Industrial LED Strip Lights or Off-the-Shelf Strip Lights: How to Choose?

When deciding whether to buy industrial flexible strip lights or off-the-shelf strip lights, there are several factors to consider: functionality, durability, and cost-effectiveness. While both types of strip lights have their advantages, you should learn the differences between them to determine which one is best for your application.

Advantages of Industrial LED Strip Lights

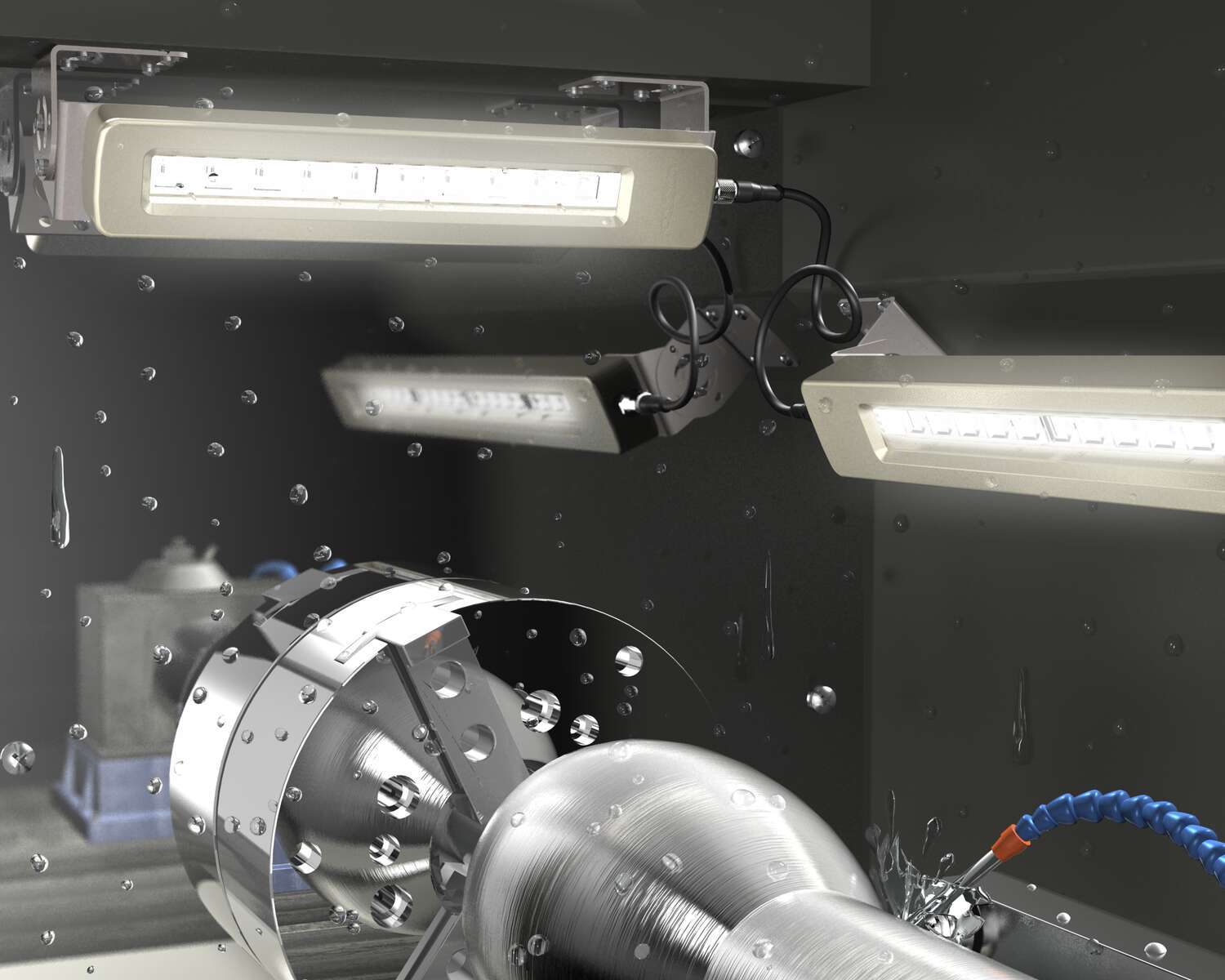

Heavy-duty LED strip lights provide reliable operation in the most challenging environments, including high-pressure washdown and all kinds of weather. Their housing is built with rugged construction for dependable performance in a variety of tough applications, including food and beverage, packaging, and automotive assembly. LED technology saves energy and minimizes replacement costs.

Advantages of industrial strip lights over consumer grade strip lights:

- Durability: Industrial strip lights are built to withstand harsh conditions, making them ideal for environments with moisture, washdown, variable temperatures, dirt, and grease. Housing materials are far more robust than those on consumer grade lights. For example, industrial strip lights commonly use silicone-encapsulated housing, which ensures resistance to water, shock, and vibration. This rugged housing with some UV-resistance allows for use outdoors and in industrial facilities. Not all consumer grade lights have industrial approvals, such as CE and UL.

- Flexibility: Bendable industrial strip lights enable users to wrap them around curved surfaces, corners, and angles. You can cut RGB LED strip lights to the needed length and customize them into unique shapes. Mounting clips allow users to create unique shapes.

- Higher IP Ratings: Ingress Protection (IP) environmental ratings indicate a light’s level of protection against water and dust. If a strip light is rated IP69K, for example, that means it is dust-tight and can withstand a wide range of temperatures and high-pressure washdown. Knowing the IP rating is important when choosing where to install a strip light, with a higher environmental IP rating giving confidence to install an industrial strip light in a broader range of locations.

- Customization and Programmability: Programmable industrial strip lights allow users to configure color, animation, sounds, and intensity for advanced indication, illumination, and inspection applications. These devices are ideal for those who are looking for advanced capabilities not found in traditional lights.

- Longevity: While the up-front costs of industrial LED strip lights are typically higher than consumer grade options, they often have a longer lifespan. Their rugged housing, quality components, and advanced circuitry make them more likely to survive impact and unstable electrical conditions, and have a much greater everyday durability, requiring less frequent replacement. The reliability of these lights, combined with their advanced control capabilities, can help reduce downtime by providing clear status indications and facilitating quicker responses to issues.

- Easy integration: RGB LED strip lights with industrial protocols can be integrated into existing industrial control systems, making them easier to manage and control within the large industrial setup. They typically support industrial architectures like IO-Link and discrete I/O, allowing RGB LED strip lights to be synchronized with other equipment and processes. This can be used for signaling, status indicators, or automation.

Heavy-duty LED strip lights provide reliable operation in the most challenging environments, including high-pressure washdown and all kinds of weather. Their housing is built with rugged construction for dependable performance in a variety of tough applications. LED technology saves energy and minimizes replacement costs.

Industrial strip lights have some advantages over off-the-shelf strip lights:

- Durability: Industrial strip lights are built to withstand harsh conditions, making them ideal for environments with moisture, extreme temperatures, and water. Housing materials are far more robust than those on off-the-shelf lights. For example, where basic strip lights may use silicone or PVC, industrial strip lights commonly use aluminum or copolyester housing, which ensures resistance to water, shock, and vibration. The rugged housing on these lights allows for use in outdoor and in industrial facilities.

- Flexibility: Bendable industrial strip lights enable users to wrap them around curved or flat surfaces. They can be cut and customized into unique shapes.

- Higher IP Ratings: Ingress Protection (IP) environmental ratings indicate a light’s level of protection against water, dust, and other elements. IP69K is the highest ranking on the IP rating scale, which means it is dust-tight and can withstand chemicals, a wide range of temperatures, and high-pressure washdown. Knowing the IP rating is important when choosing where to install a strip light, with a higher environmental IP rating giving confidence to install an industrial strip light in a broader range of locations.

- Longevity: While the up-front costs of industrial strip lights are typically higher than off-the-shelf options, they often have a longer lifespan. Their rugged housing makes them less likely to break due to accidental impact and have a much greater everyday durability, requiring less frequent replacement.

- Cost-Efficiency: LED lights provide low-power, maintenance-free illumination, drawing very little electricity compared to traditional incandescent or fluorescent lighting. They require no bulb or ballast changes, saving time and expense. An industrial LED strip light may also have dimming control to protect product lifetime and let operators set the brightness to their comfort level or other needs.

- Customization and Programmability: Programmable industrial strip lights allow users to configure color, animation, sounds, and intensity for advanced indication, illumination, and inspection applications. These devices are ideal for those who are looking for advanced capabilities or flexibility beyond traditional lights. To better align with specific application requirements, industrial strip lights are more likely to have custom features. For example, Banner offers several customization options, such as custom logos and labeling, marking, configuration, connectivity, and kitting and bulk packaging.

Advantages of Off-the-Shelf Strip Lights

Off-the-shelf strip lights serve as a cost-effective alternative for those who are looking for basic functionality. They are widely available, which makes purchasing and replacing simple. Off-the-shelf strip lights are ideal for residential use and in spaces where durability is not a necessity.

Off-the-shelf strip lights have some advantages over industrial strip lights:

- Price: Off-the-shelf LED strip lights typically have lower initial costs than industrial strip lights. This makes them a more budget-friendly choice for general lighting applications in which advanced features and rugged housing are not essential.

- Flexibility: Like industrial strip lights, basic rope lights can be bendable and cuttable as well. Mounting clips allow users to create unique shapes. Some soldering may be required.

- Availability: These lights are readily available online and in-stores. Their straightforward designs can be manufactured in bulk for quick turnaround.

- Installation: Off-the-shelf strip lights are commonly designed for simple installation in residential areas and other settings in which environmental conditions are not a concern.

Choosing Between Industrial Strip Lights and Off-the-Shelf Strip Lights

For reliable performance in harsh conditions, customized features, and programmable color and animations, an industrial LED strip light is the preferred option. Those who favor simplicity over longevity may select an off-the-shelf strip light. Both have flexible options, though industrial strip lights tend to be considerably more durable and can be trusted for indoor and outdoor use.