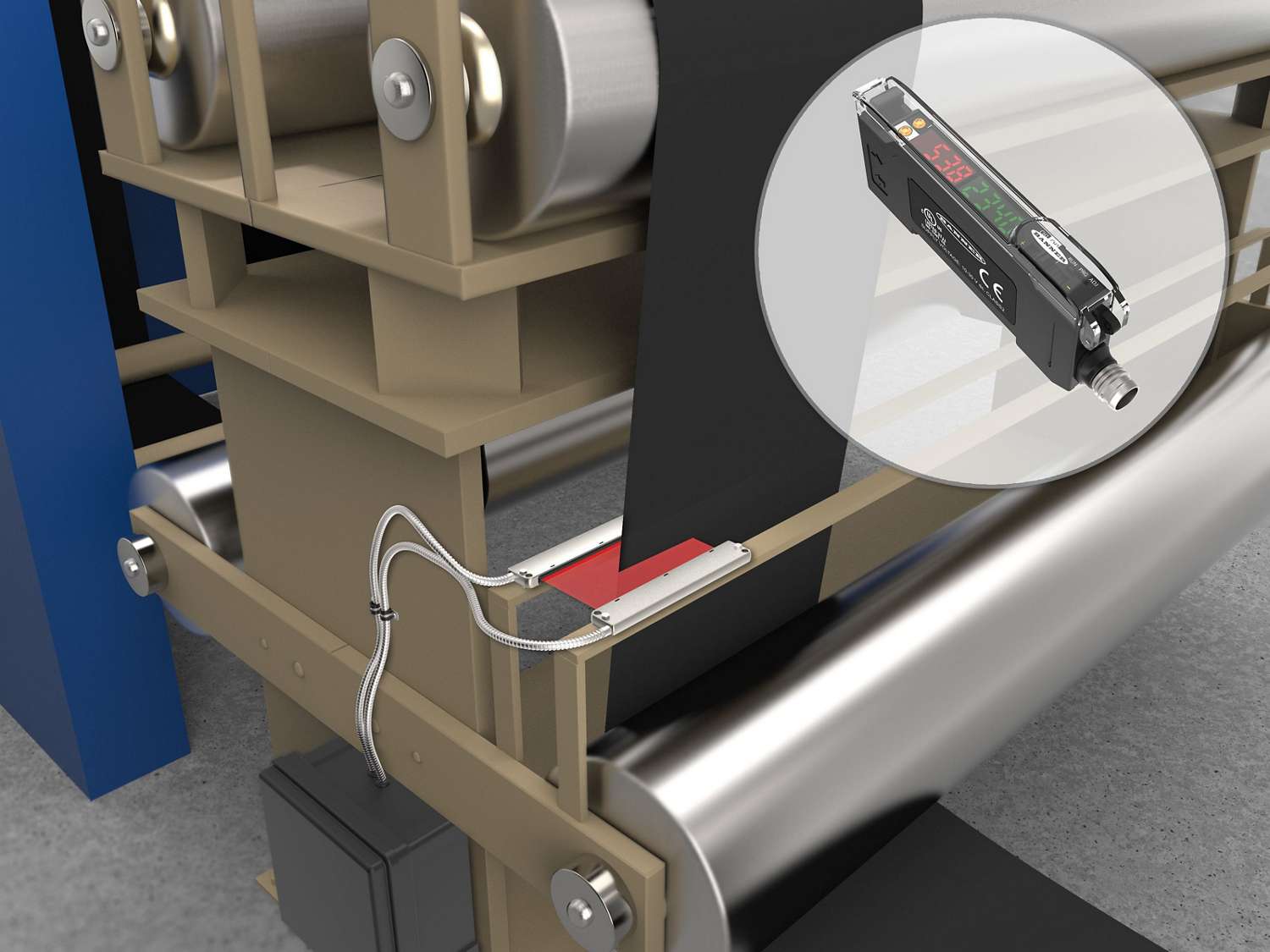

A high-power fiber optic amplifier like the DF-G3 Series, paired with a plastic fiber array, ensures material is aligned correctly by precisely detecting the material’s edge. The fiber optic assembly reliably identifies the edge of the material based on the light intensity resulting from fully or partially blocked beams. For example, if the material blocks half of the beams, the film is centered on the roll and no adjustment is necessary. If the material shifts to the left or right—blocking more or fewer beams and changing the light intensity within the specified tolerance—the machine uses the real-time sensor data to automatically adjust the roll and realign the material.

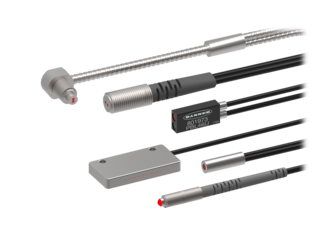

Fiber optic systems offer many advantages for edge guiding applications in battery manufacturing. The fibers themselves are small and flexible enough to fit into areas where space is limited; meanwhile, the fiber amplifiers can be mounted in a more convenient location for programming and troubleshooting.

Banner Engineering offers an extensive selection of fiber optic assemblies, along with a wide range of other industrial automation solutions to supplement your edge guiding applications. Banner provides reliable products with global support to help you find the right technology for your application requirements.

High Precision and High Power

The high-power amplifier and small core fibers create more intense beams of light for precise position sensing of small parts. These powerful light beams can pick up on slight changes that traditional sensors may miss.

Versatile and Flexible

Pairing the DF-G3 with plastic fibers allows for flexible installation. The versatile plastic fibers are bendable and can fit into a wide variety of spaces. Plus, the DF-G3 amplifiers fit into easy-to-access locations for convenient troubleshooting and maintenance.