Sheet Metal Roll Diameter

Challenge

In the metal stamping industry, it is important to accurately determine the diameter of a roll of sheet metal to prevent the material from running out. It can be challenging to find a sensor that accurately measures the thickness of the roll on a shiny metal surface.

Solution

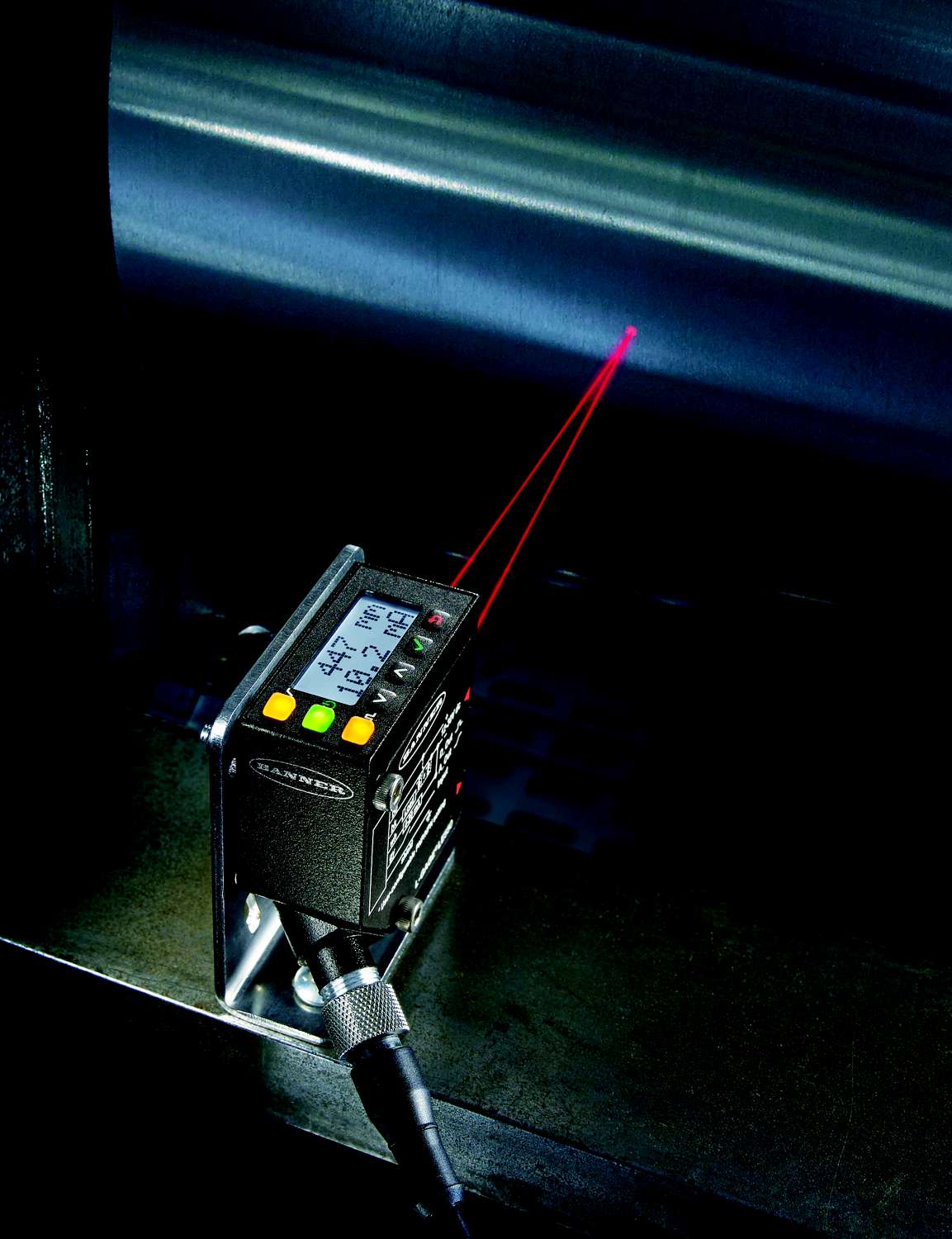

Banner’s LE550 provides repeatability and accuracy across challenging targets, including shiny, reflective surfaces like metal. The laser sensor has an intuitive user interface, making it easy to adjust settings and set up a roll diameter application, without needing to unwind the metal roll.

The analog output can be used to control wind or unwind speeds. The two point teach option can be used teach the outside of the roll as the 20 mA point and can easily be adjusted for a manual set of the 4 mA point to the core diameter.

The discrete output can also be utilized for a roll diameter application. It can alert operators that the roll is almost empty. The setup is simple using a single switch point. Similar to the manual adjust on the analog output, the user would adjust the feature to set a limit near the diameter of an empty core.