Remote Monitoring of Edge Devices

What is Remote Monitoring?

Collecting and analyzing data from sensors and other field devices, remote monitoring provides factories with insight and visibility into the performance of their machines, processes, and people. Even sensor data can be accessed in real time from any location, as well as logged for long term analysis.

Keep reading to learn about how remote monitoring technologies are revolutionizing industrial automation, offering smart factories greater visibility into their operations, and enabling better, data-driven decisions.

Wireless sensor networks provide remote monitoring capabilities and allow manufacturers to increase overall process efficiency and productivity.

By eliminating the wire limitations of conventional systems, wireless networking systems improve data logging, process monitoring and control, while maintaining high levels of security and integrity. Wireless sensor networks are especially advantageous where wired solutions are impractical, ineffective, or cost-prohibitive.

While historically wireless systems were difficult to install and complicated to maintain over time, wireless technology has advanced significantly over the years. Today many remote monitoring solutions are available that offer a reliable wireless communication integrated into a single, inexpensive unit. These new wireless I/O devices are easy to install, and then uninstall and move to a new location as monitoring requirements change.

Predict Failures and Prevent Unplanned Downtime

Remotely monitoring conditions like changes temperature and vibration enables predictive maintenance for machines. The benefits of predictive maintenance include:

- Avoiding machine failures by making maintenance decisions based on historical and real-time data from the machine itself.

- Enabling quick intervention to avoid downtime by monitoring time-sensitive conditions like changes in vibration, temperature, humidity, or tank level.

- Initiating real-time alerts to operators so that critical situations can be resolved quickly to avoid extended downtime, scrapped materials, or product recall.

Track and Reduce Causes of Waste

Remote monitoring provides a variety of benefits for facilities seeking to improve the overall efficiency of their operations. For example:

- Remote monitoring technologies provide data for OEE calculations.

- Facilities can reduce waste and minimize its impact thanks to visibility into when and where inefficiencies occur.

- Access to logged data from sensors and indicator lights on machines enables users to track performance trends over time and identify steps for improvement.

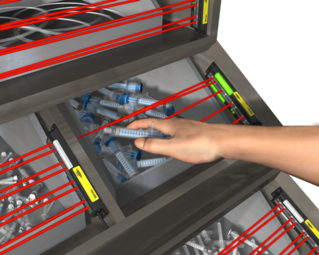

Streamline Call for Parts, Pickup, and More

Remote monitoring technologies are also capable of improving the efficiency of manual assembly and production lines. Some of the benefits of wireless factory notification systems include:

- Allowing managers to remotely monitor multiple lines and work more efficiently by reducing the amount of time spent checking in on lines unnecessarily. This enables managers to quickly respond to issues as they arise and focus their attention where it's needed most.

- Increasing efficiency when managing and responding to call for parts, service, or pickup.

- Reducing the need for workers to leave their workstations and find a manager when they need assistance.

Wireless Controller for IIoT Applications

Os controladores sem fio industriais da Série DXM são projetados para facilitar a conectividade Ethernet e as aplicações da Internet Industrial das Coisas (IIoT).

- Rádios ISM disponível em 2,4 GHz para rede sem fio local

- Converte Modbus RTU em Modbus TCP/IP ou Ethernet I/P

- O controlador lógico pode ser programado usando regras de ação e métodos de linguagem de texto

- Cartão Micro SD para registro de dados

- Alertas por e-mail e texto

- Modem de celular para conectividade por celular

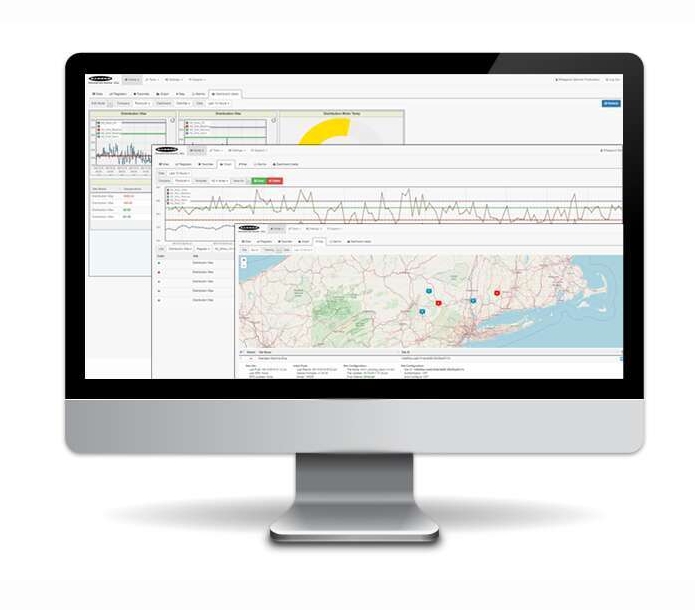

Software for IIoT Applications

O software Connected Data Solutions (CDS) é uma plataforma baseada na Web que permite aos usuários acessar, armazenar, proteger e exportar dados críticos coletados pelos sensores com fio e sem fio da Banner. O software complementa o nosso portfólio de produtos sem fio e fornece aos clientes soluções completas de IIoT end-to-end para resolver os problemas mais urgentes dos mercados industriais.

- Com ferramentas de análise e visualização, o software oferece insights que permitem que você resolva desafios reais no chão de fábrica.

- Armazene dados e analise tendências ao longo do tempo

- Acesse remotamente os dados a qualquer momento e em qualquer lugar usando um dispositivo conectado à Internet.

- Receba notificações em tempo real via e-mail ou mensagem SMS.

Vibration and Temperature Sensor

QM30VT Series sensors have a low-profile design and rigid metal construction that reduces resonant interference and increases surface contact, enabling exceptional levels of accuracy in measuring RMS velocity and temperature. They are able to detect even slight increases in machine vibration and temperature for early identification of potential problems.

- Communicates performance data using a MultiHop Modbus Radio or 1-Wire Serial Node to a DXM Series wireless controller or gateway

- Detects potential problems on motors, fans, pumps, and any machine with rotating motion or vibration

- Ultracompact design fits easily in small spaces

- Available in models with a 316L stainless steel housing or a heavy-duty aluminum housing

- Fully compatible with Connected Data Solutions software and the Wireless Solutions Kit for Vibration and Temperature