Vision Sensor

iVu Series

The iVu and iVu Color Image Sensors are used to monitor parts for type, size, orientation, shape, location, and color or color variations. The device can be set up and monitored using an integrated or remote touchscreen or with a PC. The following features are available:

- Setup, Manage, and Monitor iVu Series Devices with an Integrated or Remote Touchscreen or with a PC

- All-in-one solution with camera, controller, lens, and light included in one package

- Configure in minutes using Vision Manager PC software, onboard touchscreen display or using remote touchscreen to access to hard to reach places

- Highly capable image sensors to solve a wide range of vision applications, such as item detection, matching, part positioning or color verification

- Inspect multiple points with a wide variety of grayscale or color tools, depending on your application

- Compact, rugged, IP67 housing available with a variety of integrated ring lights including red, blue, green, white, infrared or UV

- Interchangeable lenses, including C-mount, for maximum application flexibility

- Factory communications (EtherNet/IP™, Modbus/TCP, PROFINET®, PCCC and Serial RS-232) for integration on the manufacturing floor

- Ability to change parameters on the fly with full runtime editing to reduce costly downtime

Downloads

Literatura Técnica

Archived Software

Folhetos e Catálogos

Application Notes

-

![Combined Inspections Used to Meet Quality Standards [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-PLUS-TG-Cap-and-Orientation-Inspect_Detergent.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

-

![Accurate Label Inspection [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/CustomerImage_RemoteViewsCloseUp.jpg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Accurate Label Inspection

-

Indicação de Fim de Lote

-

Leitura de Códigos de Barras Industriais para Correio Inteligente

-

![Presença de Tubos de Ventilação na Enchedora [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Presença de Tubos de Ventilação na Enchedora [História de Sucesso]

-

Date/Lot Code Presence or Absence Detection

-

Blister Pack Inspection

-

Part Orientation

-

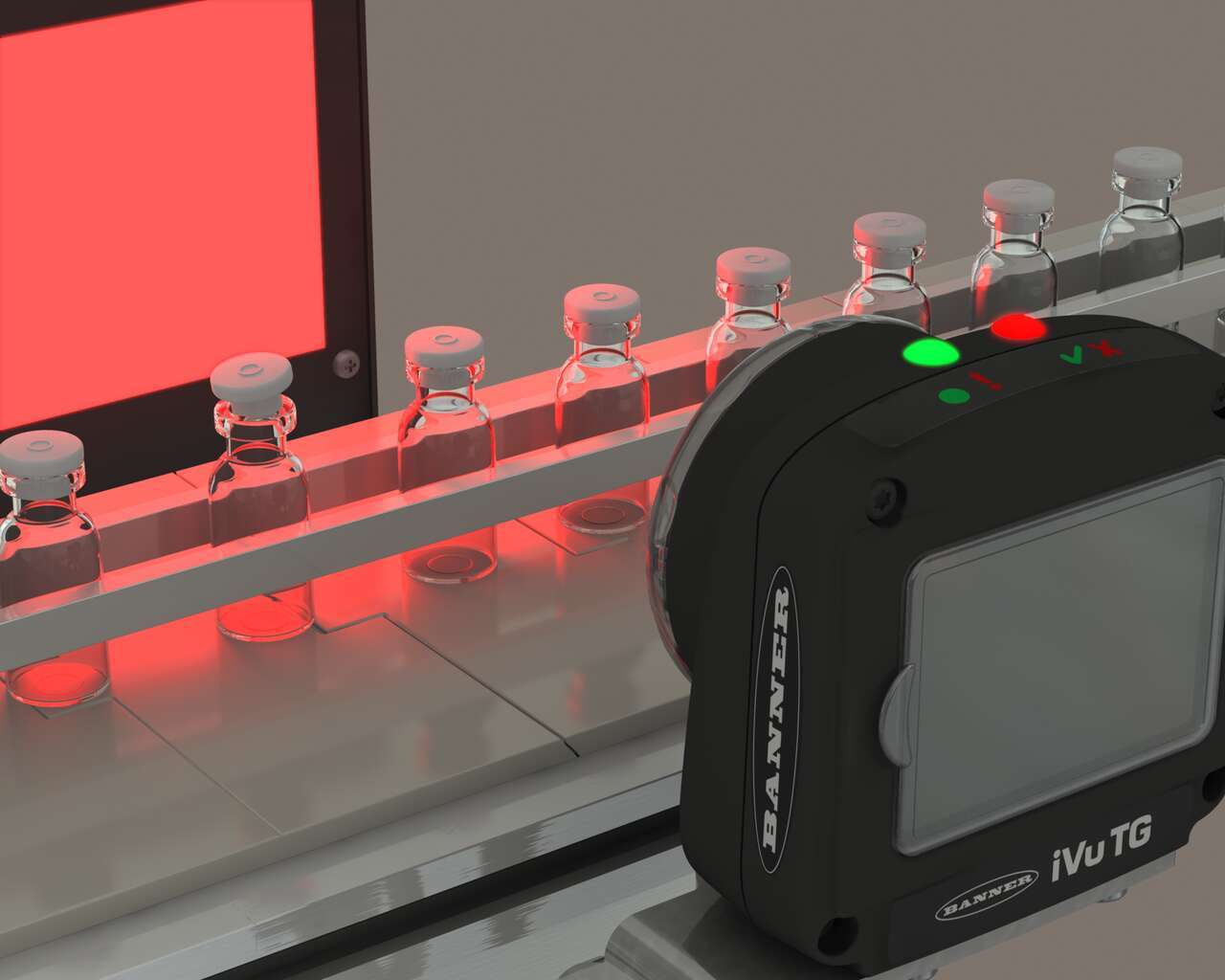

Inspection of Stoppers in Vials for Correct Seal

-

Inspecting Bottles for Cap Presence and Correct Color

-

Detecting the Positioning and Presence of Tamper Evident Bands

-

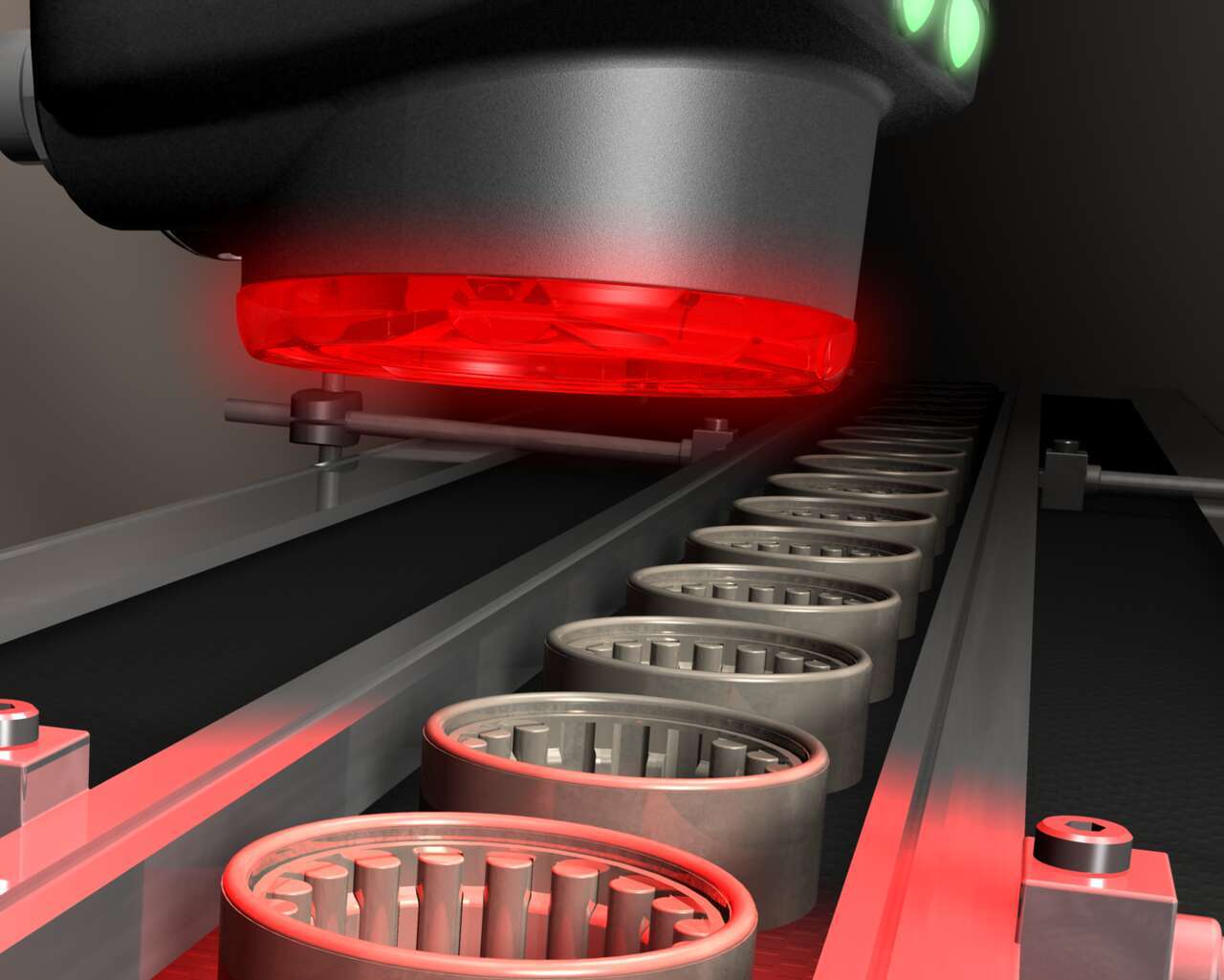

Bearing Inspection

-

Punch Hole Inspection

-

Small Part Inspection in Tough Location

-

Food Packaging Label Inspection

-

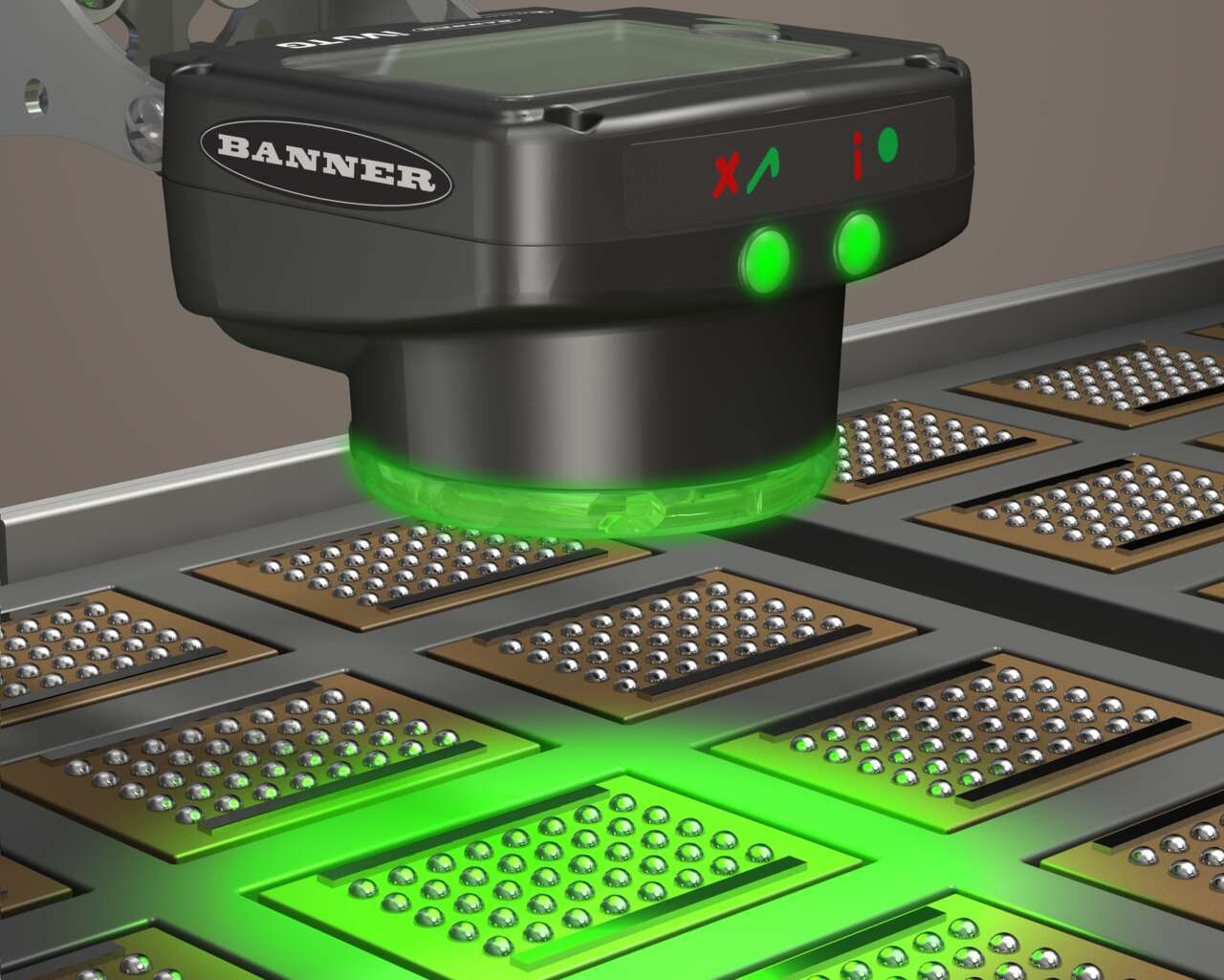

Solder Ball Inspection

-

Box Insert Detection

-

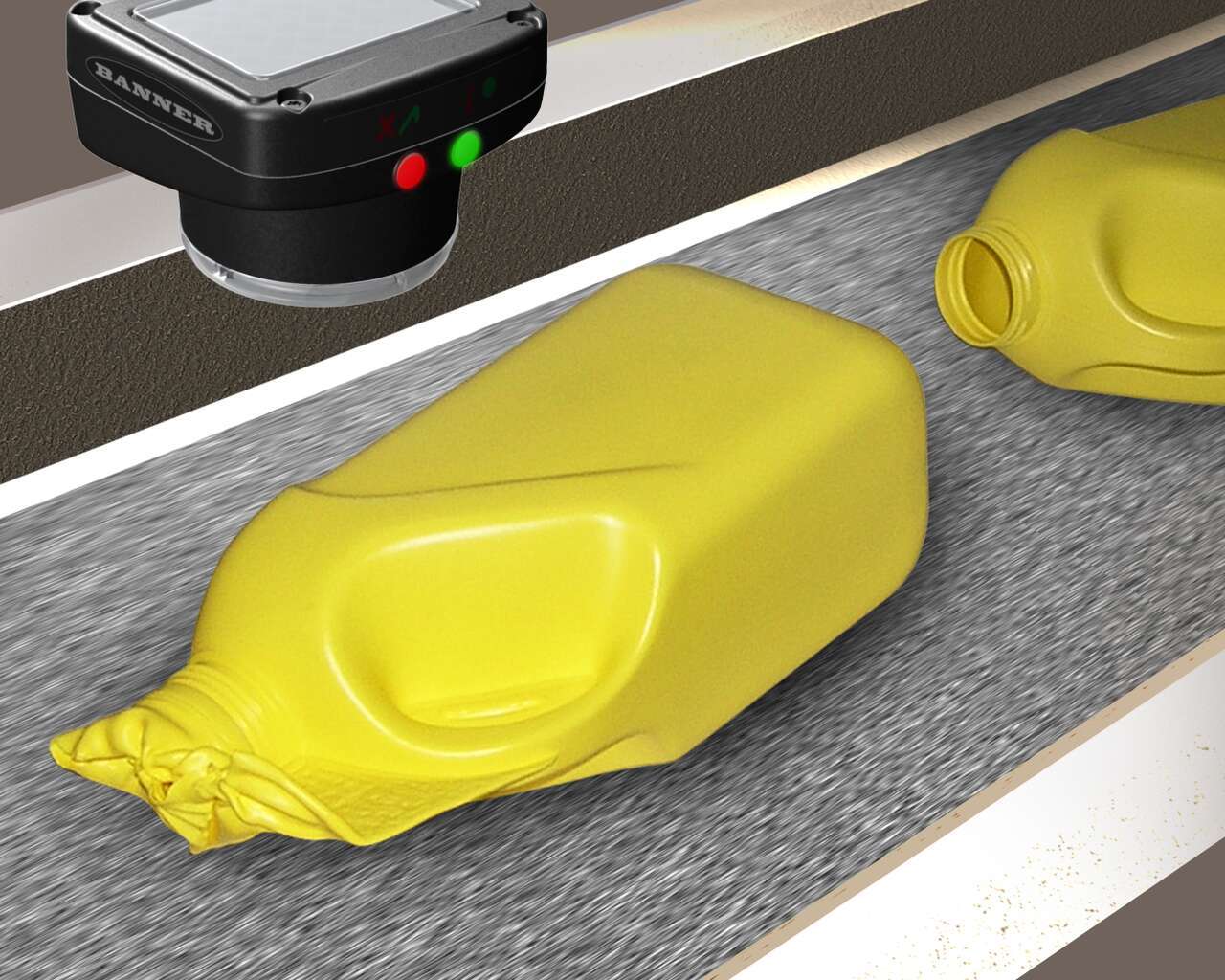

Orientation Verification

-

Blemish Detection on Bandage

-

Correct Label Verification

-

Part Color Inspection on a Vehicle Door Panel

-

Label Alignment Inspection

-

Date/Lot Code Inspection

-

Label Inspection

-

Electronic Marking Verification

-

Injection Molding Inspection

-

Drilled Holes Inspection

-

Error Proofing for Integrated Circuit Chips Loaded into Pocket Tape