Sensor Miniatura da Série Q2X

Sensor Fotoelétrico Compacto

O Q2X é a próxima geração de sensores fotoelétricos miniatura. Com o seu tamanho compacto e design robusto, o Q2X é ideal para instalação em máquinas muito precisas e espaços industriais reduzidos.

- Sensor em miniatura para instalação nos menores espaços

- Detecção precisa e confiável de posição de pequenos componentes

- Flexibilidade de projeto da máquina com opções comprovadas de montagem e conexão

- LED vermelho pequeno de alta visibilidade ou emissor laser Classe 1 (apenas modelo de campo ajustável)

- Maior imunidade a luzes energeticamente eficientes

- Algoritmo de imunidade à interferência permite que dois sensores sejam usados próximos um do outro

Downloads

Literatura Técnica

Arquivo de Dados do Produto

Arquivos de suporte PLC

Literatura de Marketing

Application Notes

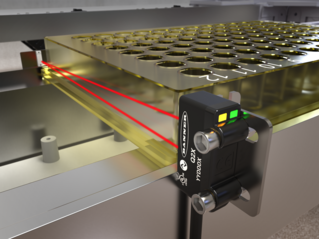

Reduce False Jam Detections

The Q2X Series Miniature Sensor is used on packaging conveyors to avoid jams.

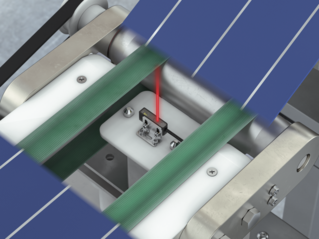

Accurate Positioning in Medical & Scientific Laboratories

The miniature Q2X LPF is a polarized retroreflective sensor small enough to fit inside many types of machines that cannot accommodate larger sensors.

Dark Wafer Presence Detection

Adjustable-field Q2X sensors use high excess gain to detect the presence of dark wafers on conveyors.

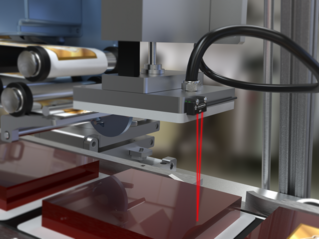

Streamline Labeling Process with a Fixed-Field Sensor

A miniature Q2X fixed-field sensor can be fitted onto the labeling machine’s tamp head to sense targets at a fixed distance.

Videos

How-To Guide for Q2X Laser Measurement Sensor with Push Button

This short video covers the basics of programming the Q2X Laser Measurement Sensor from Banner Engineering.

Choosing A Banner Photoelectric Sensor

This video guides you through the key features of our sensors and helps determine which sensor within our photoelectric portfolio is best for a specific application.

Choose Your Q2X Series Miniature Sensors

An overview of the different types of Q2X Series Miniature Sensors.

How-To Guide for Q2X Laser Measurement Sensor with Push Button

This short video covers the basics of programming the Q2X Laser Measurement Sensor from Banner Engineering.