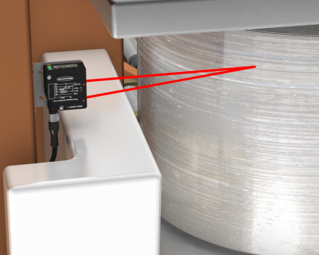

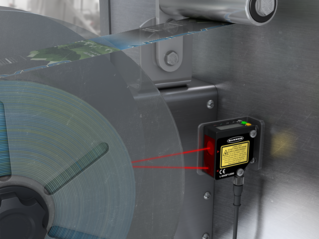

飲料包裝收縮膜貼標機解決方案

收縮膜貼標通常用於飲料包裝,因為它們很容易依照的物體獨特形狀包裝,並提供360度的的包裝覆蓋,讓品牌曝光機會增加到最大。高速收縮膜貼標機器在各種瓶子和罐子快速通過輸送帶時,將標籤貼在上面。

由於收縮材料的低廉成本,還有這類標籤提供的強有力的視覺效果,近年來收縮膜貼標機變得非常受歡迎。收縮膜套標級的環形包裝能在整個容器四周形成搶眼的360度圖案。這一點很重要,因為它增加產品在貨架上的能見度,而且比其他貼標選項為更耐用。

收縮膜貼標機是飲料裝瓶生產線上非常關鍵的一步,因為這個區域是經常頻繁更換作業的地方,具有堵塞或減緩生產速度的高風險,且必須在快節奏的環境中有良好效能。

![高速收縮膜套標[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/QS18VN6LLPQ5-Shrink-Sleeve-Bottle-Labeling.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)