LE Series

1 m Range Laser Displacement Sensor

The LE series linear array technology provides great performance and resolution regardless of detection objects color or sheen.

- Ready to measure right out of the box

- Easy adjustment with a two-line, eight-character intuitive display

- Linear array provides repeatability and accuracy for challenging targets

- Visible laser for small spot size and easy alignment

- Models with IO-Link available

Downloads

技術文獻

產品資料檔案

PLC 支援文件

軟體

手冊和目錄

Application Notes

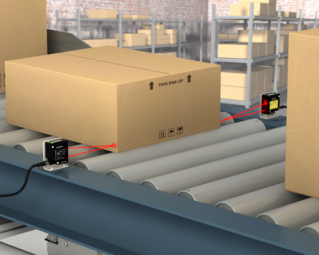

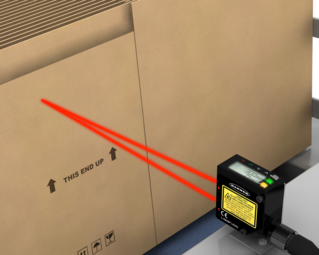

紙盒外形尺寸確定

在輸送帶上移動的紙盒行經兩個LE550雷射感測器,測量紙盒寬度以便正確分揀。LE550感測器是確定紙盒外形尺寸的經濟型解決方案。類比輸出向PLC發送信號,以將紙盒交付到正確的儲存位置。Banner的LE550在測量紙盒的高度、長度和寬度時提供重複性和精準度。雷射感測器具有直觀的使用者介面,便於調整設定。

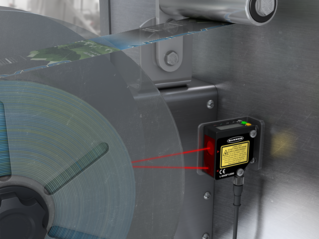

Sheet Metal Roll Diameter

Banner’s LE550 provides repeatability and accuracy across challenging targets, including shiny, reflective surfaces like metal. The laser sensor has an intuitive user interface, making it easy to adjust settings and set up a roll diameter application, without needing to unwind the metal roll. The analog output can be used to control wind or unwind speeds.

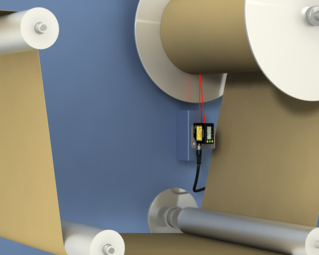

Roll Diameter Measurement of Dark Material

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allowing for reliable measurement of the dark blue material.

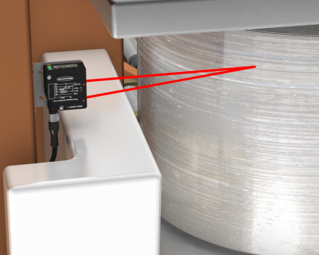

量測塑膠捲直徑

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allows for reliable measurement of the shrink wrap.

Laser Sensors Measure Paper Rolls in a Range of Colors & Automatically Scale Output

After a convincing demonstration, the company chose Banner’s L-GAGE® LE550 laser gauging sensors to replace the ultrasonic sensors on their winders. Like the optical sensors, the LE550 is unaffected by drafts in the facility. Unlike the optical sensors, the LE550 is color insensitive. Linear array technology enables the LE550 to measure each roll, regardless of paper color, even colors that had most challenged the optical sensors.

Roll Diameter on Labels

In the beverage industry, labels need to be applied to the bottles quickly and without error to keep production levels high. Accurately monitoring the thickness on a spool of labels and controlling the unwinding speed is very important for the process to run smoothly. A solution is needed that can accurately supervise and report the material levels on a spool in order to prevent it from running out during the manufacturing process and delaying production.

Case Stacker Inventory and Presence Detection

The two point teach option on the analog setting can be used teach the front of the flat cases as the 20 mA point and can easily be adjusted for a manual set of the 4 mA to the end of the cases. This helps gauge how many flat cases are left, so more cases can be added when the case count is getting low. The digital output can also be used for presence detection. This helps ensure there is a case available to be picked up, and also ensures only one box is picked up at a time.

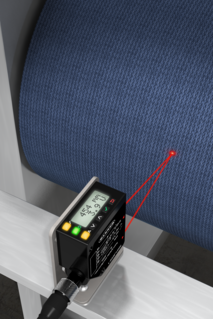

Sensors to Measure Movement Range

During assembly, inspections are conducted to measure seat height adjustment, forward and rearward movement, and upright and recline motion. Two sensors are used for each inspection. The sensors are deployed off the conveyor line to ensure easy access to and the free movement of the seats. At its maximum range during inspection, a seat may be as far as a meter away from the sensors.

![Inspecting Small Connectors [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Inspecting Small Connectors [Success Story]

An automotive supply company makes a range of vehicle systems. Their seating systems combine structure and design with features that enhance comfort and safety. Weight sensors installed on the underside of the seats work in coordination with vehicle safety systems to determine the size and position of a seat occupant. These factors affect how or if airbags will be deployed in the event of an accident.

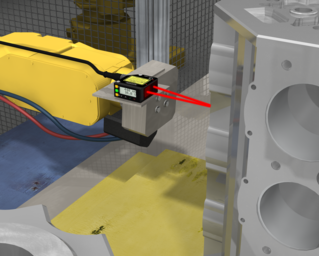

引擎氣缸零部件就位偵測

Banner的LE550雷射感測器是零部件就位驗證過程的理想選擇。它很可靠,並且對於長距離的小型零部件就位驗證非常準確。LE550採用數位輸出來測量3 mm厚度,確保固定夾存在並且引擎氣缸位於正確的位置。

High Speed Package Profiling with Laser Sensors

A laser measurement solution enables high-speed package sorting in order fulfillment applications and helps drives failure rates down—ultimately saving costs and maximizing profits.

Videos

![LE550 Laser Measurement Sensor [Video]](/content/dam/banner-engineering/video/video-thumbnails/products/LE550%20Product%20Thumbnail.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

LE550 Laser Measurement Sensor [Video]

正確應用和安裝是重要關鍵。每個產品在BannerEngineering.com上均可查看包裝說明和線上手冊,請務必仔細閱讀並遵守。