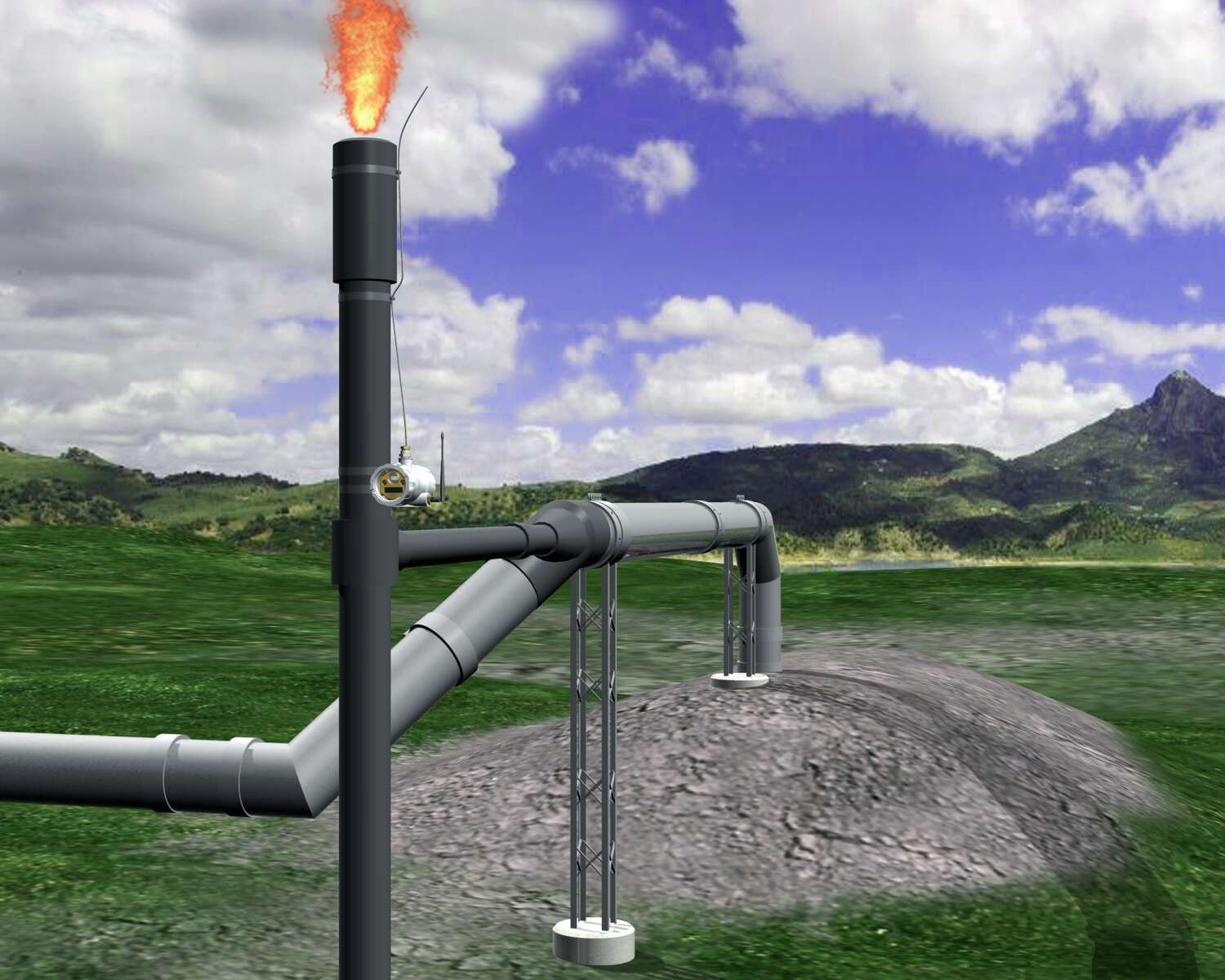

垃圾掩埋場甲烷收回和燃燒塔監測

應用挑戰

為符合政府規定,垃圾掩埋場管理人員需要準確監測沼氣的產生、移除、排放和燃燒。

有效測量和蒐集資料的能力不僅是資源管理的問題,也是對地方、州和聯邦組織規定的遵守和盡責問題。

若知道燃燒塔中甲烷流量和溫度,就可定義甲烷何時被排放到大氣中。

因釋放甲烷可能違反經營許可證規定,業者將來可能會遭到罰款或強制購買「碳信用額度」。

解決方案

為了準確判定甲烷生產水平和流量,可用壓力感測器偵測甲烷生產系統中存在的壓力和真空狀態。

連接到FlexPower Nodes的熱電偶用於精確偵測活性火焰的熱量,以檢驗甲烷的燃燒是否處於持續狀態。從邏輯上看,如果儀表顯示燃燒塔有甲烷流量和溫度,則操作人員就符合規定。如果儀表顯示螢幕甲烷流量和溫度都低,操作人員就不符合規定。

連接到壓力感測器和溫度感測器的FlexPower Nodes會蒐集資料,並將資料無線傳輸回GatewayPro或主機系統,進行記錄和分析,以符合當地、州和聯邦法規的規定。

對於困難的拓撲結構,SureCross資料無線電可通過障礙物傳輸資料,並擴展DX80感測器網路的範圍。

特色產品

Performance Series Industrial Wireless Gateways and Nodes

建立一點對多點無線網路,以在大區域上分配I/O。輸入和輸出類型包括數位訊號(幹觸點,PNP/NPN)、類比(0至10 V直流,0至20 mA)、溫度(熱電偶和RTD)以及脈衝計數器。

Remote I/O

Remote I/O products optimize control system performance and simplify system design for machine builders and controls engineers.

Technologies

Choose from a wide selection of product technologies to enhance your new or existing system with advanced capabilities. Whether it be our programmable multicolor LED devices with Pro Editor Software, flexible pick-to-light systems with PICK-IQ™, or exclusive safety devices with In-Series Diagnostics, Banner Engineering can help customize your ideal solution to address even the most complex applications.

Remote I/O

Remote I/O products optimize control system performance and simplify system design for machine builders and controls engineers.

Technologies

Choose from a wide selection of product technologies to enhance your new or existing system with advanced capabilities. Whether it be our programmable multicolor LED devices with Pro Editor Software, flexible pick-to-light systems with PICK-IQ™, or exclusive safety devices with In-Series Diagnostics, Banner Engineering can help customize your ideal solution to address even the most complex applications.

Remote I/O

Remote I/O products optimize control system performance and simplify system design for machine builders and controls engineers.

Technologies

Choose from a wide selection of product technologies to enhance your new or existing system with advanced capabilities. Whether it be our programmable multicolor LED devices with Pro Editor Software, flexible pick-to-light systems with PICK-IQ™, or exclusive safety devices with In-Series Diagnostics, Banner Engineering can help customize your ideal solution to address even the most complex applications.