所有食品解決方案

-

Thermal Remediation Temperature Measurement [Success Story]

Thermal Remediation Temperature Measurement [Success Story]

The EPA has placed restrictions on the use of many fumigants citing a correlation between their use and ozone depletion. As an alternative, a large-scale flour mill performs three to four thermal remediations per year to eradicate flour beetles. The temperature inside the mill is brought up to 122° F (50° C). This is done gradually to minimize equipment and building strain caused by heat expansion.

-

Refrigeration System Monitoring with a Wireless Network

Refrigeration System Monitoring with a Wireless Network

A resistance temperature detector senses the temperature of a walk-in cooler and sends the data to a SureCross FlexPower Node. The Node in turn sends that data to a Gateway, which issues an alarm to management if the temperature exceeds acceptable limits. The DX80 FlexPower Nodes have a IP67 rating for rugged environments and work well in the cold.

-

Monitoring Pressure Levels on an Industrial Refrigeration System

Monitoring Pressure Levels on an Industrial Refrigeration System

Performance Series all-in-one wireless pressure sensors make it easy to monitor pressure levels in large and complex systems from any network-enabled location.

-

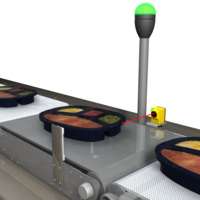

Clear Plastic Food Container Detection in a Sanitary Environment

Clear Plastic Food Container Detection in a Sanitary Environment

Clear, thermoformed plastic containers, trays and clamshells are used to package a wide variety of products. Packagers must be able to detect the leading edge.

-

對輸送帶上的多色亮面包裝進行計數

對輸送帶上的多色亮面包裝進行計數

Sensor solutions to verify packaging and count on conveyor. Foil and film packaging such as tea bags, multiple colors on packaging material.

-

Clear Glass Jar Detection for Food and Beverage Splash Zone

Clear Glass Jar Detection for Food and Beverage Splash Zone

Sensor solutions to detect clear glass jars to be filled with food in a strict sanitary environment where frequent, high-pressure washdowns and IP69K ratings.

-

Detecting Reflective Packages on a Conveyor

Detecting Reflective Packages on a Conveyor

Sensor solutions to detect reflective food wrappers such as Mylar with conveyor belt presence verification, utilizing foreground suppression.

-

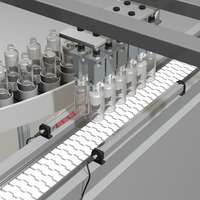

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Sensor solutions to monitor a conveyor to ensure there are no stuck bottles when bottles are clear plastic in a large sensing area.

-

Clear Tray Detection at Hopper Food Storage Units

Clear Tray Detection at Hopper Food Storage Units

Learn how the Q4X detects clear plastic trays at hopper and filling station in the food industry.

-

Guarding Personnel at Meat Slicing Machine in a Harsh Environment

Guarding Personnel at Meat Slicing Machine in a Harsh Environment

Safety light screens on a meat slicer protect operators from sharp blades while in operation. The environment is harsh and frequently exposed to chemical washdowns. The EZ-SCREEN LS with hygienic enclosure keeps personnel safe while preventing water and chemical damage to the light screen.

-

Safety of a Plastic Film Heat Sealer

Safety of a Plastic Film Heat Sealer

Learn how magnet switches protect operators from the harmful interior of a heat sealer.

-

監控包裝機上的安全門

監控包裝機上的安全門

Learn how SI-RF Series safety switches can be used to monitor multiple guard doors, ensuring the highest levels of safety, and making it easy to identify and resolve issues.

-

Illuminating Inside A Cartoner

Illuminating Inside A Cartoner

Banner’s WLS28 LED Light Strips allow operators to identify frozen dinners that have not properly entered a carton and fix the problem with minimal downtime. Their long-lasting and durable cool white light means they’re an energy-efficient solution for illuminating the inside of a cartoner. IP69K rated, they can handle frequent machine wash down procedures.

-

Level Monitoring for Washdown Environments

Level Monitoring for Washdown Environments

Banner’s U-Gage QT50U ultrasonic sensor excels at the most challenging level applications, bouncing sound off any solid surface—even those that may vary in consistency or contrast. The sensor is available with a Teflon-coated transducer cover, making it resistant to harsh chemicals and suitable for the food and beverage industry. Ultrasonic sensors are able to provide accurate monitoring of pump-controlled tanks by sending a continuous signal to measure the current tank depth.

-

Consistent Dough Height Measurement [Success Story]

Consistent Dough Height Measurement [Success Story]

The dough for one of the company’s many popular breakfast cereals must fall within specific height parameters to ensure that it will have the perfect flake. Dough that is too thick will emerge from baking stiff and heavy. Dough that is too thin will crumble easily. This impacts the quality, taste and texture of the final product as well as product weight and packaging. Any product that does not meet the rigorous quality standards of the company will not be shipped or sold on the consumer market.

-

Accurately Measuring Bakery Ingredients [Success Story]

Accurately Measuring Bakery Ingredients [Success Story]

Baking is a mixture of creativity, precision and attention to detail. The Wilkinson Baking Company has added technical innovation to the mix. The Wilkinson Bread Bakery is a compact, completely self-contained and fully automated bread bakery. This unique machine combines technology with tradition to transform simple raw ingredients into bakery fresh bread at 40 loaves an hour.

-

監控高容量料斗內的物料高低

監控高容量料斗內的物料高低

Banner’s LTF Series Laser Measurement Sensor features high excess gain, superior signal control and automatic adaptive laser power control. These features enable reliable detection of the chewing gum from up to 12 meters away, regardless of color or reflective surfaces inside the hopper.

-

Tension Loop Control for Clear Plastic

Tension Loop Control for Clear Plastic

The S18U Series Ultrasonice Sensor monitors loop control on a food packaging line to detect any breaks or tears in the clear plastic film. The S18U detects targets regardless of color or transparency.

-

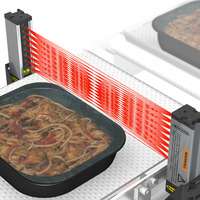

Leading Edge Detection of Packages with a Thin, Flexible Edge

Leading Edge Detection of Packages with a Thin, Flexible Edge

Banner’s LX Series is an economical solution for detecting the leading edge of flat objects, such as the frozen dinner containers. With a web of modulated light, the LX Series part-sensing light screen can detect any item—in any position—passing through the light screen.

-

Loop Control for Clear Plastic

Loop Control for Clear Plastic

The analog U-GAGE S18U ultrasonic sensor positioned below a web of clear plastic monitors the tension of the loop, signaling the rate of uptake to increase or decrease as needed.

-

檢測多通道輸送機上的冷藏早餐卷

檢測多通道輸送機上的冷藏早餐卷

顏色多變的深色包裝很難用傳統的紅色LED感測器進行檢測。Banner Engineering的微型VS8光電感測器,帶有藍色LED,特別適用於低反射率標籤,可以檢測加壓罐中的冷藏食品。小型感測器適合狹小空間,適用於短距離應用。藍色LED與小光斑配合使用,以最大限度地減少標籤上顏色轉換的影響。

-

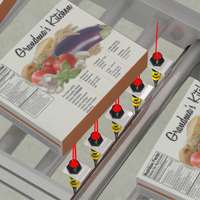

食品箱上的日期/批號驗證

食品箱上的日期/批號驗證

Banner堅固的PresencePLUS P4密封式OMNI視覺感測器適用於日期/批號的驗證,因為它使用光學字元驗證/OCV檢查,以確保正確的日期和批號被清晰列印。這款感測器的外殼的防護等級為IP68,是食品和飲料應用的理想之選,因為它可以承受嚴酷的沖洗環境。P4 OMNI感測器透過驗證紙盒的邊緣,輕鬆找到需要進行日期/批號檢測的紙盒的相應區域。Wi

-

偵測防偽封膜的位置和有無存在

偵測防偽封膜的位置和有無存在

Banner iVu TG視覺感測器具有多點檢測功能,是偵測和評估防偽封膜的位置的理想選擇。在此應用中,防偽封膜應位於瓶子的瓶蓋和頸部周圍。認為位置太高、太低或完全缺失的密封是不可接受的。透過多點檢測,iVu TG視覺感測器可以同時偵測防偽帶缺失和位置不佳。

-

檢測在包裝線上是否缺少巧克力

檢測在包裝線上是否缺少巧克力

Banner感測器放置在輸送帶上方,檢測每個通過的盒子是否缺少巧克力。當一個通過的盒子觸及由一對Q12對比模式感測器產生的感測光束時,安裝在盒子上方的QS18AF感測器陣列將檢測每個位置是否缺失巧克力。當檢測到包含錯誤數量的巧克力的盒子後,輸出訊號被轉送到包裝線上的主控制器,以警告存在故障條件。

-

Detecting Different Size Packages on a Conveyor

Detecting Different Size Packages on a Conveyor

Banner’s S18-2 barrel sensor is a cost-effective, reliable sensing method for this type of application. Its small size makes it easy to integrate along the manufacturing line, and its competitive price means it is well-suited for applications requiring multiple sensors. With a powerful and bright visible red emitter beam, the S18 sensors are easy to align during set up.

-

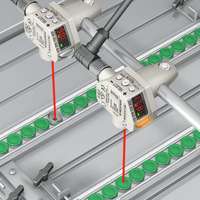

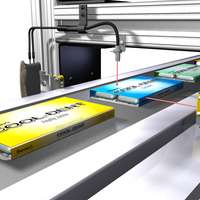

Carton Trigger For Date/Lot Code Printing

Carton Trigger For Date/Lot Code Printing

With a narrow beam that projects a small bright spot, the QS18LLP laser, polarized, retro-reflective sensors provide precise position control when triggering various devices. In this application, the QS18LLP is able to correctly detect the glossy carton as it travels down the conveyor—without proxing—and trigger the ink jet printer to print the date/lot code on the carton. The second sensor triggers the P4 OMNI to inspect the date/lot code and verify it is legible and correct.

-

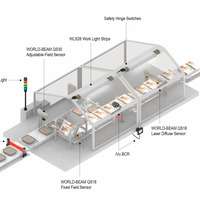

在紙盒包裝機上包裝冷凍食品

在紙盒包裝機上包裝冷凍食品

WLS28直線型工作燈條:明亮耐久的LED直線型工作燈可在紙盒包裝機內提供最佳能見度,方便操作人員使用,並可輕鬆安裝在機器上,不會阻擋安全鉸鏈開關:如果門打開,不銹鋼、承重安全鉸鏈開關可支持紙盒包裝機的機門,並將機器關閉,儘可能減少蓄意失敗的風險

-

在核對食物重量時進行感測

在核對食物重量時進行感測

EZ-BEAM Q25反射板式感測器適用於此應用。它可發射一個高功率光束,可靠地偵測任何通過秤的黑色物體。如果要偵測透明的物體,則使用Q25偏光反射板式型號。Q25有IP69K保護等級的外殼,經得起食品應用中刺激的沖洗。安裝簡單;Q25無需調整。

-

Counting Food Cartons for Correct Packaging

Counting Food Cartons for Correct Packaging

Banner’s WORLD-BEAM QS18LP laser sensor accurately inspects every carton that passes on the conveyor, ensuring the robot is triggered to load cartons into the package. With a visible laser sensing beam, the QS18LP provides precise position control, which is ideal to ensure accurate counting of cartons at a close range. The rugged QS18LP is also ideal for confined spaces and is easily set up along a conveyor for accurate sensing. With highly bright LEDs, operating status is visible from 360⁰.

![Thermal Remediation Temperature Measurement [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Consistent Dough Height Measurement [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/L-GAGE-LH--Cereal-Dough-Thickness-Inspection.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Accurately Measuring Bakery Ingredients [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)