飲料:第二階段包裝

飲料裝瓶生產線上的第二階段包裝,始於貼標到裝滿和密閉的飲料容器。必須檢查每個標籤的準確度、外觀和位置。產品召回時日期/批次代碼至關重要,必須清楚準確地印在每個容器上。然後將容器一起包裝在紙箱內、箱子內、泡殼托盤上,或者以收縮膜包裝在一起。每個包裝中必須裝填正確的容器數量並加以妥善密封。

第二階段包裝飲料應用

按機器類型查看應用程式

特色應用

在列印機上觸發感測

在飲料業,所有產品的日期/批號都是強制性的,以確定產品的製造時間和地點。必須找到一個解決方案,可以準確識別瓶蓋,然後觸發機器將日期/批次代碼列印到瓶子上。

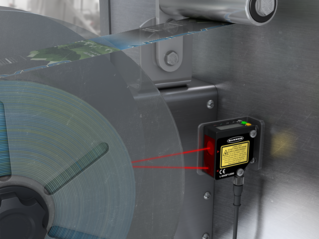

Roll Diameter on Labels

In the beverage industry, labels need to be applied to the bottles quickly and without error to keep production levels high. Accurately monitoring the thickness on a spool of labels and controlling the unwinding speed is very important for the process to run smoothly. A solution is needed that can accurately supervise and report the material levels on a spool in order to prevent it from running out during the manufacturing process and delaying production.

Registration Mark Detection on a Labeler

Banner Engineering’s R58B Expert registration mark sensor confirms the registration mark’s position on the web. This allows the machine to make minor infeed adjustments to ensure the cut is properly placed and all labels are consistent and complete. If the labels are incorrectly cut they need to be removed from the bottling line creating costly downtime and waste. A quick and easy-to-use sensor is needed to dramatically improve throughput.

日期/批號有無或缺失偵測

An SLM series slot sensor and an iVu Series vision sensorare used to detect bottles passing on the line and to verify that date/lot codes have been correctly printed onto the bottles.

收縮膜標籤有無且標籤正確檢測

P4 OMNI視覺Camera正好位於離開標籤機的瓶子的後面,標籤機確保標籤的呈現將以可重複的方式進行,因此可以與存放的影像進行比較。P4 OMNI密封的防護等級為IP68,採用鍍鎳鍍鋅外殼。

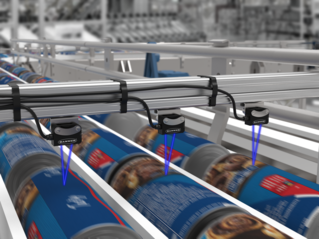

檢測多通道輸送機上的冷藏早餐卷

顏色多變的深色包裝很難用傳統的紅色LED感測器進行檢測。Banner Engineering的微型VS8光電感測器,帶有藍色LED,特別適用於低反射率標籤,可以檢測加壓罐中的冷藏食品。小型感測器適合狹小空間,適用於短距離應用。藍色LED與小光斑配合使用,以最大限度地減少標籤上顏色轉換的影響。

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

High-speed labeler processing 800 bottles per minute

![充填機上氣管識別有無[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![高速收縮膜套標[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/QS18VN6LLPQ5-Shrink-Sleeve-Bottle-Labeling.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)