主要食品包裝解決方案

-

Improve Overall Equipment Effectiveness by Monitoring Production Input and Output

Improve Overall Equipment Effectiveness by Monitoring Production Input and Output

Monitoring production inputs and outputs provides machine operators and managers with critical data about their processes and equipment and can help them identify and resolve problems on the production line more quickly.

-

Clear Plastic Food Container Detection in a Sanitary Environment

Clear Plastic Food Container Detection in a Sanitary Environment

Clear, thermoformed plastic containers, trays and clamshells are used to package a wide variety of products. Packagers must be able to detect the leading edge.

-

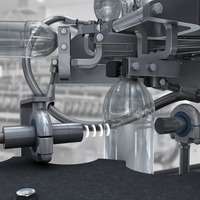

在沖洗環境中偵測透明玻璃和塑膠聚酯瓶

在沖洗環境中偵測透明玻璃和塑膠聚酯瓶

Detect clear glass and PET plastic bottles with various shapes and sizes. Washdown environment, IP69K ratings.

-

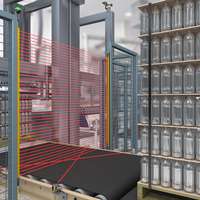

單行裝瓶機的生產線內聚積

單行裝瓶機的生產線內聚積

The Q5X laser sensor reliably detects when the staging area is clear of bottles and the system is ready for the next layer of containers, despite the transparency of the bottles and unstable signal.

-

Detecting PET Bottles to Regulate Product Flow

Detecting PET Bottles to Regulate Product Flow

Sensor solutions to detect translucent bottles in a range of shapes, sizes, colors and contours in a high-speed air conveyance system, identifying gaps.

-

Clear Glass Jar Detection for Food and Beverage Splash Zone

Clear Glass Jar Detection for Food and Beverage Splash Zone

Sensor solutions to detect clear glass jars to be filled with food in a strict sanitary environment where frequent, high-pressure washdowns and IP69K ratings.

-

Detecting Transparent Bottles in a Washdown Environment

Detecting Transparent Bottles in a Washdown Environment

Sensor solutions to detect accumulations to regulate line pressure where bottles vary in size, shape, color, and translucence and there is not a reflector.

-

Clear Container Detection in a Clean-in-Place Rotary Filler

Clear Container Detection in a Clean-in-Place Rotary Filler

Sensor solutions to detect bottle types vary in size, shape, color, translucence, and material. Equipment is regularly exposed to harsh washdown.

-

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Sensor solutions to detect bottle types vary by size, shape, color, contours, and translucence on a rinser where equipment is regularly exposed to washdowns.

-

Clear Tray Detection at Hopper Food Storage Units

Clear Tray Detection at Hopper Food Storage Units

Learn how the Q4X detects clear plastic trays at hopper and filling station in the food industry.

-

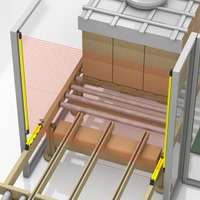

利用遮蔽功能提供裝卸空瓶棧板機械防護

利用遮蔽功能提供裝卸空瓶棧板機械防護

LS 光幕是直觀、易於使用的安全裝置,可用於機器防護。專為生產線上各種危險的安裝環境所打造 LS-S 系列無需使用 PC 軟件、DIP 開關或其他設備即可快速、輕鬆地進行設定。

-

Safety Light Screens Guard Operators from Sweep Bar

Safety Light Screens Guard Operators from Sweep Bar

EZ-Screen LP 4型安全光幕為卸空瓶棧板機的操作人員提供針對掃測桿的運動的安全防護。為向個人提供針對掃除桿的安全防護,在光束之間提供14mm解析度,以防止進入和受傷。如果個人或物品觸及EZ-Screen的光束,則掃除動作將停止,以防止傷害。光幕的小型設計允許沿機器輕鬆安裝,不需要安裝PC或額外的設備。

-

Depalletizer Guarding with Muting Pair

Depalletizer Guarding with Muting Pair

我們的EZ-SCREEN遮蔽光幕的設計允許棧板進出產線,同時使危險區域得到安全防護,當有人員進入該區域時關閉機器。EZ-SCREEN上的遮蔽功能允許產線移動棧板滑軌,不需關閉或重啟機器,而關閉或重啟機器通常會降低生產線的生產速度及效率。在飲料業中,有些機械組裝過程要順利運行,必須使用遮蔽功能選項。

-

讀取多個一維和二維條碼

讀取多個一維和二維條碼

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

-

Level Monitoring On Rotary Filler System

Level Monitoring On Rotary Filler System

Banner’s SureCross wireless system can easily transmit temperature, pressure and fill levels to a local PLCs. The wireless system will seamlessly alert operators if bottling is occurring below the desired fill level. This helps prevent errors and leads to greater consistency in bottled beverages. Consistent fill levels mean no recalls—and no wasted products. Using a wireless system also eliminates the need for slip rings on the rotary filler, which in turn reduces maintenance costs.

-

Non-Contact Fill Level Verification

Non-Contact Fill Level Verification

Banner’s QS30H2O sensor is a specialized sensor developed to address challenges with sensing the presence of water and water-based liquids. The QS30H2O operates in a through beam sensing mode and the emitter uses a wavelength that is tuned to not pass through water. The high excess gain of the sensor makes it powerful enough to see through an assortment of plastic and glass containers. Two pairs of sensors can be utilized to determine that the fill level has met minimum but is not overfilled and wasting product. Apertures can be placed on the receiver end to minimize the beam pattern and increase accuracy of the application. This ensures products that do not meet fill level criteria are not processed or shipped.

-

以無線解決方案替代集電環

以無線解決方案替代集電環

滑環不斷運動,唯有不斷維修才能避免因正常磨損和碎屑造成的旋轉電氣連接退化。集電環故障導致生產停止,造成預料之外及昂貴的停機時間。DX80無線無線電提供了一種非接觸式解決方案,將感測器信號從裝填機碗內傳輸到控制面板。位於迴轉式裝填機上的無線節點可由電池供電,為感測器的無線安裝提供電力。DX80無線解決方案無需集電環,有助於減少停機時間和維修需要。