Error Proofing and Poka Yoke

Prevent Errors in Lean Manufacturing Environments

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line.

Another word for error proofing is poka-yoke (which is Japanese for avoiding inadvertent errors). Poka-yoke design is often used to avoid human error by either warning operators when they are about to make a mistake or preventing them from making a mistake at all. Poka-yoke design makes it virtually impossible for an operator to complete an action incorrectly.

Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

Quality Inspection at the Source

Error-proofing takes quality control to the next level by checking for mistakes and defects before those defects can proceed to the next stage of production. Preventing defects from proceeding from one stage of production to the next avoids wasted time and resources spent working on defective parts.

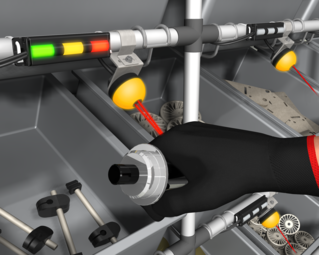

In manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

Meanwhile, in more automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Banner Engineering provides sensor, vision, and light-guided solutions for error proofing to help manufacturers increase efficiency, improve quality, and reduce downtime. Keep reading to learn more, or contact us to discuss your specific application.

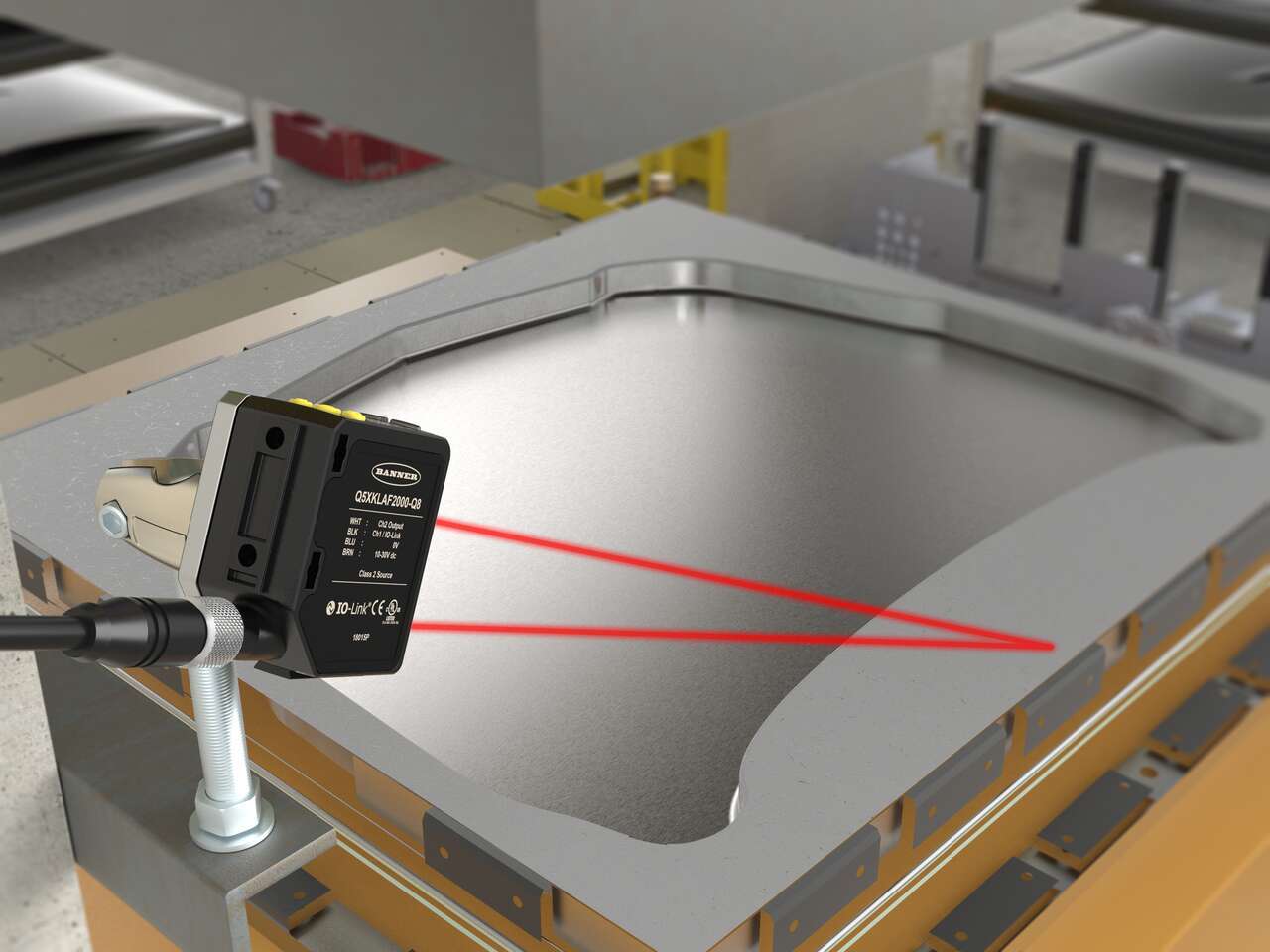

- Laser measurement sensors are often a reliable solution to error-proofing applications.

- Laser sensors from Banner detect and measure the most challenging targets, for error-proofing solutions manufacturers can trust.

- For example, in metal stamping applications, it is critical to ensure that metal sheets are properly indexed on the press before stamping to avoid material waste and damage to the press die.

- The Q5X Series laser sensor reliably detects reflective targets even at an acute angle.

- The press cannot operate until the sensor verifies the leading edge of the material and confirms that the metal sheet is both present and properly indexed.

- In some applications, a vision solution can be an excellent choice for error-proofing.

- For example, in automotive assembly, interior trim pieces are interchangeable, but vary in color, making it easy to install the wrong piece. As assembly progresses, correcting errors becomes more difficult.

- An iVu Color vision sensor verifies that trim colors match the build order for a vehicle.

- If an error is detected (the wrong color trim is placed), the error must be remedied before the automotive assembly can proceed to the next step.

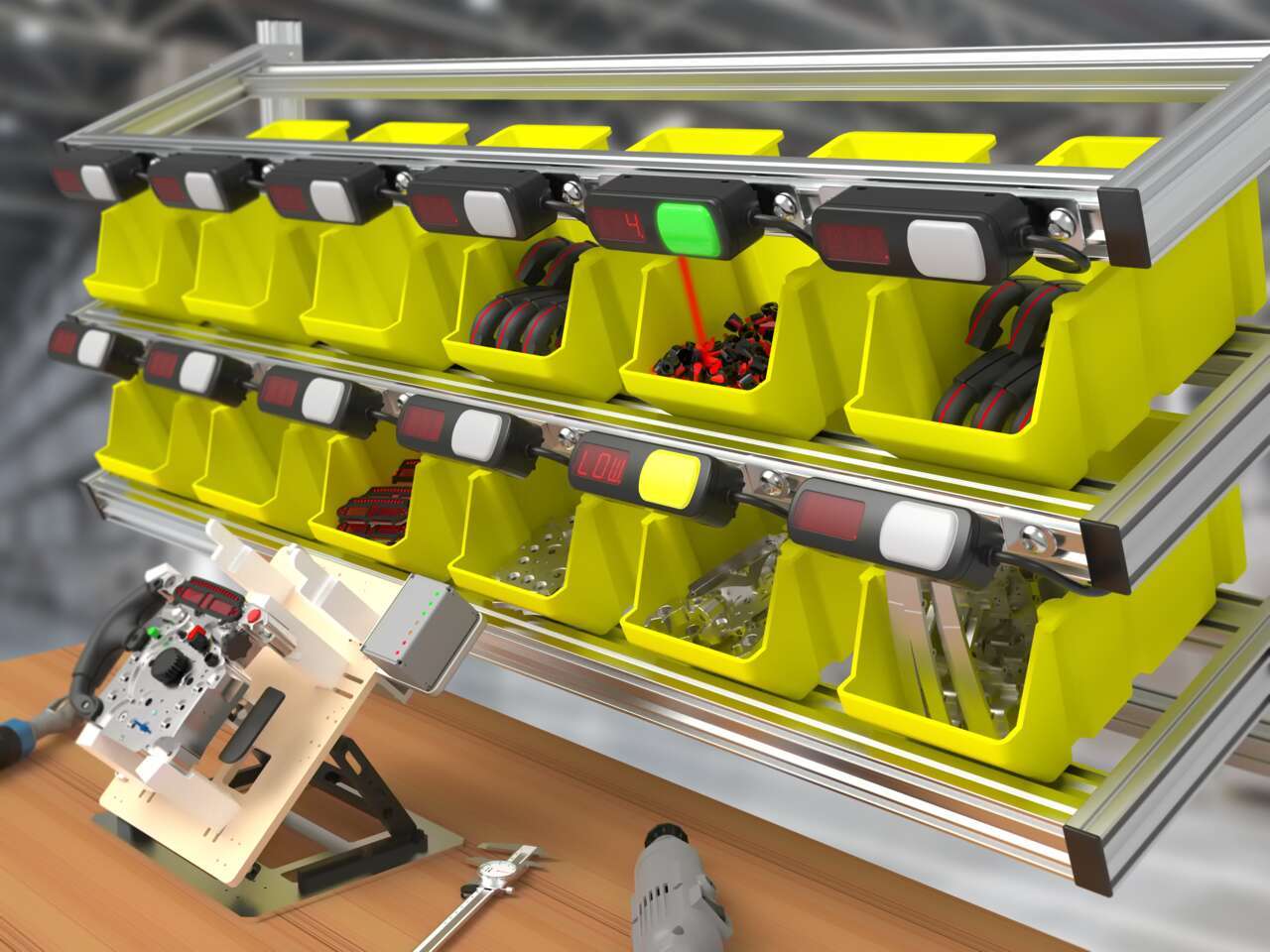

- Perhaps one of the most common error-proofing technologies in assembly processes is light-guided picking, also known as pick-to-light.

- Pick-to-light devices use colored LEDs to visually guide assemblers to pick the correct parts, in the right quantities, and in the proper sequence.

- This reduces the risk of human errors and speeds up build times to ensure high quality while maximizing productivity.

Rugged Laser Distance Sensor

Sensores de distância a laser versáteis e robustos que oferecem alto desempenho e são capazes de detectar mudanças de distância submilimétricas.

- Modelos discretos, analógicos (0 a 10 V ou 4 a 20 mA), para objetos transparentes e com IO-link disponíveis

- Alcance do sensor a partir de 25 mm até 610 mm

- Detecta uma grande variedade de cores, materiais e superfícies de alvo com base na distância

- O modo dual TEACH (intensidade + distância) é ideal para aplicações de verificação de erros e permite a detecção de objetos transparentes sem a necessidade de retrorrefletores

- Corpo robusto de aço inoxidável de grau FDA com classificação IP69K

Vision Sensor

The iVu and iVu Color Image Sensors are used to monitor parts for type, size, orientation, shape, location, and color or color variations.

- All-in-one solution with camera, controller, lens, and light included in one package

- Configure in minutes using Vision Manager PC software, onboard touchscreen display, or remote touchscreen

- Inspect multiple points with a variety of grayscale or color tools

- Compact, rugged, IP67 housing available with integrated ring lights including red, blue, green, white, infrared or UV

- Interchangeable lenses, including C-mount, for maximum application flexibility

- EtherNet/IP™, Modbus/TCP, PROFINET®, PCCC, and Serial RS-232

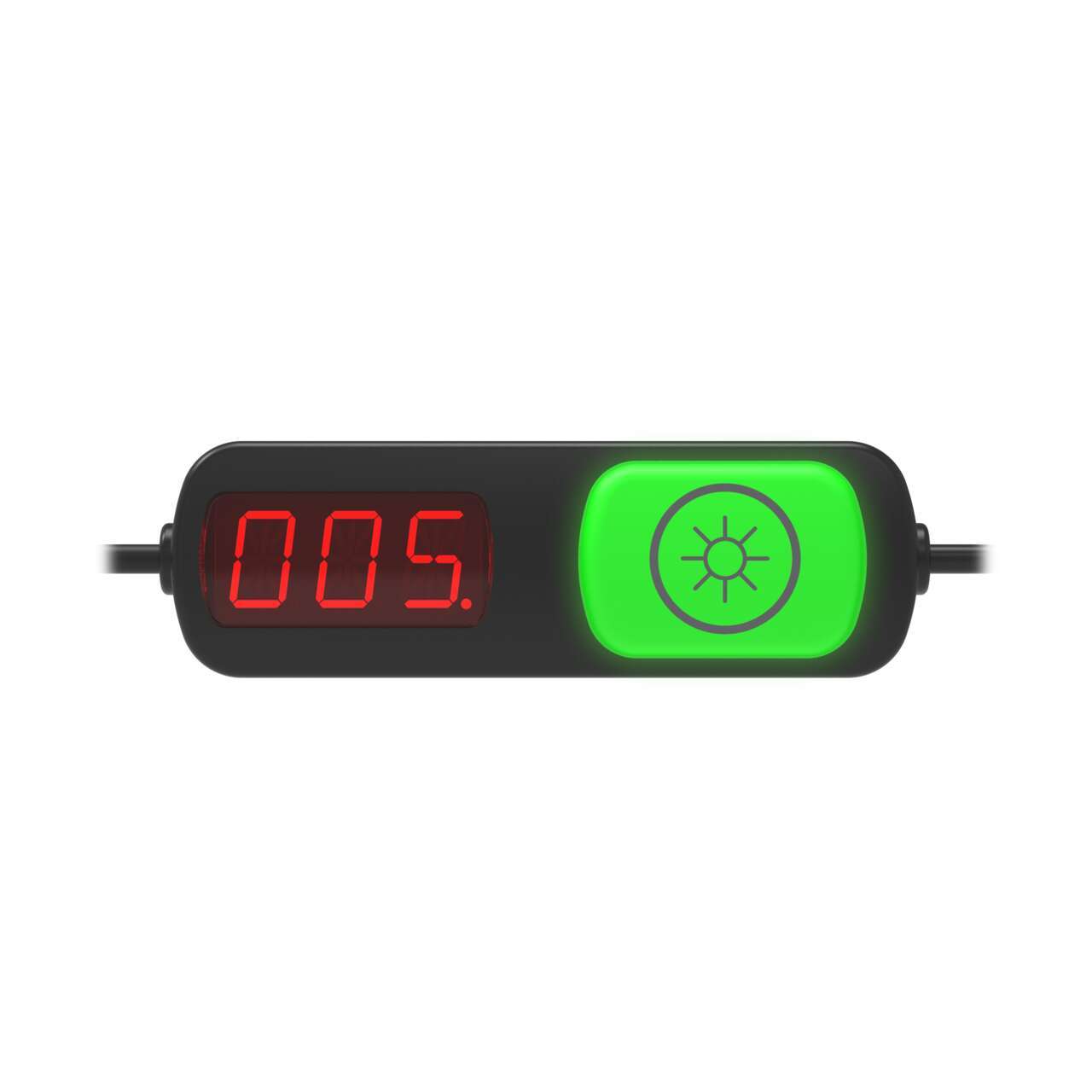

PTL110 Series

Scalable, Versatile Pick-to-Light Devices

Os dispositivos pick-to-light PTL110 são indicadores multifuncionais com opções de botão touch, sensor óptico e display de três dígitos, conectados em série para criar um sistema de coleta potente. Com tempos de resposta rápidos e opções de instalação flexíveis, os sistemas PTL110 melhoram a velocidade, a produtividade e a qualidade em coleta, montagem de kits e aplicações relacionadas.

- Modelos disponíveis com recursos de sensores touch e ópticos.

- O display alfanumérico de 3 dígitos opcional pode ser usado para indicar a contagem de peças ou fornecer outras instruções.

- Conectores M12 para instalação rápida e segura de vários dispositivos sem a necessidade de cabos adicionais.

- O indicador fornece quatorze cores e várias funções de animação para diferenciar várias condições.

- Operação feita por PICK- IQ™, um protocolo de barramento serial compatível com Modbus especialmente construído que utiliza uma identificação comum para reduzir a latência típica resultante da pesquisa de vários dispositivos.

- Podem ser combinados com o controlador sem fio DXM700 para implantação em carros e estações móveis de coleta.

![Operator Guidance Solution [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)