Tension Loop Control for Clear Plastic

Application: Monitor plastic film loops

Challenges: Clear plastic at various distances

Solution: S18U ultrasonic sensor

Benefits: Sound waves detect surfaces regardless of color or transparency

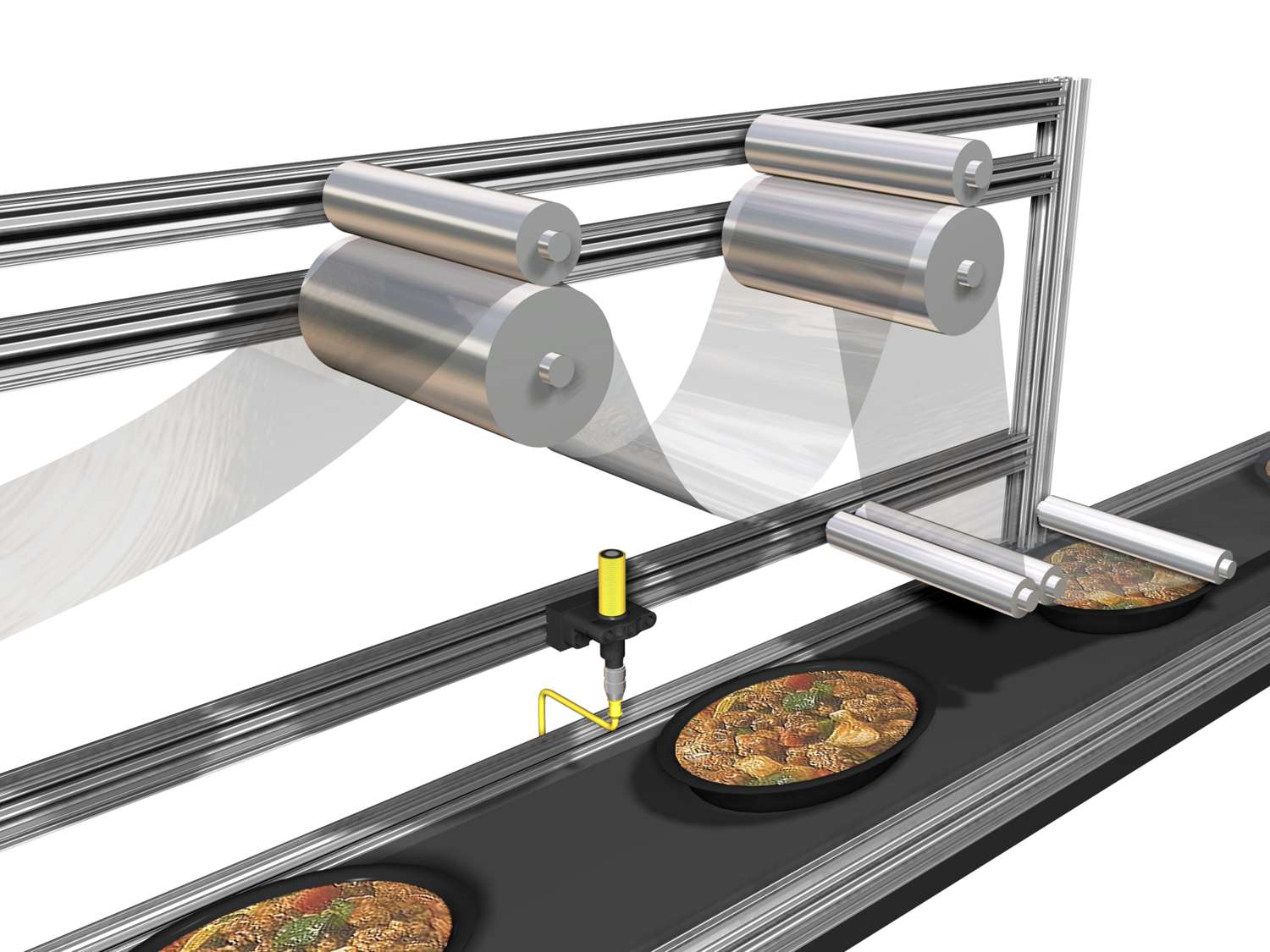

Plastic film wrapping of food trays is made more efficient by applying the film as the trays move down a conveyor process. The film must be fed evenly across the trays, but this must also be done while ensuring the film is not torn or broken. A loop in the feeding process is used to manage the tension, preventing broken film, and ensures the film wrapping process continues smoothly without interruption. To monitor the loop, an ultrasonic sensor is used to detect the clear film and report its status to the controller.

Web Break Detection Using Ultrasonic Sound Waves

In this application, monitoring of the tension loop control is done by an ultrasonic sensor, the Banner S18U. The S18U bounces sound waves off of the clear plastic for a reliable and consistent sensing application. Standard photoelectric sensors have difficultly detecting clear material, particularly if its condition changes – in this application, the loop will fluctuate.

As the loop fluctuates, its distance from the S18U also changes. The sensor continuously reports the measurement of the loop changes back to the system controller via an analog output, either 0 to 10V dc or 4 to 20 MA, depending on the model. The controller then uses the analog output information from the S18U to adjust the speed of the film and maintain a consistent loop and proper film tension.

The S18U is also equipped with temperature compensation for consistent sensing performance, eliminating additional setup and configuration if the ambient temperature varies widely or changes.