Light-Guided Kit Building at Large Station

Kit building can be a time-consuming process to complete. Pick-to-light solutions are often used to direct operators to specific pick points that are needed to complete a kit, however, large-scale stations present new challenges. Keep reading to learn how the scalable PTL110 devices can be used to improve extensive kitting.

Kitting on production lines or in fulfillment centers can be a slow process where the bins and storage racks become challenging to navigate, especially if different types of kits are being put together in the same area. Searching through stock in a warehouse to gather all the pieces needed causes an excessive amount of downtime and has a negative impact on productivity. Using versatile pick-to-light devices to create a guided kitting system is a simple and efficient way to streamline the process and ensure accuracy, saving companies time and money.

Light-guided kitting can prove to be very beneficial for companies but creating an organized picking system also presents new challenges. The PTL110 pick-to-light devices work to create a kitting station that encourages speed and keeps errors to a minimum.

In a large kitting station, there are multiple pick points with one operator grabbing the necessary items for each different kit. To simplify and speed up the process, one PTL110 is installed below each bin. Specific colors are assigned for each kit and the PTLs light up with the corresponding color, such as blue, alerting the operator to pick items from all the bins with blue touch buttons. The display indicates the quantity to pick. After the operator has transferred the items from each pick bin to the color-matched kit bin, they press the blue touch button to signal that they are finished, and the light turns off. The process is repeated with additional colors and once all the lights are off, that round of kitting is complete.

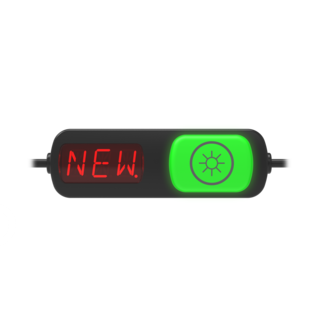

These versatile pick-to-light devices can be programmed to display alphanumeric characters and be used to indicate how many pieces need to be removed. Each touch button can also be as a dual-color indicator for additional programming flexibility when assembling multiple kits at once.

Kitting tends to move at a slower rate when a facility has many pick points. Fortunately, the PTL110s are powered by PICK-IQ™ to reduce the usual latency that results from polling multiple devices. The quick response speed makes the PTL110 an ideal solution for manufacturing and fulfillment stations that have numerous pick points because it will not slow down the kitting process. PTL110 pick-to-light devices are also scalable for large or expanding pick stations.

Flexible Pick Functionality

The PTL110 series is available with optical and touch sensor capabilities for versatility in solving diverse applications. They can be used together or individually to confirm pick actions plus secondary functions. The optional display can indicate part count or provide other instructions with alphanumeric characters. Users have full control of fourteen colors and multiple animation functions so the indicator can be used to differentiate multiple conditions.

Enhanced Serial Communication

PTL110 devices are powered with PICK-IQ, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that comes from polling multiple devices. The high response speed that results works well for applications that require many pick points while maintaining a rapid pace for productivity.