Measuring Wear Patterns on Conveyor Belts [Success Story]

L-GAGE® LH series laser sensors work together to provide precise belt measurements despite color and surface variations

Customer Requirements: Accurate measurement of steel reinforced polyurethane belts used in elevators

Solution: L-GAGE® LH series laser sensors

Why Banner? Material Versatility – Highly accurate 1024 pixel CMOS linear imager is immune to variations in color and surface sheen

Non-Contact Measurement – Laser displacement sensors will not damage or distort the target or restrict its motion

Customer Benefits

Accurate Forecasting – Precise measurement data from belts enabled better deployment and service planning

Background

Elevators, escalators and moving sidewalks are major investments in any facility’s infrastructure. This equipment is expected to operate safely and reliably for many years and with minimal downtime for maintenance. To meet these expectations, a large-scale manufacturer of vertical and conveyor transport equipment performs rigorous tests on all system components. The data that is collected helps the company estimate component life expectancy and plan service schedules.

Challenges

The company uses elevator belts made of polyurethane reinforced with steel. Belt surfaces range from matte to glossy and vary in shades of black and gray. Tests conducted on the belts replicate years of use. Digital calipers used to measure the resulting wear patterns caused surface distortions, leading to inaccurate measurements. Laser micrometers were also employed to measure belt wear, but variations in color and finish led to numerous inconsistencies in the results.

Solution

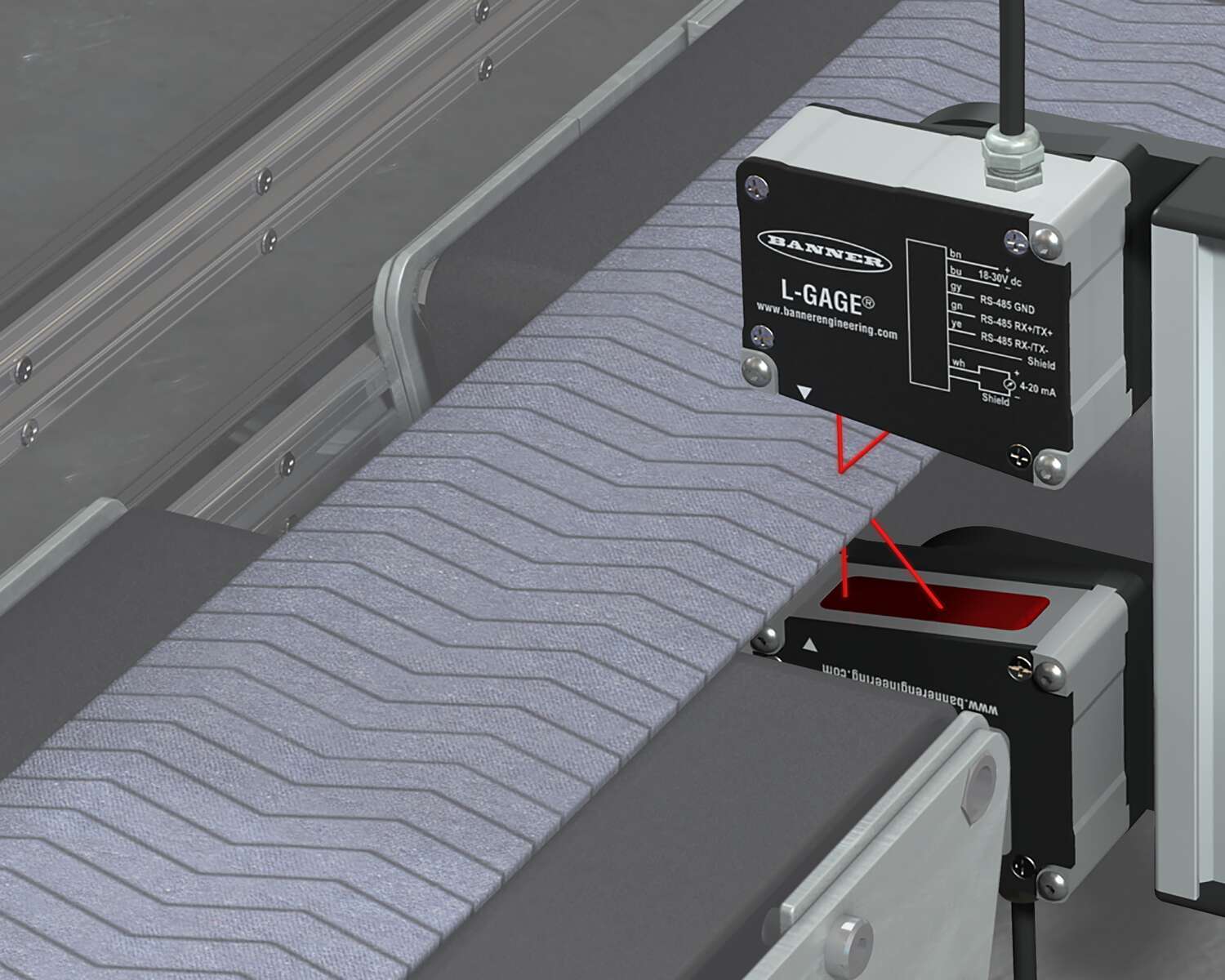

The company installed two L-GAGE® LH series laser sensors on either side of the elevator belts. Configured to work in coordination with each other, the sensors take continuous, non-contact thickness delta measurements of the belts while they are being tested. These measurements are used to determine wear patterns on the belts, allowing the company to make more informed choices regarding deployments, life expectancy and service intervals.

L-GAGE LH series sensors use optical triangulation and feature a high resolution 1024 pixel CMOS linear imager to make precise distance measurements. The CMOS imager is capable of micrometer level resolutions and is immune to variations in color and surface sheen, making it ideal for applications like this where precise and reliable measurements are vital to making accurate forecasts.