Kitting and Sequencing

Build Kits and Assemblies Quickly and Accurately

Kitting involves assembling separate but related items into a single unit or kit that is packaged together.

In Just In Time (JIT) manufacturing, sequencing refers to delivering kits of materials to the next station exactly when they are needed to ensure maximum efficiency.

For example, in automotive manufacturing, kits of parts are delivered to the next stage of production at exactly the time that a kit is needed. Assembling kits in this way is also known as "offline kitting."

Pick-to-light solutions help ensure kits are assembled accurately at a fast pace and can be delivered to the next stage of production at the right time.

Ensuring Quality in Kit Building is Essential

Kitting and sequencing applications can be challenging because kits and other assemblies are often made of many different components. Each kit must be assembled correctly to ensure that end users, or assemblers at the next stage of production, receive a complete kit.

Due to the number of items, and the variety of kits that may be assembled at a station, it can be easy for assemblers to lose track of what has already been put in the kit. For example, they may accidentally leave out items or add duplicate items, which increases costs and makes parts inventory management a challenge.

Manually verifying that each kit is complete, and does not contain duplicates, is time-consuming and prone to error. Therefore, it is necessary a solution that can streamline assembly tasks and verify accuracy.

Just In Time sequencing applications depend on a fast, accurate kit building to ensure that kits arrive at the next station at the right time and contain all of the necessary parts.

Ensure Quality Even in Large, Complex Assemblies

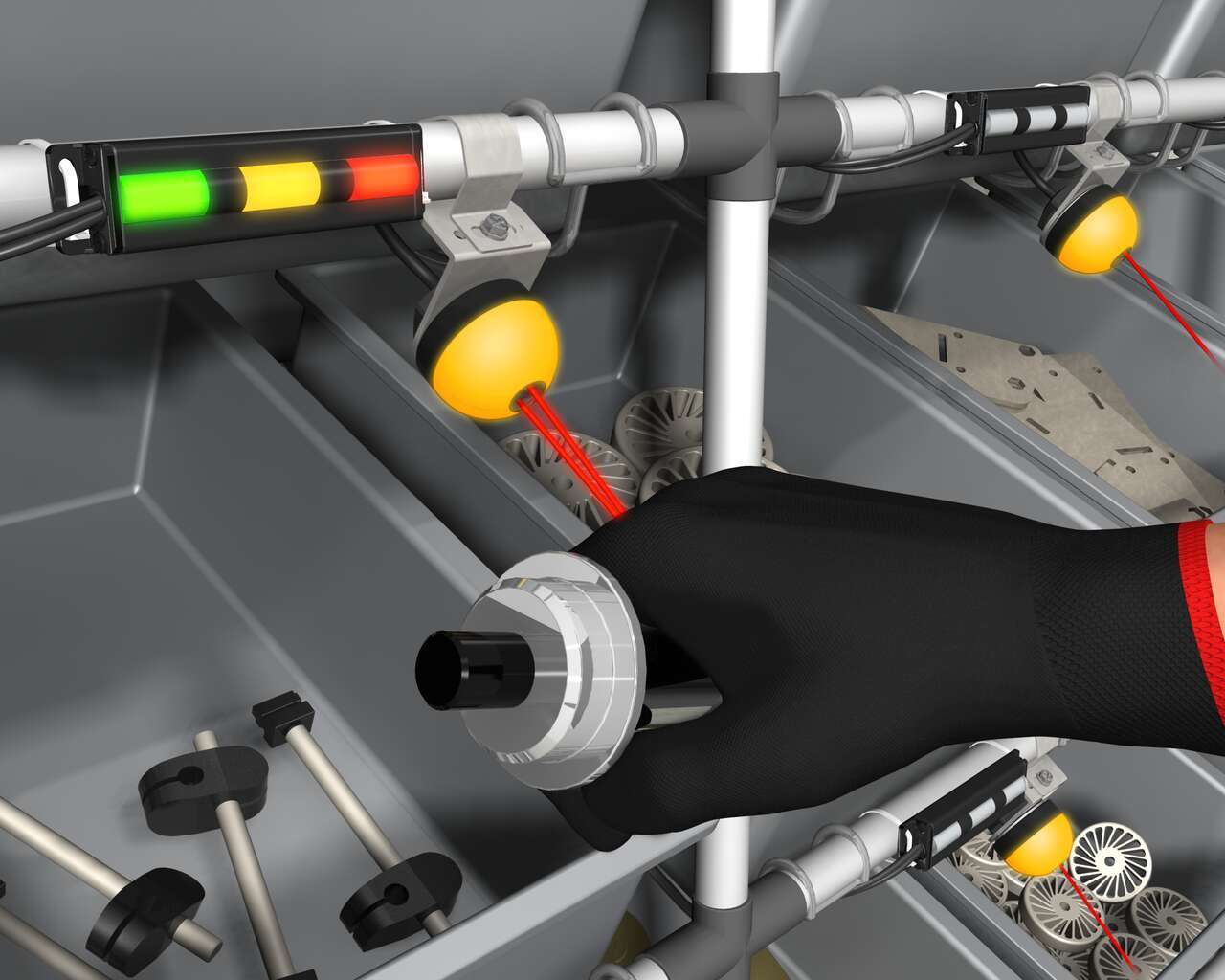

- At stations where multiple different kits are assembled, specific colors can be assigned for each kit. Pick-to-light devices illuminate with the corresponding color, such as blue, alerting the operator to pick items from all the bins with blue lights.

- Devices with an alphanumeric display indicate the quantity of each item to pick.

- After an operator has transferred the items from each pick bin to the color-matched kit bin, they press the blue touch button to signal that they are finished, and the light turns off.

- The process is repeated with additional colors, and once all the lights are off, that round of kit is complete.

Check Pick Accuracy in Real Time

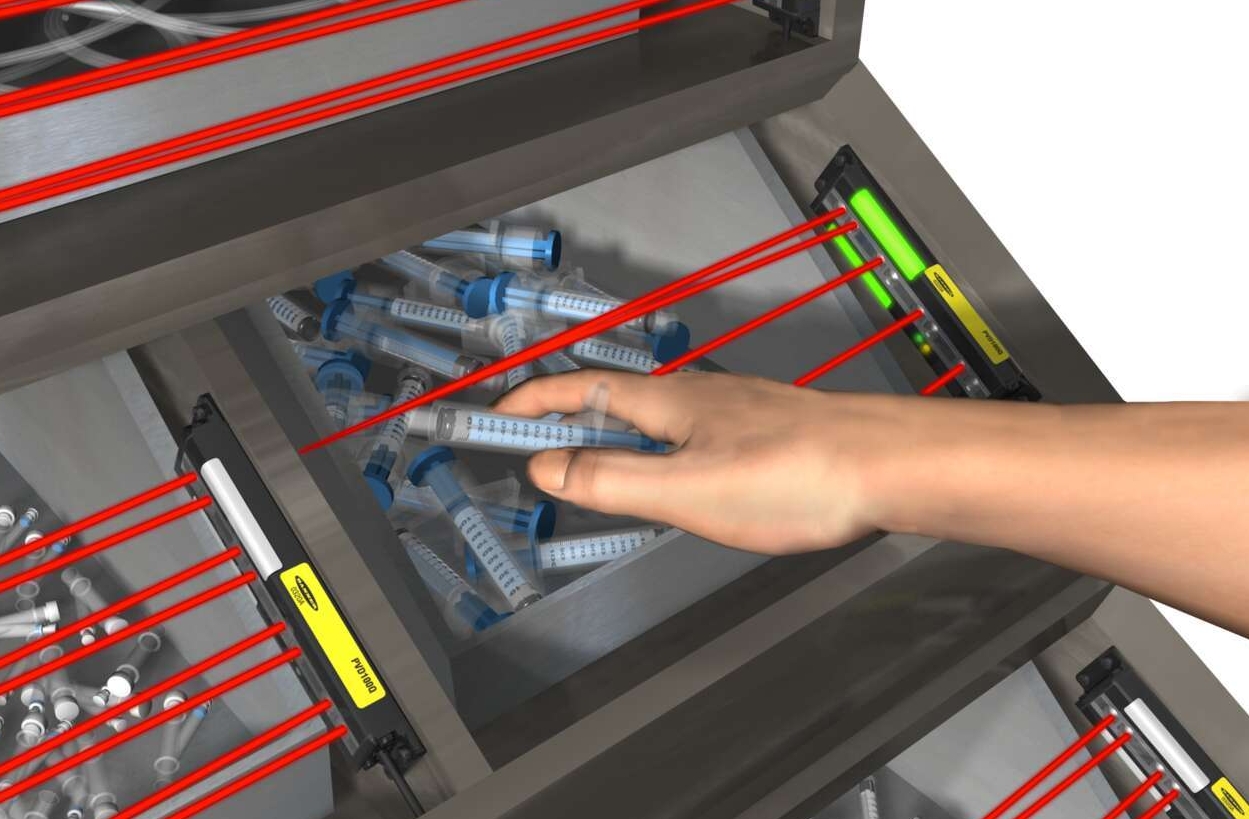

- Pick-to-light devices with optical sensing capabilities can be used to check picks for accuracy in real time.

- These devices detect when a hand reaches into a bin and breaks the sensing beam or array.

- When picks are executed correctly, yellow LEDs confirm that the operator picked from the right bin.

- If the operator reaches into the wrong bin (for example, to pick the wrong item or pick a piece out of order), a light turns red indicating an error.

Reduce Wasted Time and Save Costs

- Light-guided solutions speed up onboarding time for new employees, as well as training on new product assembly. Different colors of lights are easy to interpret quickly with minimal training.

- Pick-to-light solutions reduce time wasted re-reading instructions, as well as checking and re-checking work.

- By verifying parts at each step, pick-to-light solutions can reduce errors during the assembly process and save time during quality inspections downstream.

- Improving efficiency at both assembly and inspection stages reduces overhead costs and increases profitability.

Pick-to-Light Devices

A Série K50 Pro é uma família versátil que combina um indicador grande e brilhante com capacidade de comutação de estado sólido ativada com um simples toque. Ideal para operações lean manufacturing e de retirada de peças de compartimentos. Os botões touch K50 Pro combinam tecnologia touch comprovada e robustez com a versatilidade dos LEDs RGB. Os botões touch K50 Pro são compatíveis com o software Pro Editor para fácil personalização.

- Indicadores LED brilhantes combinados com recursos de comutação ativados por toque

- Os modelos compatíveis são programáveis usando o Software Pro Editor e o Cabo Conversor Pro da Banner para personalização de cores e animação

- Invólucro IP67 e IP69K resistente e totalmente protegido para ambientes de lavação de alta pressão

- O design ergonômico não requer nenhuma pressão física para operar, evitando o estresse nas mãos e nos pulsos

- Ideal para aplicações pick-to-light e de botão de chamada em uma ampla gama de indústrias e ambientes - de alimentos e bebidas ao automotivo

- Até quatorze variações de cores em um dispositivo (verde, vermelho, amarelo, azul, branco, ciano, magenta, laranja, âmbar, verde limão, verde primavera, azul celeste, violeta e rosa).

- Os modelos IO-Link possuem recursos Pro completos gerenciados dinamicamente pelo mestre, além de controle de LED individual para total personalização do status

Pick to Light Devices

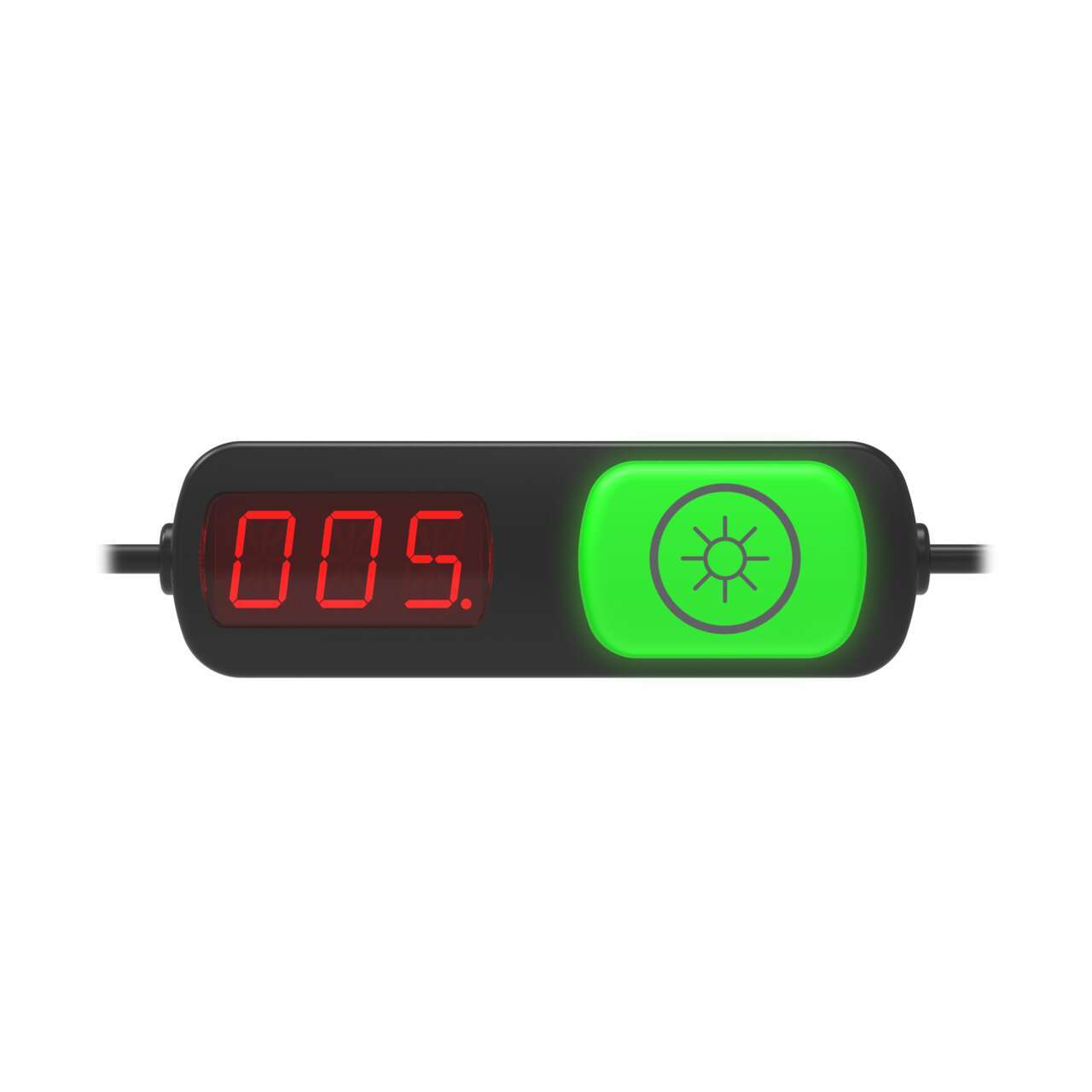

A smaller version of the K50 Series, the K30 Pick-to-Light Series combines a bright indicator light with solid-state, touch-activated switching.

- Ergonomic design requires no physical pressure to operate, preventing stress on hands and wrists

- Simple operation with the touch of a finger

- Easily actuated with bare hands or work gloves

- Rugged, fully encapsulated IP69K construction for high-pressure wash-down environments

- Ideal for pick-to-light and call button applications in a variety of industries

- 1- and 2-color models available to solve a range of application

![Operator Guidance Solution [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)