Status Indication on Airport Conveyor

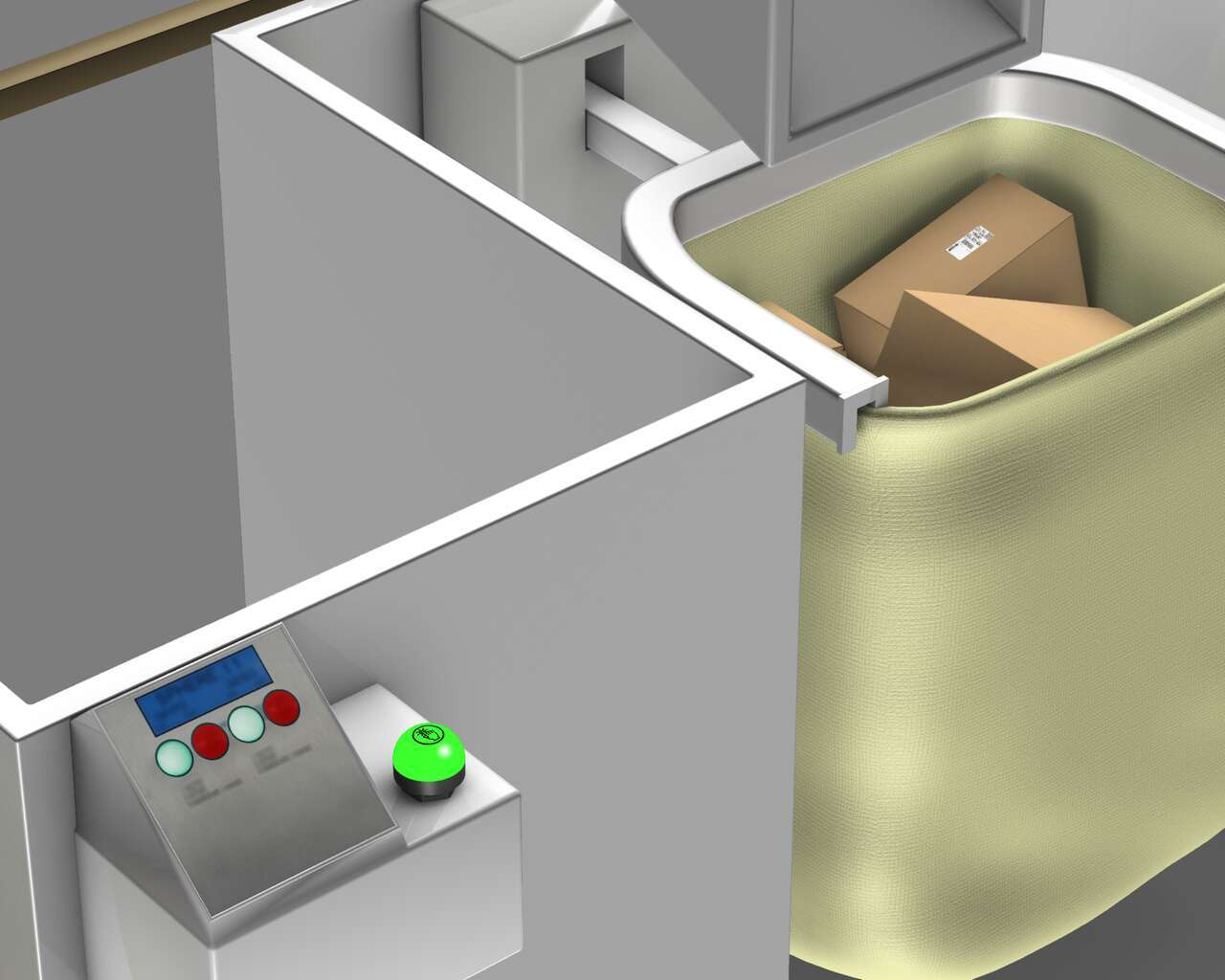

A manager in charge of installing a baggage handling conveyor sought a light to indicate start, jam, and reset conditions with different colors and animations.

Add clarity to every process with combinations of color, interactive control, and audible tones that make process cues and status unmistakable.

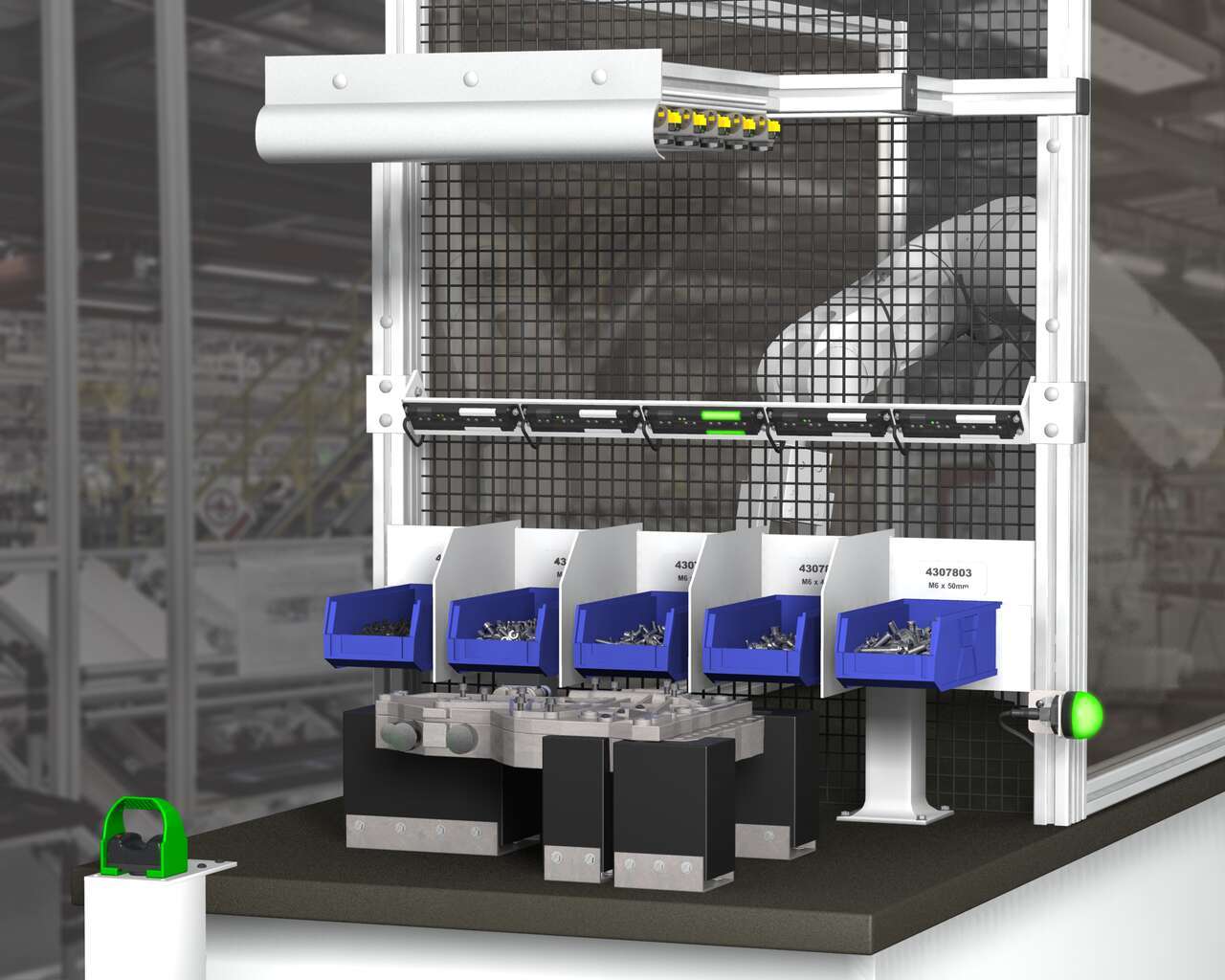

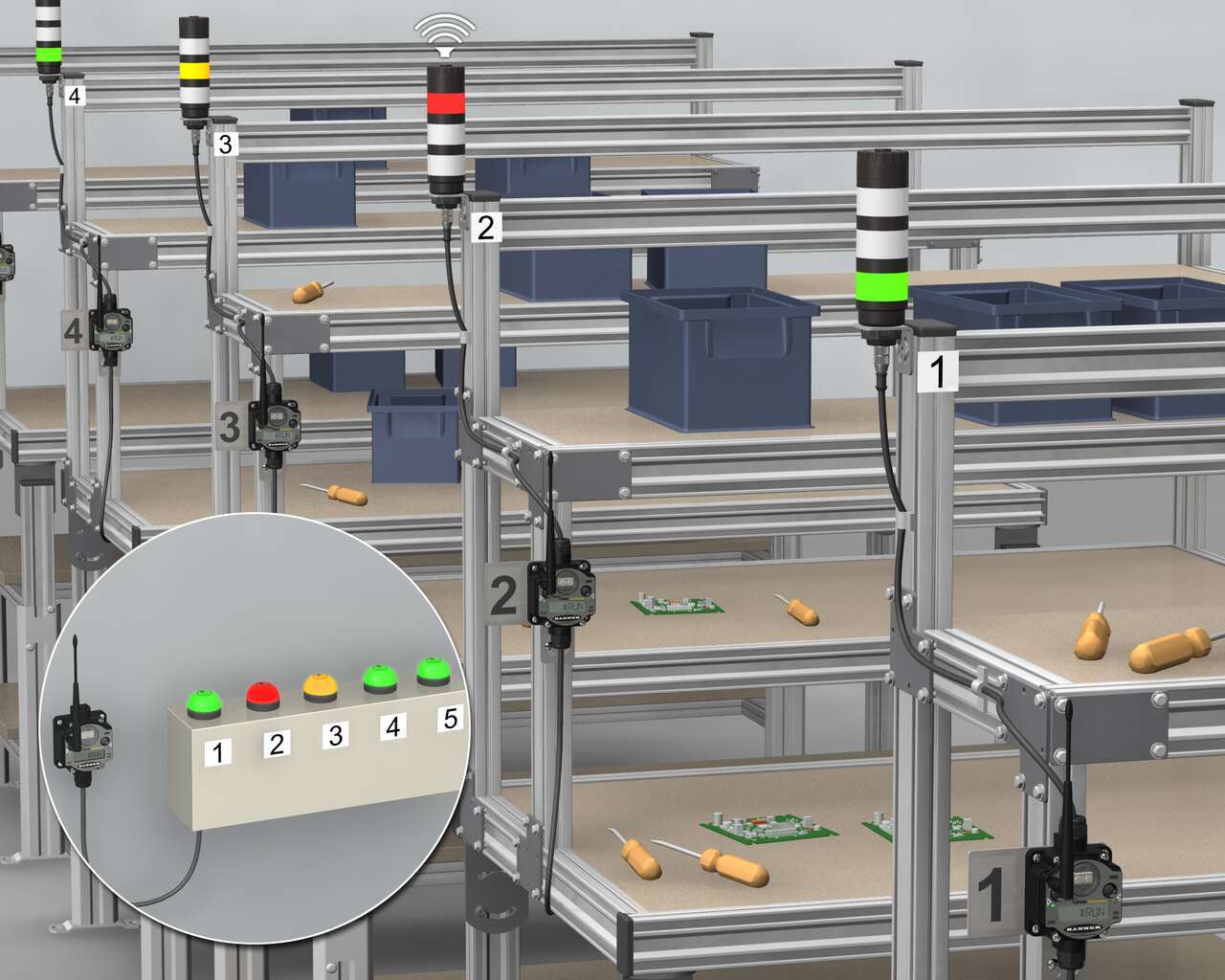

Standard models provide reliable status indication right out of the box, while programmable models extend functionality with configurable response and support for real-time control over IO-Link or Modbus. Color, LED animation, and more can be configured using Banner’s free Pro Editor software or controlled dynamically via protocol. For high-density Modbus systems, models with PICK-IQ, Banner’s high-speed serial protocol, deliver faster visual feedback. For specialized application requirements, models are available for hazardous areas, hygienic environments, outdoor daylight visibility, and localized I/O control.

Whether using discrete signals or protocol-based control, process states become intuitive feedback that guides action, reduces response time, and confirms progress in real time. Where tasks could move faster, awareness could sharpen, or response time could improve—there is a K50 that can make it happen.

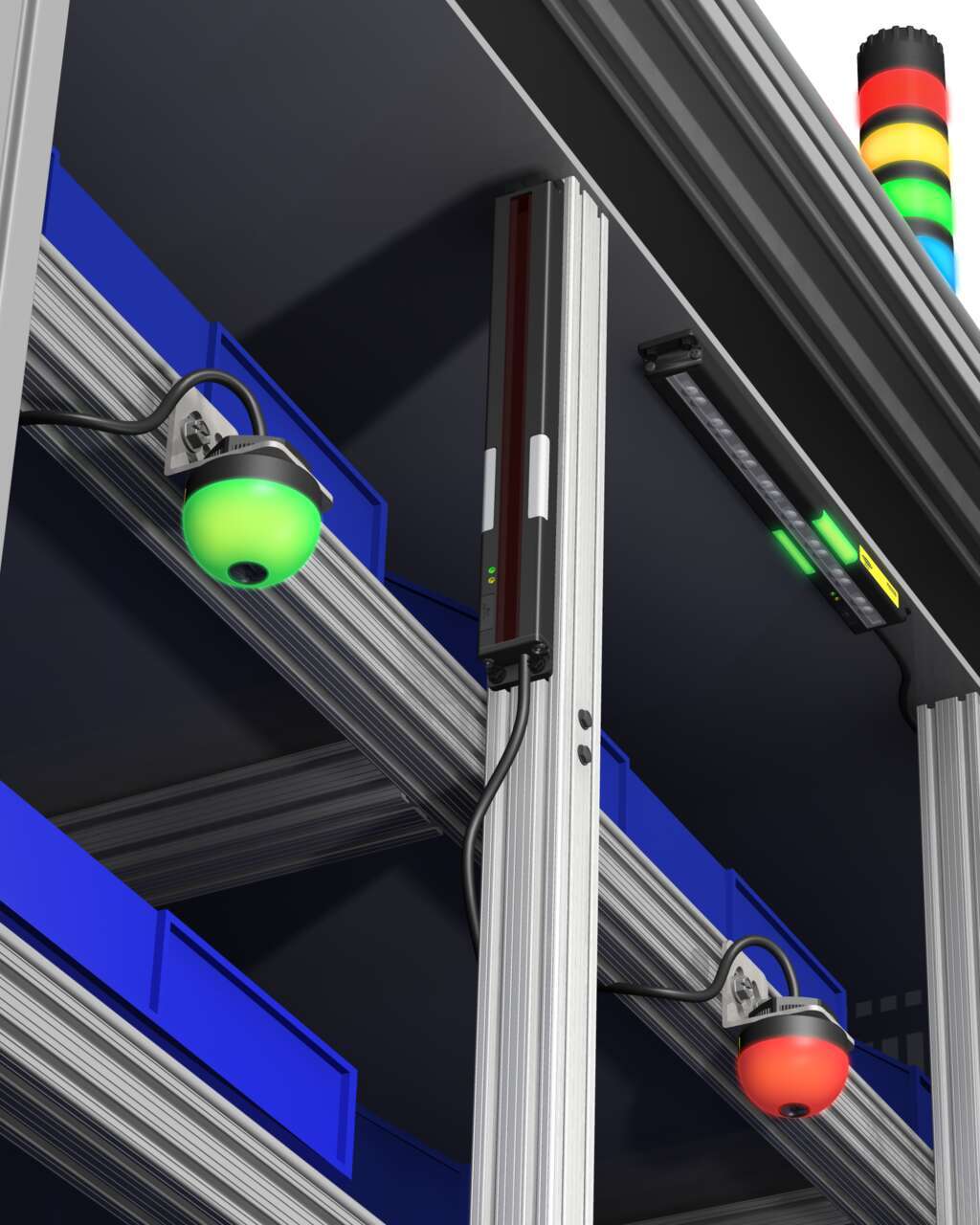

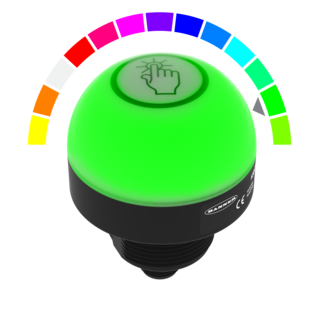

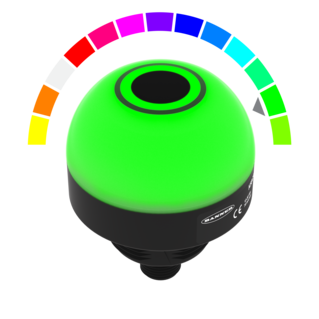

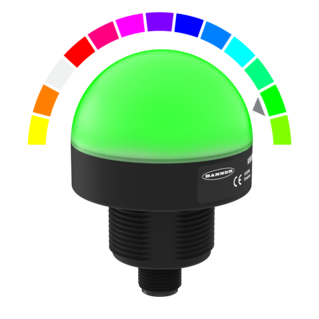

K50 Indicators, Touch Buttons, and Touchless Buttons

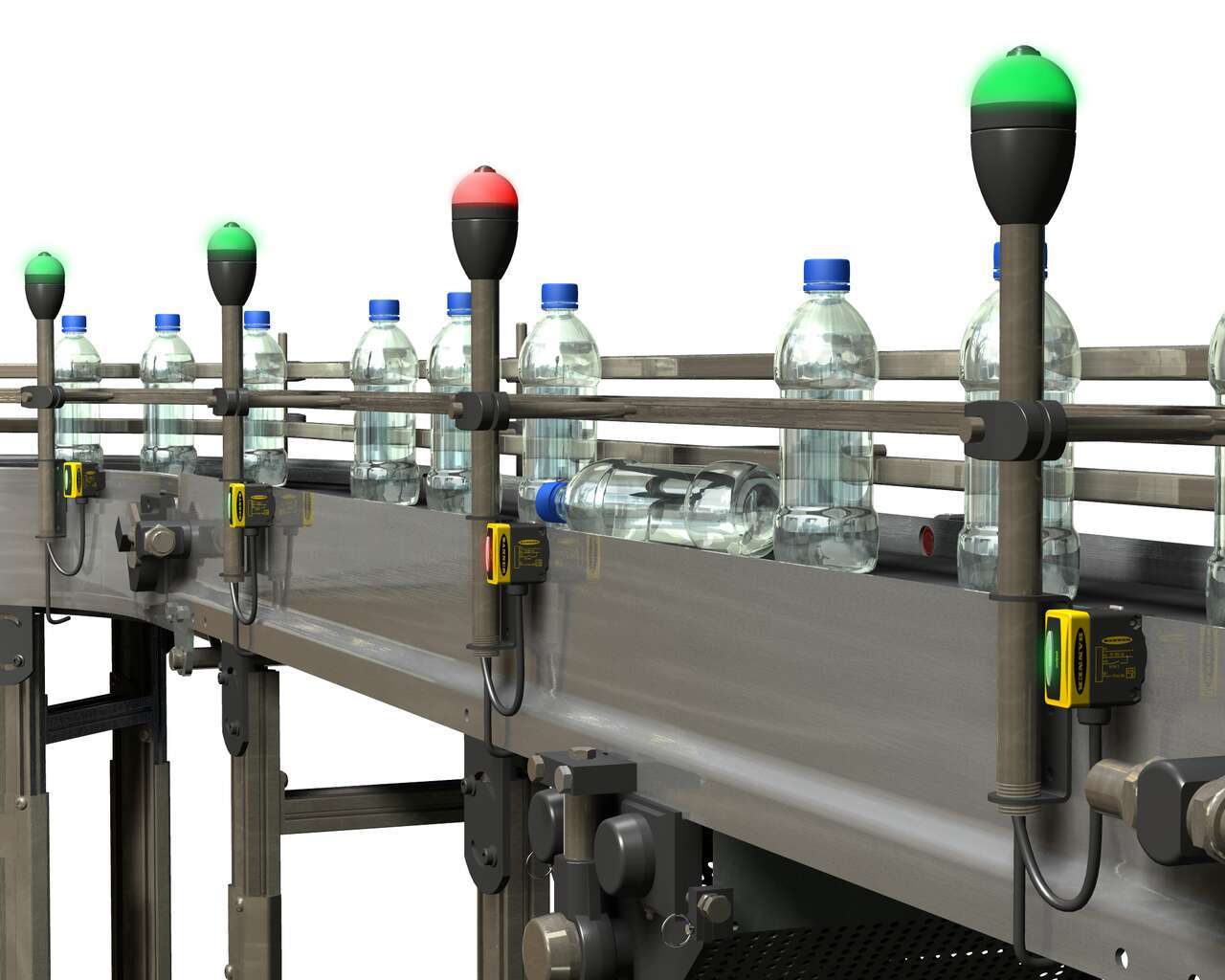

Standard and programmable K50 Indicators cover everything from basic status indication to complex visual signaling across a wide range of applications. Model variants include beacon, audible, and daylight-visible, ensuring unmistakable indication indoors and out, while IP66/IP67/IP69K ratings support long-term performance in demanding conditions.

Standard models offer immediate deployment with up to five fixed colors and are available in compact, domed, and flat pack housings, as well as specialty housings for hazardous zones and hygienic environments.

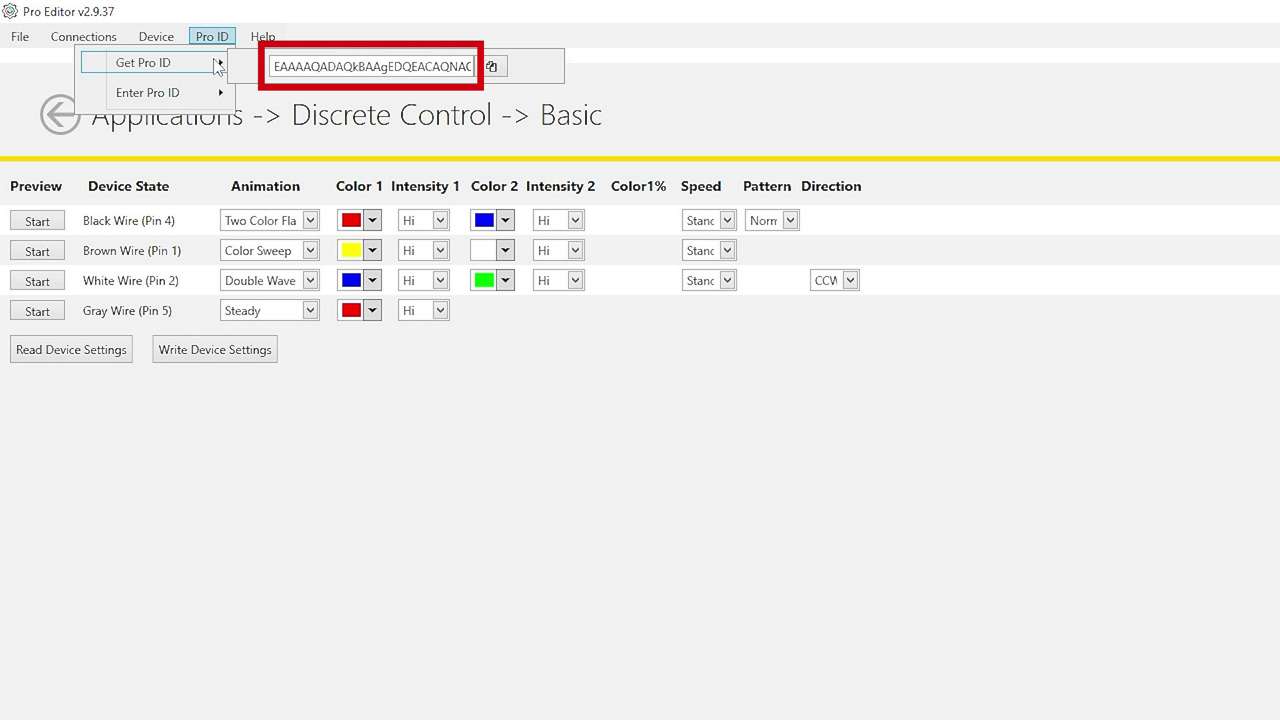

Programmable models provide configurable RGB LED response and support for real-time control over IO-Link or Modbus. 14 colors and 11 animations can be configured using Banner’s free Pro Editor software or controlled dynamically via protocol.

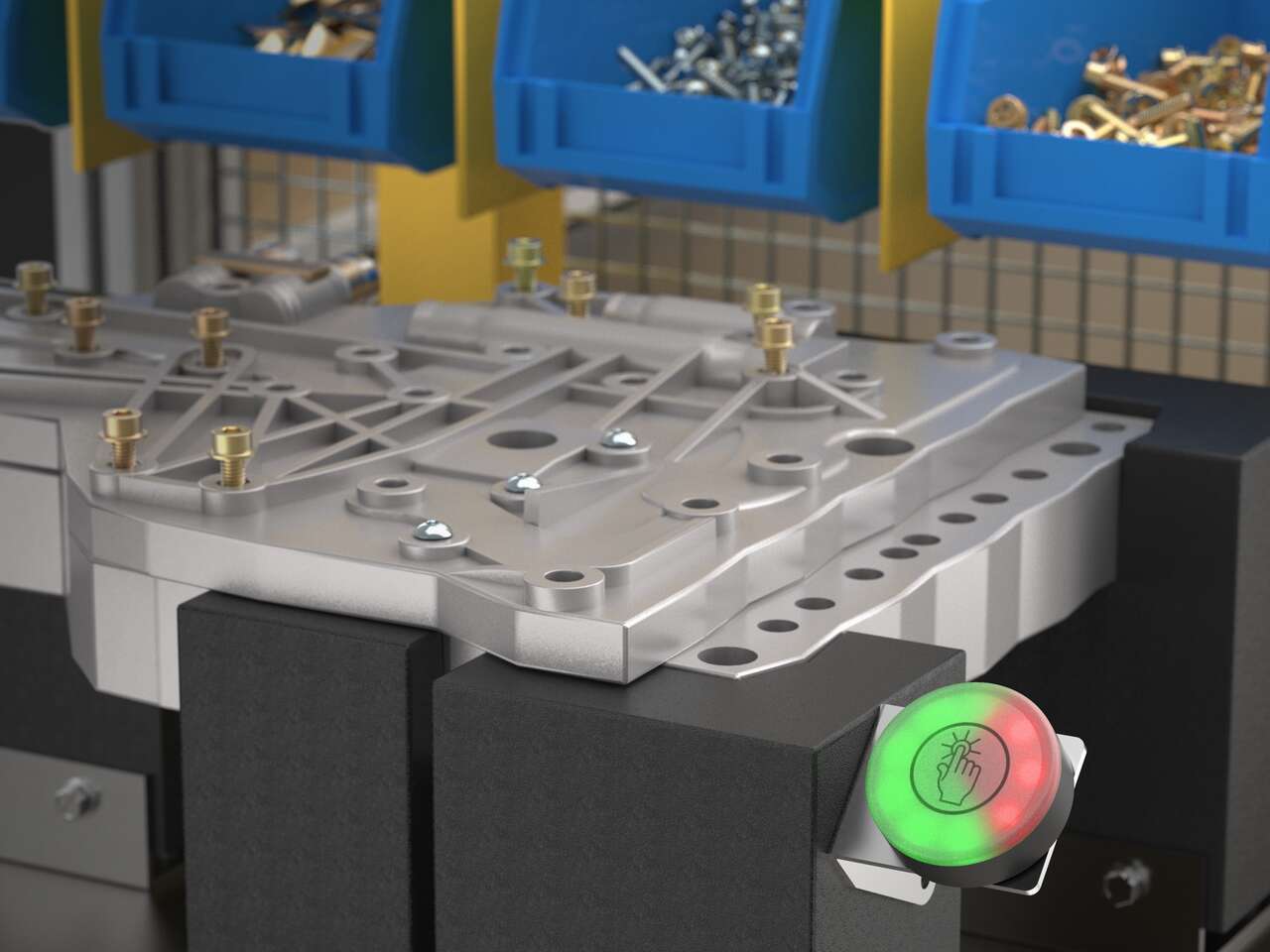

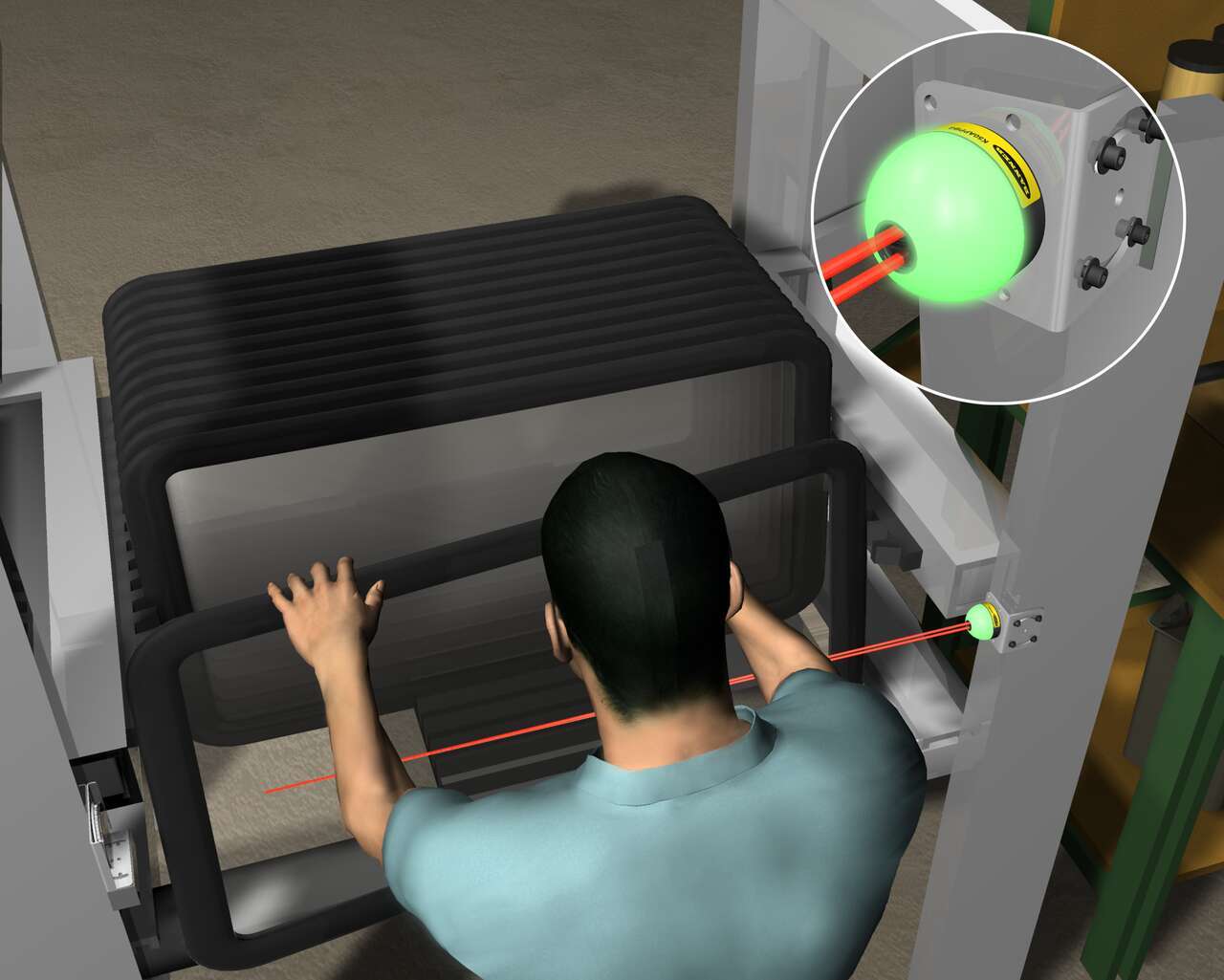

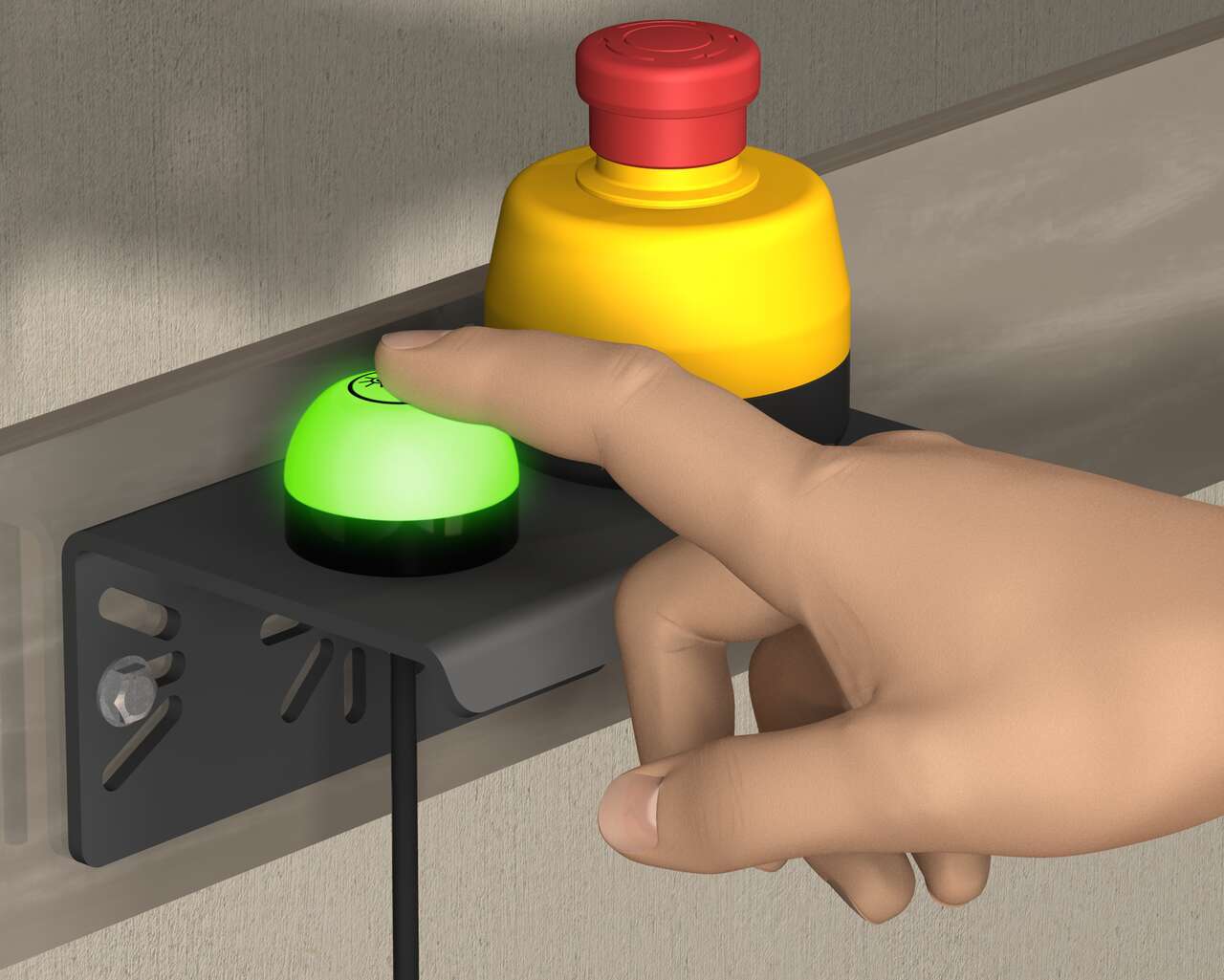

K50 Touch Buttons combine advanced touch technology with unmistakable status indication that translates process signals into clear, interactive feedback. Available in domed or compact housings, all models streamline panel design by replacing multiple conventional buttons with a single device that supports latching or momentary functions and can be operated without pressure—reducing strain and improving ergonomics.

Standard models are ready out of the box with up to three fixed colors, selectable based on input priority. All models are IP66/IP67/IP69K-rated for reliable performance in demanding environments.

Programmable models extend functionality with configurable touch response, multiple I/O modes, and support for real-time control over IO-Link or Modbus. Color, animation, and on/off delays can be configured using free Pro Editor software or controlled dynamically via protocol.

Variants include models with audible output, integrated displays, and FDA-grade housings for hygienic environments.

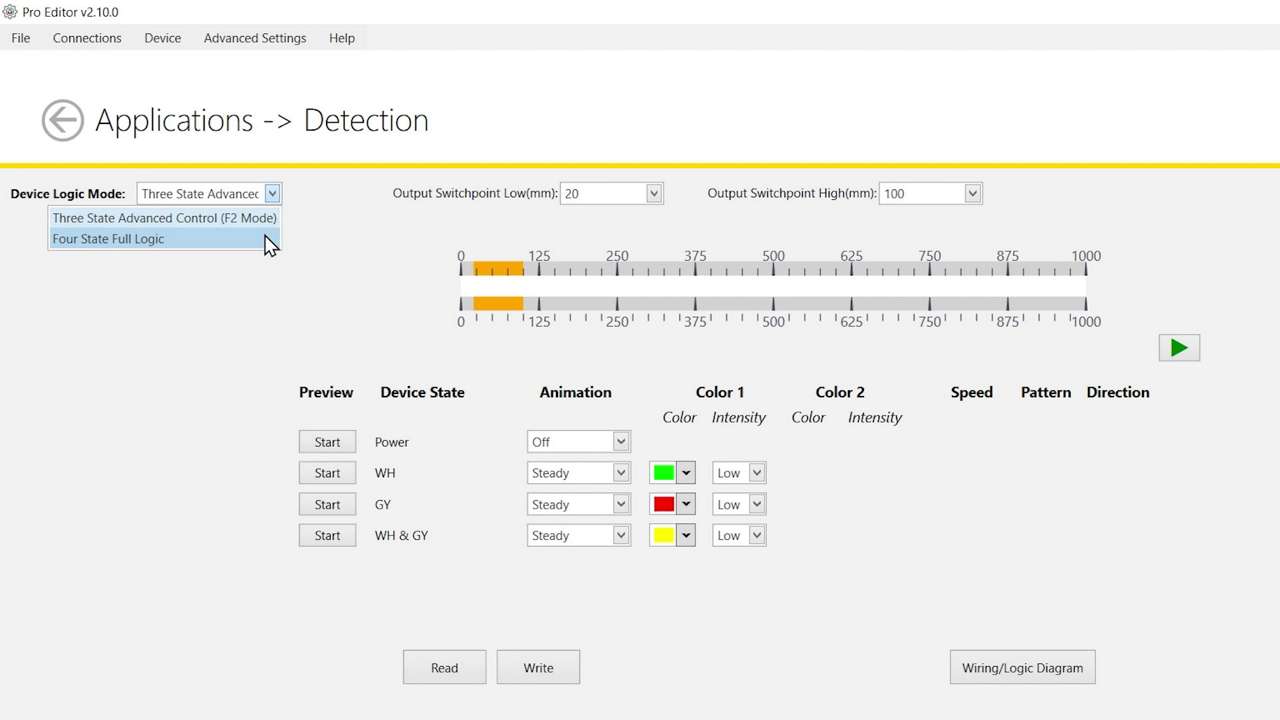

K50 Touchless Buttons deliver reliable, no-contact activation with unmistakable status indication—ideal for reducing touchpoints in high-cycle applications. Configurable optical sensing from 20 to 1000 millimeters ensures responsive operation tailored to the task. 14 color options, 11 animations, and on/off delays—all configurable using free Pro Editor software or controlled dynamically via IO-Link or Modbus—provide visual feedback that makes any process more intuitive. Support for Banner’s PICK-IQ protocol enables real-time feedback and faster updates in dense systems.

Lightweight construction provides a cost-efficient solution while maintaining IP66/IP67/IP69K-rated protection for harsh industrial environments. With no moving parts and built-in immunity to ambient light, EMI, and RFI, K50 Touchless Buttons ensure long-lasting, zero-contact control in demanding applications.

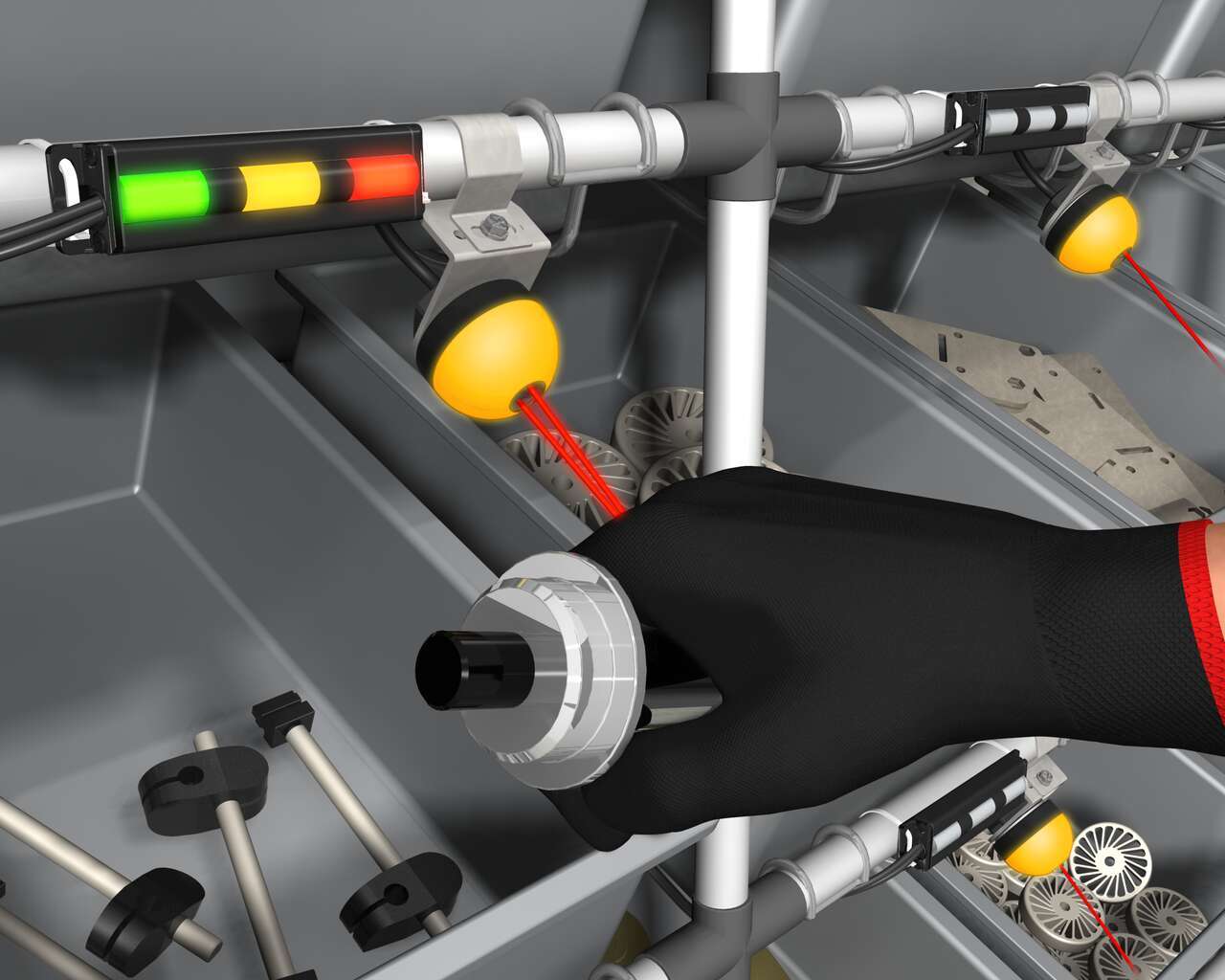

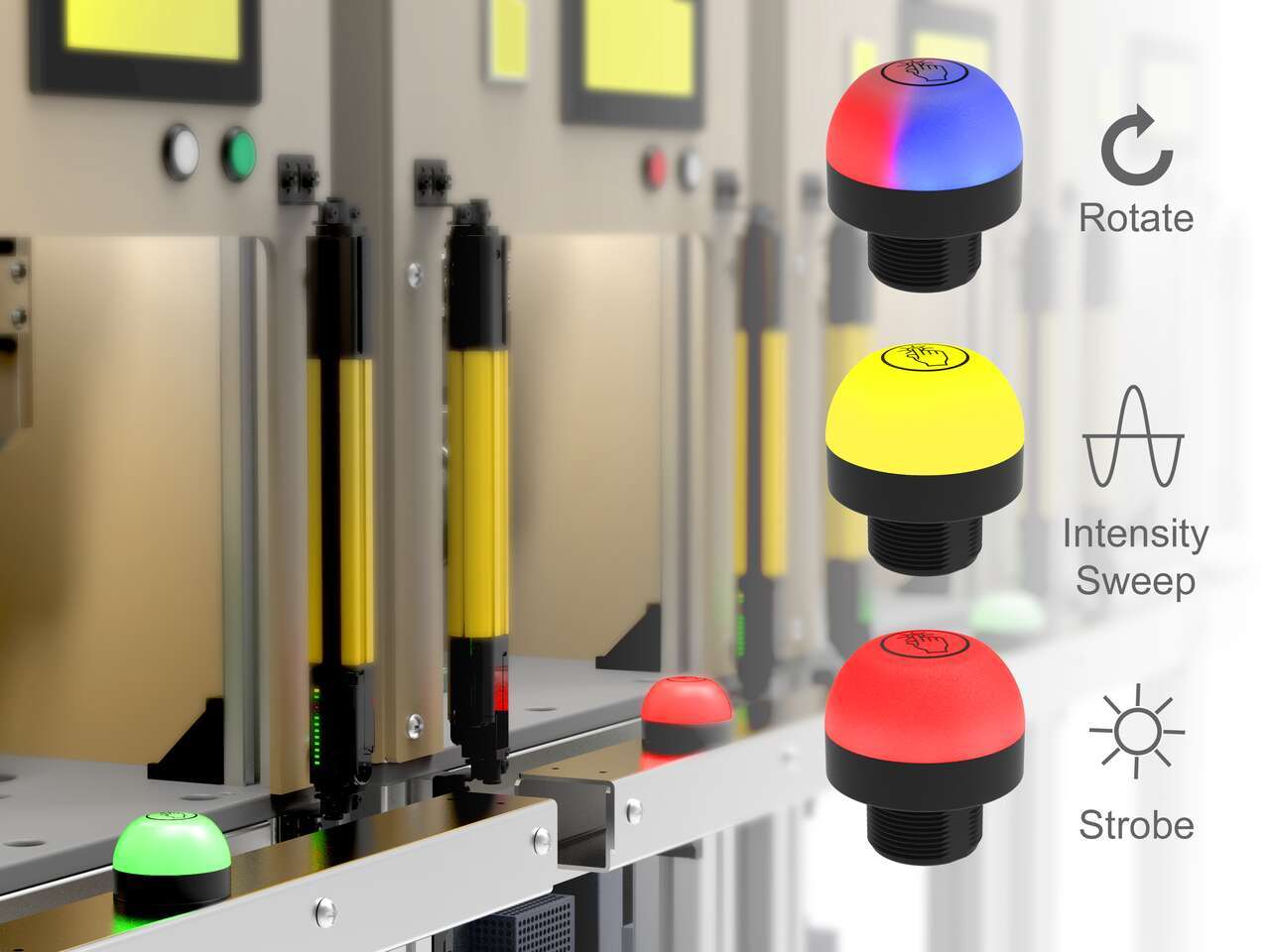

K50 Programmable models provide expanded flexibility and expressive range to communicate status or operating conditions with greater specificity and relevance to each application. Configurable using Banner’s free Pro Editor software or controlled in real time via IO-Link or Modbus, expanded color options, LED animations, and audible tones increase the signaling vocabulary to reflect distinct machine states, guide operator response, or confirm process progress.

LED color is programmable based on machine state, input condition, or system event—providing tailored signaling for each application. Devices offer seven preset colors without configuration, while Pro Editor, IO-Link, or Modbus provide access to up to 14 predefined colors, each of which can be assigned to represent a distinct status, making it easy to adapt signaling behavior with less hardware.

Programmable animations use motion to highlight change, direct attention, or clarify status—helping operators respond faster and more accurately. K50 devices support a wide range of animation types, including flashing, rotating, intensity sweeping, and segment-based effects like chase or fill. These patterns can be tied to machine states, timers, or operator input, helping signal progress or draw attention where it's needed most.

Visual and audible intensity can be set independently to match ambient conditions or application demands. LED brightness can be set to low, medium, or high to optimize visibility without distraction. Sound intensity can likewise be adjusted for clarity in quiet or noisy environments. Intensity settings apply globally or per state and may be toggled through input, IO-Link, or Modbus, depending on the model. All adjustments are made in software with no physical changes required.

K50 Programmable devices with audible capability offer a range of tone types including pulse, strobe, siren, whoop, wobble, continuous tones, and selectable melodies. Each tone is distinct in pattern and character, making it possible to associate specific sounds with particular events, priorities, or response types. Tones can be mapped to states in software and triggered by input or logic conditions, with optional control over playback mode and duration. Configuration is managed through Pro Editor software or controlled dynamically via IO-Link or Modbus.

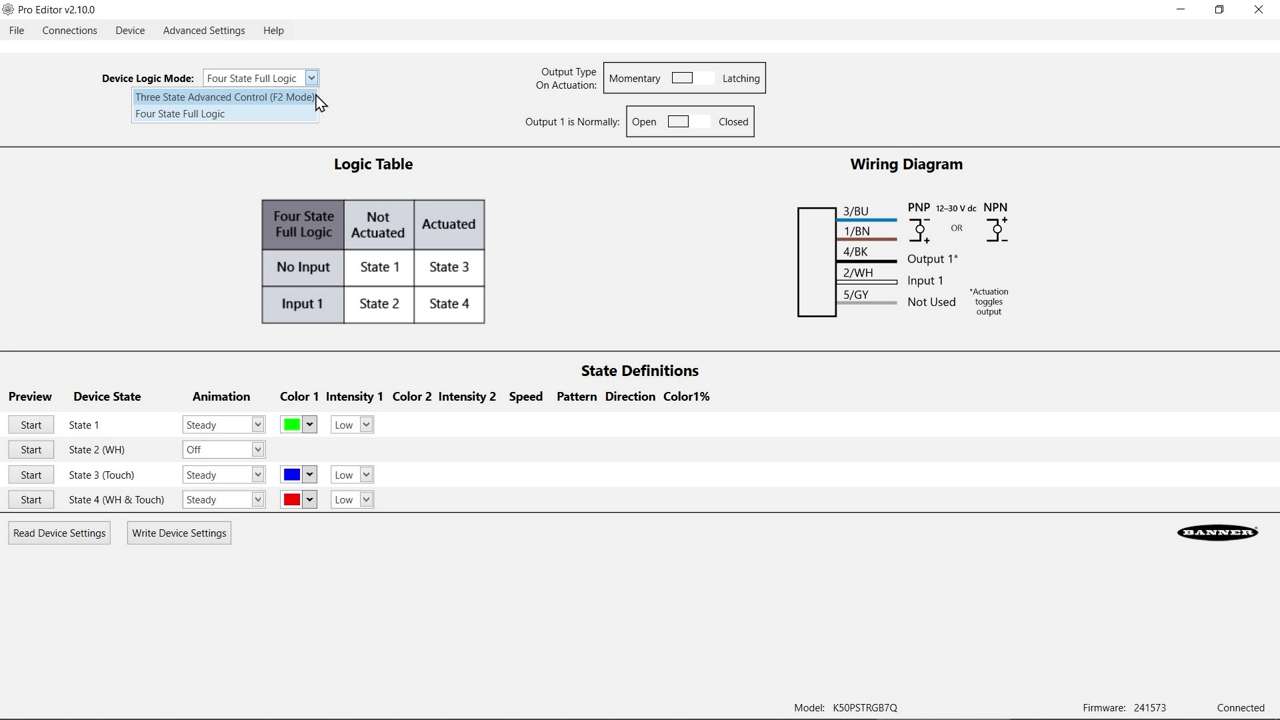

K50 Programmable devices can be configured to respond to inputs in different ways, controlling both the device's appearance and the output signals it uses to control other equipment. Output behavior can be customized to match the role of the device within the system—whether signaling, acknowledging events, or driving downstream actions. Configurable modes include momentary or latching outputs, normally open or normally closed states, and adjustable on/off delays. Models with analog or PWM/PFM outputs can reflect system values or respond dynamically to logic or touch. Logic and control settings are configurable using Banner’s free Pro Editor software or controlled dynamically via IO-Link or Modbus. Options range from basic on/off control to four-state logic, where each state defines a unique combination of output behavior and appearance.

K50 Hazardous Area models are certified for use in applications that require compliance with global hazardous location classifications, including both Zone- and Division-based systems. Built for deployment where clarity and consistency are critical, these models provide up to three state-variable colors in a sealed, impact-resistant housing rated IP67/IP69K. Certified protection methods include intrinsic safety, non-sparking design, and sealed construction to prevent ignition of flammable gases or dust.

FDA models are constructed with compliant materials and laser-marked labeling to withstand frequent high-pressure washdowns without risk of label degradation or false triggering. A fully sealed housing rated IP67/IP68/IP69K resists ingress from spray, foam, and oils—ensuring reliable signaling and interaction through repeated cleaning cycles. Available as indicators or touch buttons, these models support clear communication and consistent performance in demanding, hygienic production applications.

A manager in charge of installing a baggage handling conveyor sought a light to indicate start, jam, and reset conditions with different colors and animations.

客戶需要一個解決方案,透過在堆高機的儀表板上放置指示燈來增加堆高機操作員的響應時間,還可以讓堆高機操作人員確認該請求,從而消除了多個操作人員的冗餘部件交付。

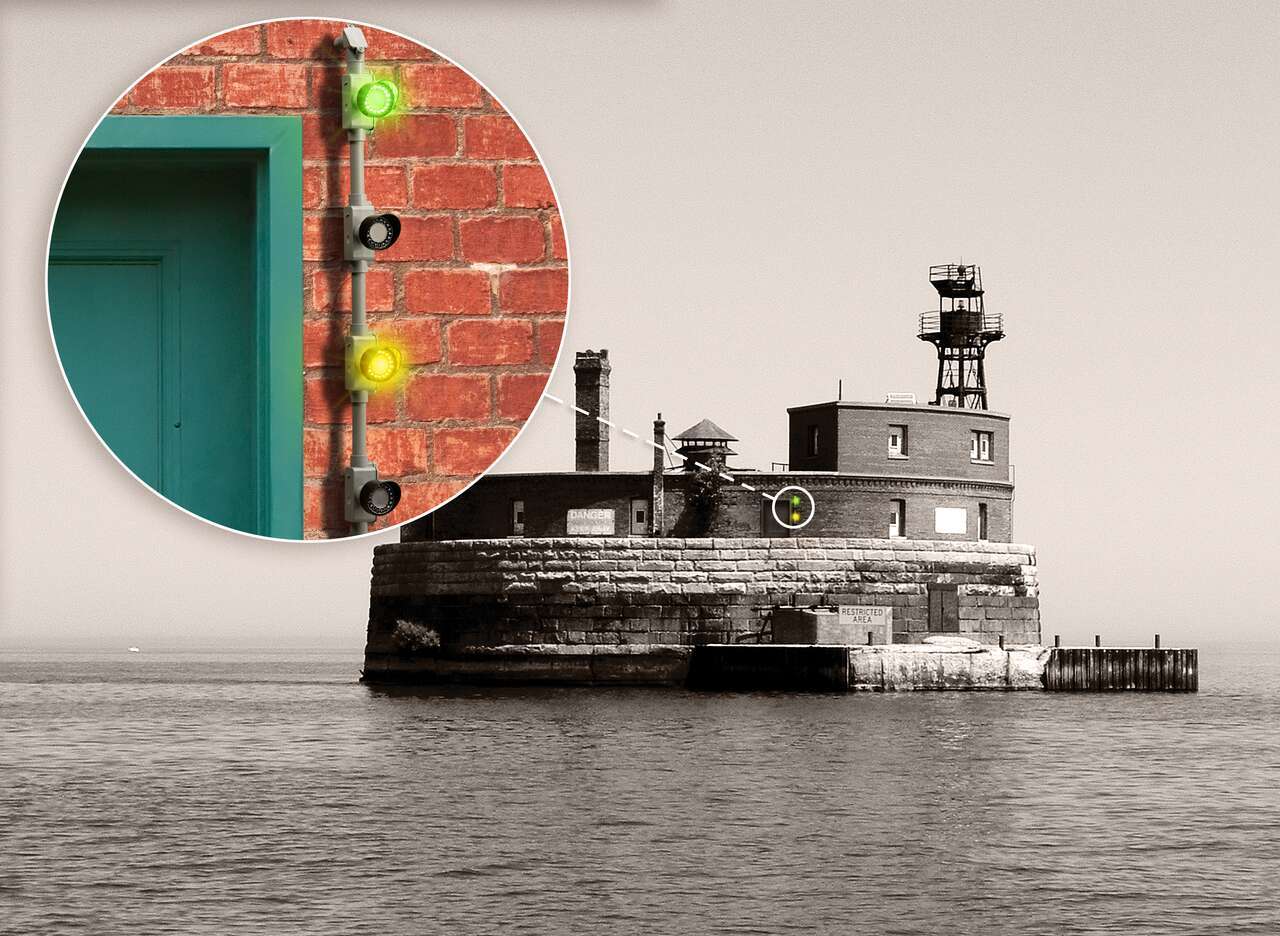

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

K50 Pro touch buttons with IO-Link communication display takt time within workers' sightlines so that the assembly pace stays on track and meets production goals.

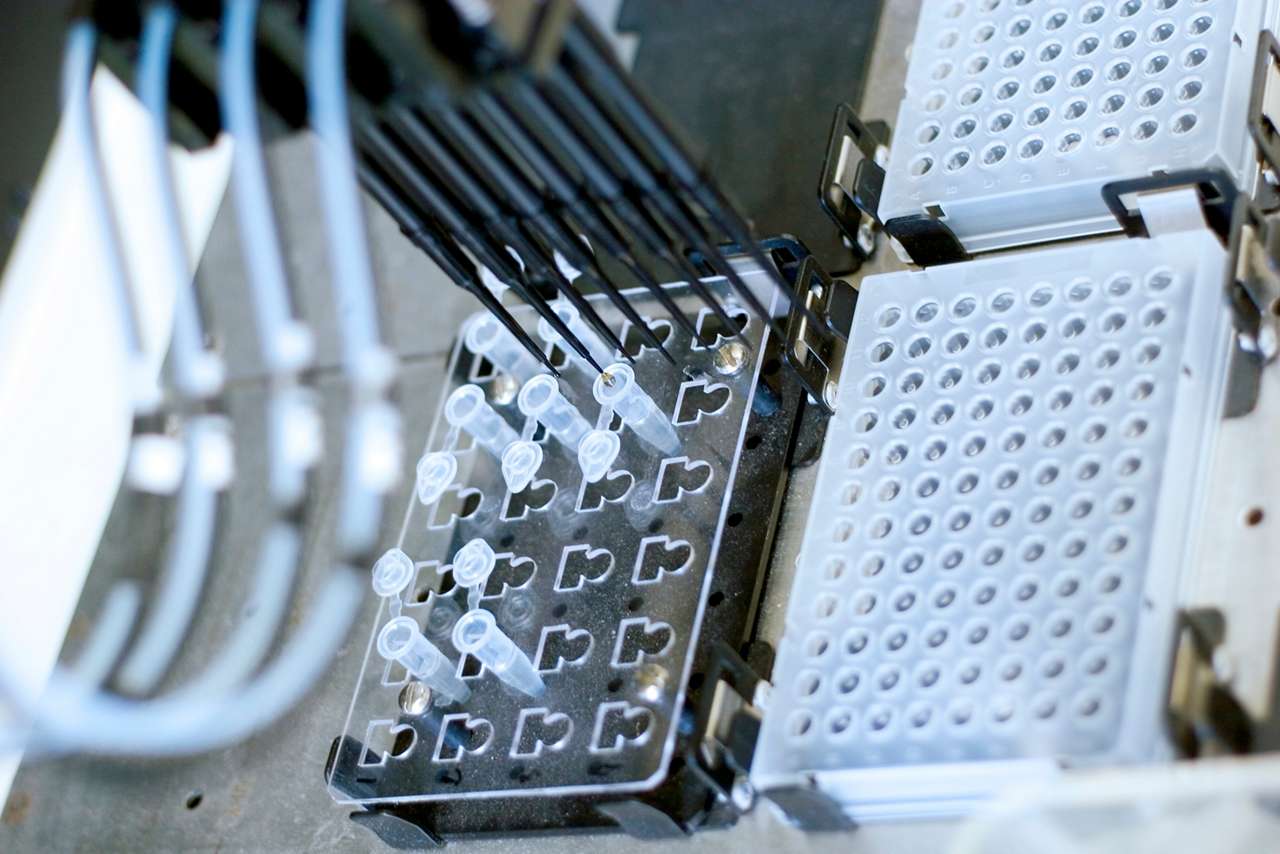

Clinical labs need to process samples quickly to keep throughput high and any lag during testing procedures would disrupt workflow. LED lightings, such as the K50L2, works as machine status indication so that the lab operators can process fix errors, handle samples, and collect results in a timely manner.

![Accurately Measuring Bakery Ingredients [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Baking is a mixture of creativity, precision and attention to detail. The Wilkinson Baking Company has added technical innovation to the mix. The Wilkinson Bread Bakery is a compact, completely self-contained and fully automated bread bakery. This unique machine combines technology with tradition to transform simple raw ingredients into bakery fresh bread at 40 loaves an hour.

![Status Indication on Driverless Vehicles [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

The K50L domed 50 mm indicator light works well for status indication on autonomous shuttle buses. The buses operate on short distances in outdoor environments that exposed the bus technology to a variety of weather conditions. The rugged K50L indicators are rated IP67 and IP69K to withstand water ingress in the harsh environment.

A leading machine manufacturer builds workstations designed for accurate, timely and cost-effective battery cell assembly. A value added component of the workstations is an operator guidance device that does three jobs: enables assembly processes to start and stop, indicates parts to be picked and installed, and completely stops line operation if emergencies occur. When it became too costly for the OEM to construct and mount these devices themselves, they turned to Banner to craft an all-inclusive solution. To honor the time line requirements of their customer—a major tier two battery supplier—the OEM needed the solution in eight weeks.

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

![繁忙製造地點中的通訊 [成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/K50-Touch-and-TL50---Industrial-Oven_For-Andrew.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

隨著更多的組件通過烤箱,與待卸載物品的流動保持同步變得越來越困難。分揀區逐漸變得擁堵。物品容易被引導至錯誤方向或甚至損壞。零部件流動的暫停使得卸貨操作人員可以糾正錯誤並令取貨站保持通暢。不過,卸貨和裝貨區之間的距離以及周圍機器的環境干擾使操作人員之間的通訊變得複雜。

為通道中的每個生產操作人員配備了一個無線節點和一盞K50 EZ-LIGHT燈。在每個堆高機上再安裝一個節點和一盞EZ-LIGHT燈。在生產操作人員需要耗材時,該操作人員按下EZ-LIGHT上的按鈕,將燈從綠色轉成紅色。同時,堆高機駕駛員的燈從綠色變為紅色,表示操作人員需要零部件。

EZ-LIGHT Daylight Visible可見指示燈產生高亮度光線,18個LED可以一起觸發或以每組6個、共計3組的形式來控制光強度,這使其非常適合需要在戶外環境中需要清楚通訊的應用。可選的遮陽板增加了它們的可見度,使其在具有高亮度陽光的環境中也同樣有效。

Sensor solutions to detect translucent bottles filled with clear liquid with a long bottling line with numerous areas to monitor.

視覺指示是溝通目前狀態的一種簡單有效方式,可保持設備高效運行,並提高生產力。信標燈在白天也高度可見,可顯示吊具扭鎖與操作人員機艙之間目前的狀態,以確保安全升降。信標燈有強烈的光輸出量,非常堅固耐用,很適合戶外指示應用。

當的窗戶直接位於電控箱後面時,LED指示燈必需非常明亮、持久的可全天提供高可視性的指示。Banner的EZ-LIGHT K50 信標燈適用於許多指示狀態應用,特別是在這個電控箱中的指示狀態,因為即使在白天信標燈也具有高可視性,並且其使用的節能LED非常持久、耐用。

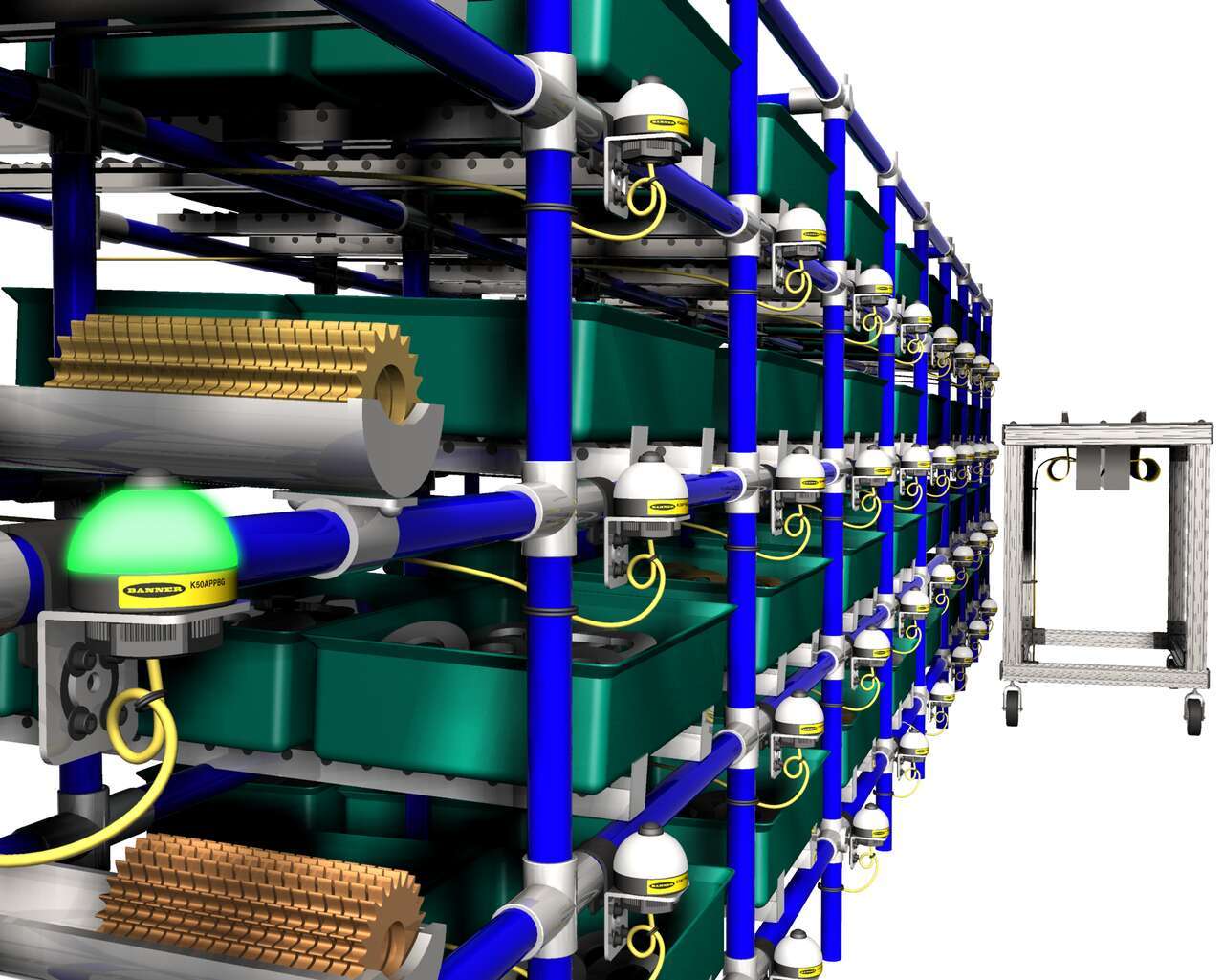

A Banner wireless solution is a simple way to optimize inventory, reduce errors, and minimize waste. Each SureCross Performance Node with I/O Mapping can be equipped with up to six EZ-LIGHT operator indicator lights. The SureCross Gateway is conveniently located at a central location where maintenance personnel and management can monitor the parts consumption throughout the site.

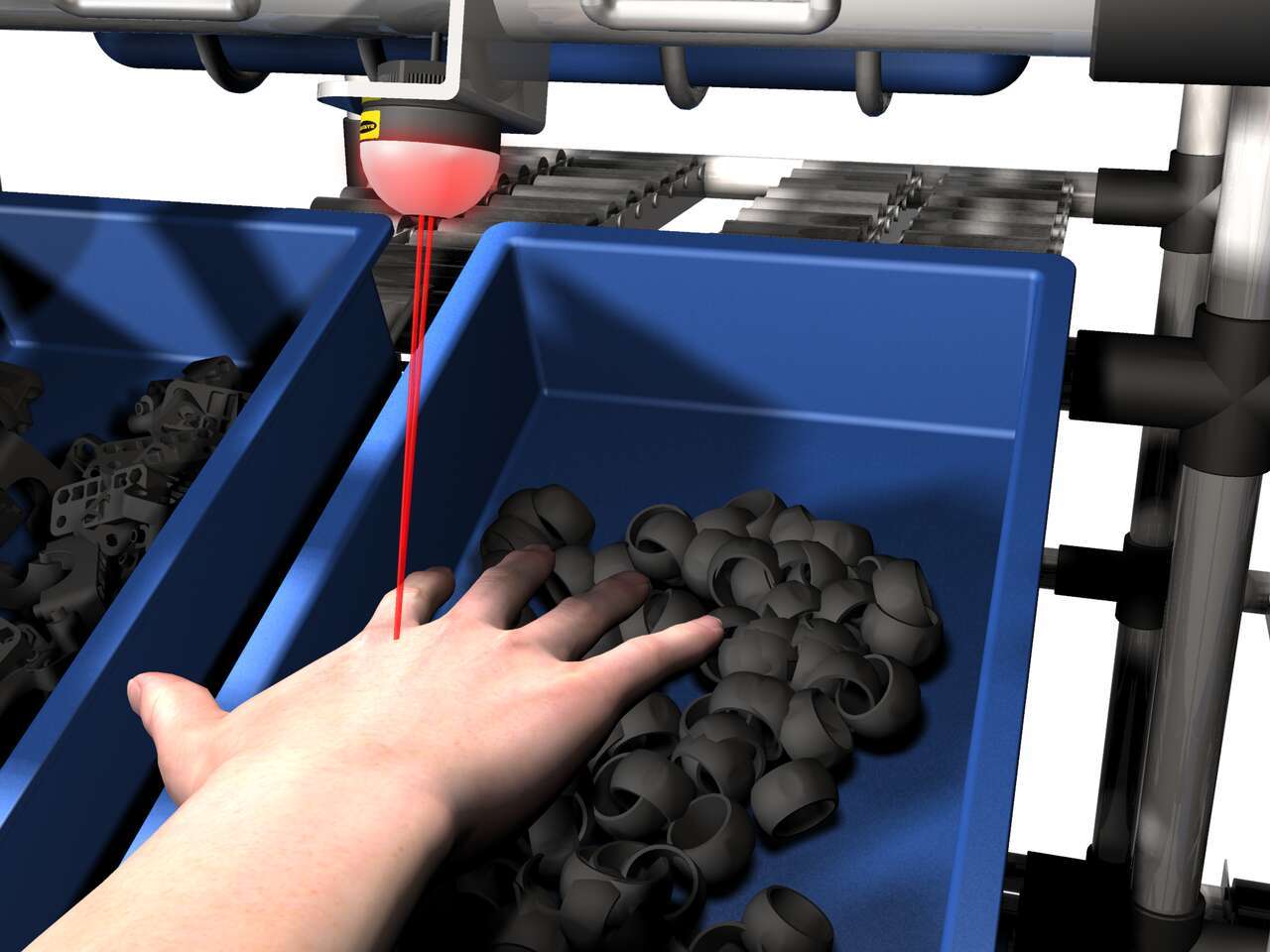

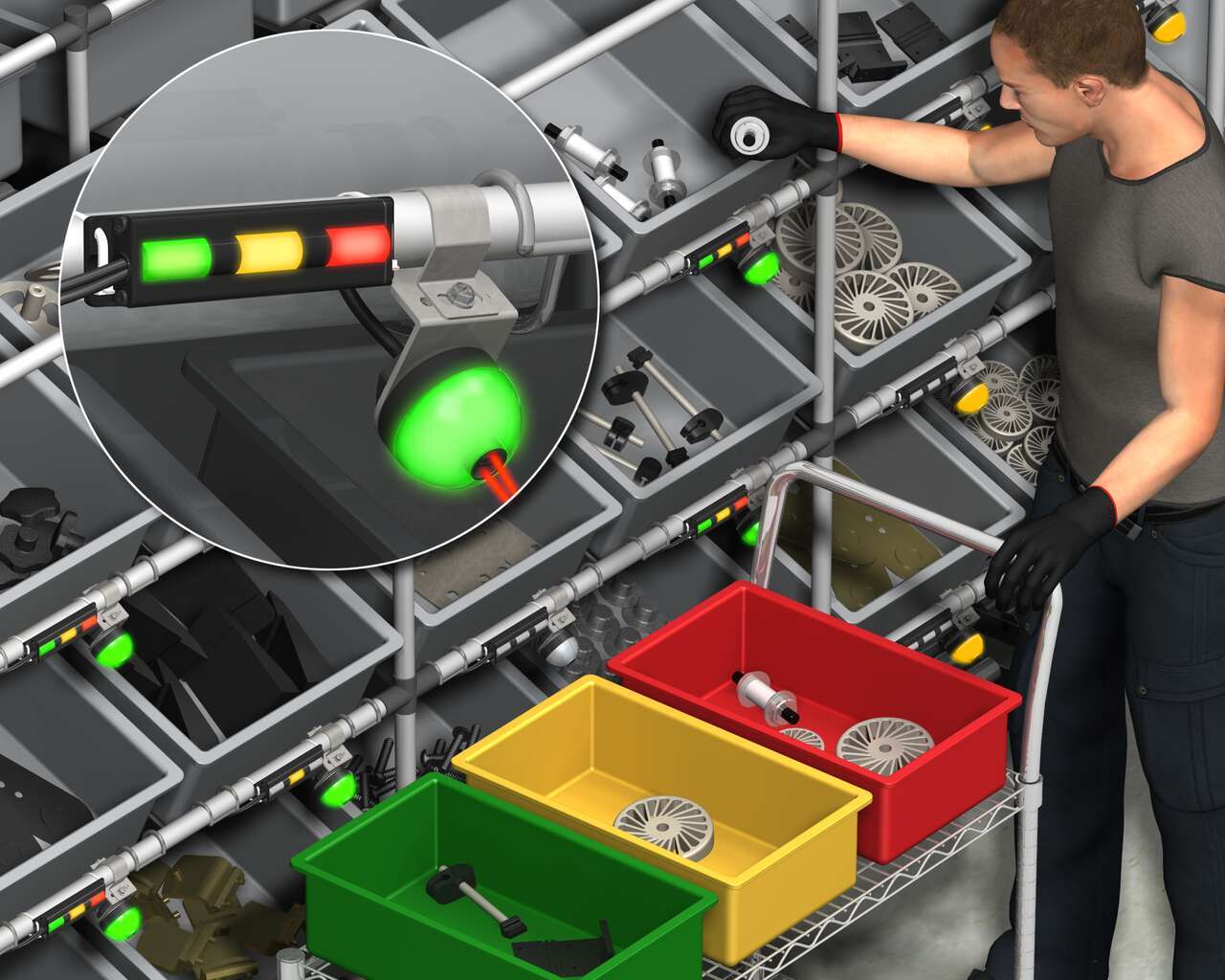

Banner’s K50 Series of single-point pick-to-light sensors are a simple, easy-to-use error-proofing solution in assembly applications. In this application, the job light is Green while the job input is active, indicating the correct bin for the next pick. The presence of the assembler’s hand initiates an output change of state, turning the job light red. The job light above the next pick location will then turn Green.

反射板式模式中EZ-LIGHT K50的感測器指示燈,按照裝配順序,下一個要取料的零件是天窗。當操作人員從寬口料箱中選擇天窗時,K50偵測到有人挑選了該項選擇。

Banner’s K50 Optical Pick-to-Light series is a compact, self-contained, three color indicator with integral sensor. Green typically indicates which part to pick, and when the internal sensor detects the hand, the indicator changes to yellow to confirm the task is complete. An optional third message is to display red for a mispick.

The EZ-LIGHT K50 sensor lights above a bin to show the assembler which part to pick. If the assembler reaches into a different bin, that bin's EZ-LIGHT K50 sensor lights up in the designated warning color—in this example, red— to indicate the error.

在糖果分銷商的訂單撿貨流程中, 配備EZ-LIGHT K50感測指示燈的箱子連接到根據訂單編寫程式的製程控制器。根據訂單要求,K50會亮起來,顯示有待選擇的物品。當工作人員將手放入箱子中時,指示器會偵測到手的存在,然後控制器就會觸發下一個待拾取糖果箱上的K50發光。

位於零件架上的按鈕EZ-LIGHT K50拾取燈感測器亮起,就是在指示要拾取的零件。拾取零件後,工作人員就按下指示燈上的按鈕,確認已經完成零件拾取。

Several technologies and solutions are available for bin-picking applications for error-proofing processes. Light arrays prompt the operator for part selection with integral job lights, then reliably sense retrieval of the part, using an array of visible red or infrared sensing beams located in front of the bin.

為了正確識別和使用視覺管理,當包已滿時感測器被觸發,然後將訊號發送到K50觸控按鈕以點亮紅燈,表示一個已裝滿的料籃。K50觸摸可以直觀地向操作人員需要剔除的袋子并利用一個空袋來代替剔除的袋子。為了顯示袋子已經為更多的包裝做好準備,操作人員按下符合人體工程學的K50按鈕,將其更換回綠燈,以顯示袋子已為後續包裝做好準備。

使用一體式機箱的緊急停止按鈕與K50 Touch指示燈組合,在緊急情況下可以傳達簡單的狀態指示。Banner的30 mm底座緊急停止按鈕有一個照明式基座,在啟動時基座從黃色變成閃爍的紅色,以清楚顯示緊急停止狀態。K50 Touch是一款符合人體工程學設計的自動化產品,不需要任何物理壓力即可操作,並且可以用空手或工作手套輕鬆啟動。

Banner的定距式K50指示燈檢測戴有手套的手,用來辨別操作人員在組裝過程中是否選擇了正確的零組件。之後,K50指示燈的邏輯功能可以透過從綠色更改為黃色(也可以選擇其他顏色,以配合製造商的選擇偏好)來通知操作人員其已經正確拾取。K50檢測深色手套的能力對於精益製造過程尤其重要,在此過程中,員工通常配戴深色手套。

Banner 多段式含蜂鳴器TL50在一體式裝置中使用高品質的多色LED燈,結合K50 Touch和PM8無線訊號傳輸系統,有效為零組件流程備料提供方案。首先,Banner的K50符合人體工學的觸控按鈕安裝在中控站,根據對應的PML8 Wireless Nodes節點進行編號準備,此節點和一個含音效的塔燈一起安裝在其他個別的工作站中。

The unique indication of the programmable K50 Pro touch buttons and Pro Editor software allows for versatile indication of numerous machine statuses and in-field customization. Multicolor and animation allow for quick identification of errors in work cells.

With a SureCross Wireless Network, FlexPower Nodes are deployed at each tank without the need to run cables for power or I/O data transmission. Banner’s unique power management capability enables a Node equipped with an ultrasonic analog level sensor to operate for years on a single DX81 battery power supply. A DX80 FlexPower Node offers a combination of discrete and analog I/O in a single package, eliminating the need for time-consuming manual data collection.

在強力的沖洗環境下,提醒操作人員在食品加工生產線上的秤重站上故障狀態。

A system of Banner’s TL70 wireless modular tower lights and K50 touch buttons provides an efficient, easy way to communicate a call for more parts with a forklift driver. When a workstation is almost out of cartons, the operator touches the ergonomic K50 touch button which changes the status on the connected TL70 wireless tower light to red.

一家紙板商品印刷廠無法對照標準生產率追踪機器操作人員的效率和表現。

當零部件供應量很低時,組裝人員將EZ-LIGHT K50按鈕向左推(該按鈕用作呼叫按鈕),向滑道發出提供更多零部件的訊號。右側的K50燈用作零部件拾取指示燈。

在安裝EZ-LIGHT K50L指示燈之前,操作人員在機器上放置零組件,會先離開工作區域,檢查堆疊燈以查看是否正確裝載了該零組件。如果沒有,操作人員必須在啟動機器對零部件的加工之前重新設置和檢查過程。由於K50L安裝在工作站內,使用簡單的Y接頭,操作人員可以立即知道零組件是否正確放置。

感測器解決方案,為洗車區內提供明亮指示,傳達洗車週期各階段的狀況。

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Watch this video for an overview of the features and benefits of the K50 Programmable Touch Button.

Watch this video for an overview of the features and benefits of the K50 Programmable Touchless Button.

Watch this video for an overview of the features and benefits of the K50 Programmable Indicator.

Watch this video to learn about the K50 Pro Select Touch Button 3-State Mode.

Watch this video to learn about the K50 Pro Select Optical Touch Button 4-State Detection Mode.

Watch this video to learn how to use the Pulse Control feature of the K50 Pro Select Indicators.

Watch this brief how-to video to see how Banner’s Pro ID feature and Pro Editor software quickly and easily copy configurations to Pro Select lighting products.

This video covers the basics of programing the audible alarm available in select models of the K50 Pro Touch Button from Banner Engineering.

This video covers the basics of the 4-state mode for the K50 Pro Touch Buttons from Banner Engineering.

This video covers the basics of the 3-state mode for the K50 Pro Touch Button from Banner Engineering.

The Pro Series programmable multicolor LED devices from Banner Engineering offer limitless possibilities for advanced indication of dynamic machine states, operator interaction, and process statuses. Watch the video to see what elevates a Banner Pro light above a traditional factory light.

Banner Engineering offers a complete portfolio of touch buttons for your simplest to most advanced touch requirements. Watch the video to learn more about our capabilities for touch and indication.

![RGB Indicators for the Visual Factory [Video]](/content/dam/banner-engineering/projects/video-thumbnails/indication_for_the_visual_factory-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Indicator lights are the visual language of machines. However, traditional indicators are limited. Watch the video the see how programmable RGB indication clarifies communication, simplifies your supply chain, and allows you to quickly create custom indication to match your process.

![K30, K50 and K70 Gen 2 Touch Buttons [Video]](/content/dam/banner-engineering/projects/video-thumbnails/K30_K50_K70_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

即使安裝在最嚴苛以及髒亂的應用環境之中,Gen2 拾取指示燈也能夠精準而持續的回應您的動作耐化學腐蝕的聚碳酸酯外殼,即使安裝在化學物質噴濺的環境也不會受到影響。

![K50 Pro and K30 Pro: Bolder Indication for Everyone, Anywhere [Video]](/content/dam/banner-engineering/projects/video-thumbnails/K30_And_K50_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Banner Engineering第二代的K50以及K30多功能指示燈,提供您更多指示燈選擇,簡化的配線以及更少的庫存需求,有效提升營運管理效率。有七種顏色的燈光可以選擇,放在單一的堅固耐用指示燈中.

Learn how to use the Pro Editor to configure K50 Pro Touch buttons.

This video covers the basics of setting up a K50 Pro Series Indicator from Banner Engineering.

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.