所有汽車業解決方案

-

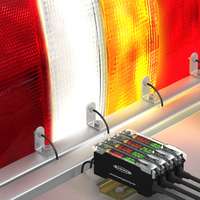

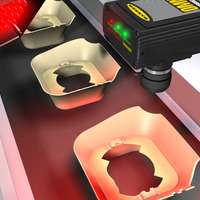

Temperature Sensor Detects Defrost Wires [Success Story]

Temperature Sensor Detects Defrost Wires [Success Story]

An automotive manufacturer was rejecting a supplier’s shipment of rear window assemblies due to faulty defroster grids. The supplier’s existing test procedure measured current draw across the entire heating system to detect an overall failure, but it could not detect the subtle impact of a single heating wire being broken. The window supplier partnered with a Michigan-based machine automation company to create a better test fixture—one that can verify each defrost wire heats to specification prior to shipping.

-

Motor Temperature Monitoring and Control with a Wireless Network

Motor Temperature Monitoring and Control with a Wireless Network

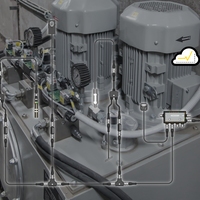

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered SureCross Node and a Banner T-GAGE temperature sensor. When using host control systems, the SureCross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

-

從監控站進行設備狀態監控

從監控站進行設備狀態監控

• Provide at-a-glance machine status indication • Send machine status information to a wide range of devices • Alert staff and supervisors of critical conditions via text message or email

-

Restocking Assembly Stations for a Continuous Workflow

Restocking Assembly Stations for a Continuous Workflow

• Restock assembly stations before components run out without overstocking • Provide real-time communication between assemblers and the forklift operators who supply them • Monitor delivery efficiency

-

Call for Pickup from an Assembly Station to an AGV

Call for Pickup from an Assembly Station to an AGV

• Remove completed pallets from assembly stations quickly • Enable direct communication from assembly stations to AGVs • Improve process efficiency using turnaround time data to

-

Warning Indication where Obstructions Limit Visibility

Warning Indication where Obstructions Limit Visibility

• Provide high-visibility warning indication • Minimize risk to staff in high-traffic forklift area • Facilitate the flow of traffic through an area with visual obstructions

-

Remote Monitoring to Optimize Overall Equipment Effectiveness

Remote Monitoring to Optimize Overall Equipment Effectiveness

• Provide instant visual communication across a busy plant floor • Collect machine status and other data to calculate Overall Equipment Effectiveness (OEE) • Alert staff to critical conditions via text message or email

-

機台控制箱內的環境監測

機台控制箱內的環境監測

• Identify small problems before they become major issues that impact machine performance and uptime • Access environmental data from a remote location • Notify operators of critical conditions via text message or email

-

Status Indication on Driverless Vehicles [Success Story]

Status Indication on Driverless Vehicles [Success Story]

The K50L domed 50 mm indicator light works well for status indication on autonomous shuttle buses. The buses operate on short distances in outdoor environments that exposed the bus technology to a variety of weather conditions. The rugged K50L indicators are rated IP67 and IP69K to withstand water ingress in the harsh environment.

-

Multicolor Indicators and Illuminated Touch Buttons Simplify Machine Panels

Multicolor Indicators and Illuminated Touch Buttons Simplify Machine Panels

S22 Pro Series touch buttons and indicators simplify control panel design and improve operator experience and performance. Pro Editor software expands the built-in display capabilities available with the S22 Pro Series, enabling custom displays.

-

Assembly Timer at Busy Work Station

Assembly Timer at Busy Work Station

K50 Pro touch buttons with IO-Link communication display takt time within workers' sightlines so that the assembly pace stays on track and meets production goals.

-

Monitor Leaks in Your Critical Applications

Monitor Leaks in Your Critical Applications

Monitor leaks in your critical applications and receive real time alerts when they occur.

-

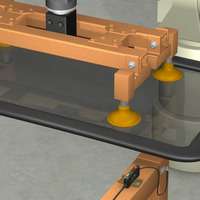

Detect Installed Glass on Automobile

Detect Installed Glass on Automobile

Sensor solutions to detect the presence of a moonroof on an automobile assembly line where extended range capabilities are required.

-

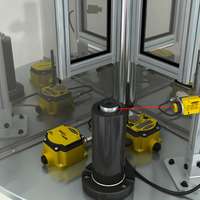

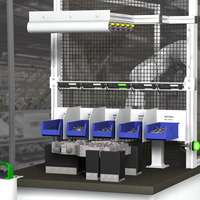

Manual Load Weld Cell

Manual Load Weld Cell

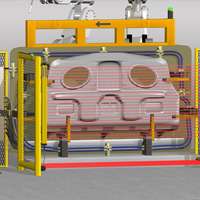

Banner的EZ-SCREEN®系列安全光幕系統是針對焊接設備的苛刻的惡劣環境要求而發展出的完整的解決方案。藉由將多個設備串接(串聯)的能力,可以使用標準配件(非主/從模式)將安全光幕以水平/垂直的方式安裝與設定。

-

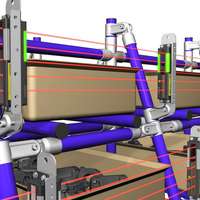

Area and Gate Guarding on Automotive Assembly Line

Area and Gate Guarding on Automotive Assembly Line

汽車沿著輸送帶行進到由EZ-SCREEN光幕保護的危險區域。在汽車接近時,EZ-SCREEN光幕暫時被遮蔽,允許汽車通過而不停止輸送帶。在光幕被遮蔽時,工人可能會通過互鎖的分離安全防護設備嘗試進入危險區域,這會使工人處於危險境地,並導致工人可能被移動的汽車撞到。

-

可追溯性紫外光條碼

可追溯性紫外光條碼

Before shipping to the brand assembler, a supplier of auto visors needs to verify that Data Matrix UV barcodes have been printed on each visor’s safety label. The customer turned to Banner to read invisible 2D Data Matrix barcode and send data via Ethernet IP to a PLC for traceability/error proofing.

-

視覺感測器讀取 QR 碼

視覺感測器讀取 QR 碼

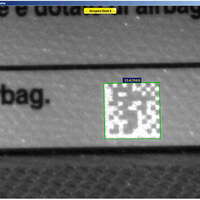

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

讀取汽車零部件上的 DPM 條碼

讀取汽車零部件上的 DPM 條碼

Direct part mark (DPM) codes can be small, complex, and difficult to distinguish from the material they are etched into.

-

操作指導解決方案

操作指導解決方案

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

-

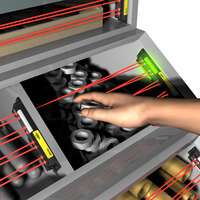

配戴手套進行組裝作業

配戴手套進行組裝作業

Banner的定距式K50指示燈檢測戴有手套的手,用來辨別操作人員在組裝過程中是否選擇了正確的零組件。之後,K50指示燈的邏輯功能可以透過從綠色更改為黃色(也可以選擇其他顏色,以配合製造商的選擇偏好)來通知操作人員其已經正確拾取。K50檢測深色手套的能力對於精益製造過程尤其重要,在此過程中,員工通常配戴深色手套。

-

小箱子的零件拾取指示

小箱子的零件拾取指示

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor with a 400 mm range is interfaced with a process controller programmed with the correct assembly sequence. The controller makes the PVDs light up in the correct order, to show the assembler which part to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD of the next bin in the pick sequence to light up.

-

多產品組裝站光導指示系統

多產品組裝站光導指示系統

PTL110 pick-to-light devices on a multiproduct assembly station are a highly effective way to prevent errors and speed up build time. The optical sensors on PTL devices detect hands as they pass by, confirming that a pick was made.

-

大型工作站的光導引套組

大型工作站的光導引套組

Manual kit building at large stations can be time-consuming and subject to human error, especially if storage racks are difficult to navigate. The PTL110 series pick-to-lights are scalable for large systems and highly versatile to complete numerous tasks.

-

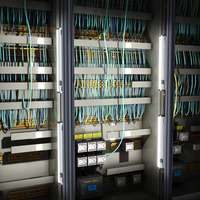

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

An equipment manufacturer builds test and measurement machinery for the auto industry. Operators access machine systems through the control cabinet. Intense illumination of the cabinet facilitates machine maintenance and management. Multiple AC powered fluorescent light fixtures had been used for this task.

-

Superior Light Distribution with LEDs [Success Story]

Superior Light Distribution with LEDs [Success Story]

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

使用綠光LED工作燈偵測表面瑕疵

使用綠光LED工作燈偵測表面瑕疵

Learn how green LED task lights enhance visibility of surface imperfections on manufacturing materials.

-

高品質 LED 工作燈有助於改善品管效率

高品質 LED 工作燈有助於改善品管效率

Automotive inspection requires consistent, bright light with minimal glare to inspect automotive parts. Increased lighting can improve worker productivity and reduce eye strain.

-

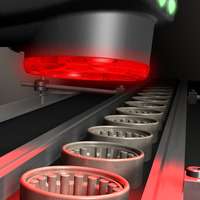

High-Quality LED Lighting for Conveyor Illumination

High-Quality LED Lighting for Conveyor Illumination

Finding a high-intensity, ultra-bright lighting solution for manufacturing can be challenging. Since multiple lights are required to properly illuminate areas on a conveyor, a simple mounting option to connect lights together is needed.

-

Assembly Timer Indication at Automotive Assembly Station

Assembly Timer Indication at Automotive Assembly Station

In automotive manufacturing, maximizing efficiency is crucial in order to meet production goals. Delays at assembly stations can hold up processes later down the line, leading to costly wasted time and missed production targets. The TL50 Pro tower light helps assemblers meet expected cycle times and support overall takt time requirements.

-

Inspecting Small Connectors [Success Story]

Inspecting Small Connectors [Success Story]

An automotive supply company makes a range of vehicle systems. Their seating systems combine structure and design with features that enhance comfort and safety. Weight sensors installed on the underside of the seats work in coordination with vehicle safety systems to determine the size and position of a seat occupant. These factors affect how or if airbags will be deployed in the event of an accident.

-

Sensors to Measure Movement Range

Sensors to Measure Movement Range

During assembly, inspections are conducted to measure seat height adjustment, forward and rearward movement, and upright and recline motion. Two sensors are used for each inspection. The sensors are deployed off the conveyor line to ensure easy access to and the free movement of the seats. At its maximum range during inspection, a seat may be as far as a meter away from the sensors.

-

精確量測曲軸徑向跳動

精確量測曲軸徑向跳動

Crankshaft runout measurements must be monitored continuously to ensure that they meet tolerance requirements. Learn how LM Series laser measurement sensors solve this difficult application.

-

Run Bar提供操作人員指示

Run Bar提供操作人員指示

A leading machine manufacturer builds workstations designed for accurate, timely and cost-effective battery cell assembly. A value added component of the workstations is an operator guidance device that does three jobs: enables assembly processes to start and stop, indicates parts to be picked and installed, and completely stops line operation if emergencies occur. When it became too costly for the OEM to construct and mount these devices themselves, they turned to Banner to craft an all-inclusive solution. To honor the time line requirements of their customer—a major tier two battery supplier—the OEM needed the solution in eight weeks.

-

汽車組裝線上的零件拆卸檢驗

汽車組裝線上的零件拆卸檢驗

在汽車組裝廠會用臨時別針暫時固定一些零件。為了確保臨時別針都有被正確移除,裝有EZ-LIGHT PVA拾取燈感測器的檢測站都有一個回收別針的容器。

-

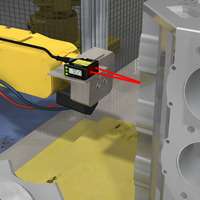

引擎汽缸上的橡膠墊圈偵測

引擎汽缸上的橡膠墊圈偵測

Banner的Q4X多功能雷射感測器很適合進行存在/不存在偵測,即使是高度變化微小的挑戰應用中,例如,確認閃亮金屬零件上存在的小型黑色目標物。墊圈應存在於鑄鋁引擎汽缸體中,如果Q4X偵測到輕微的高度差,即使小至 1 毫米,也會發出信號,警告操作者橡膠墊圈不存在,或是有放入了多個墊圈。Q4X可以在前景消除模式下,透過設定檢測區間來偵測重複橡膠墊圈。

-

偵測黑色門板上的黑色零部件

偵測黑色門板上的黑色零部件

Since door panels are often dark colors such as black or gray, and the foam used to eliminate rattles and provide stiffness is generally black, it can be difficult for standard sensors to differentiate between foam presence and absence due to poor contrast.

-

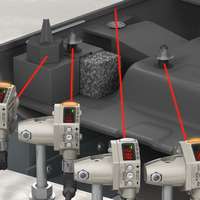

沖壓金屬零部件的多點檢查

沖壓金屬零部件的多點檢查

為了驗證金屬小零部件上存在預期的孔數,可以為多個偵測區域(ROI)設定具有多點檢測功能的iVu Plus TG影像感測器,以確保孔存在並且打孔位置正確。在設定區域檢測時,iVu將掃描沖壓零部件上的多個點,以驗證是否存在某個特征或關注的特徵。

-

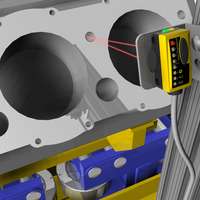

引擎氣缸零部件就位偵測

引擎氣缸零部件就位偵測

Banner的LE550雷射感測器是零部件就位驗證過程的理想選擇。它很可靠,並且對於長距離的小型零部件就位驗證非常準確。LE550採用數位輸出來測量3 mm厚度,確保固定夾存在並且引擎氣缸位於正確的位置。

-

工業捲線機零缺陷標準[成功案例分享]

工業捲線機零缺陷標準[成功案例分享]

一家成功的特種工業紗線製造商為汽車、航空航天、軍事和復合材料行業製造玻璃纖維和玻璃絲線產品。為了保持高標準并盡可能降低產品回報,他們建立了零產品缺陷的目標。為了實現這一目標,公司需要一個自動化絲線檢測系統。

-

Reliably Detect Adhesive Tape on Pouch Batteries

Reliably Detect Adhesive Tape on Pouch Batteries

When manufacturing pouch batteries for electric vehicles, adhesive tape material is used to complete the outer film packaging. The tape’s presence must be confirmed with optical-based sensors for quality assurance purposes. Keep reading to learn how the QCM50 color sensor solves this application.

-

充電站的電動車偵測

充電站的電動車偵測

Banner Engineering’s K50R radar sensor offers an ideal solution for electric vehicle detection at recharge stations. When cars park at a charging station, the radar sensor immediately detects the vehicle’s presence. If separate monitoring indicates that the car is not plugged into the charge station, a signal is sent to a central location, alerting authorities to ticket or remove the vehicle if necessary.

-

Bank Drive-Thru Automobile Detection

Bank Drive-Thru Automobile Detection

Banner Engineering's K50R short-range radar sensor can be used to detect vehicles at bank teller drive-thru windows. It is designed to operate in any outdoor weather conditions.

-

偵測停車位空位狀況

偵測停車位空位狀況

Banner Engineering's weather-resistant K50R short-range radar sensors can be placed above parking spaces in a large, multi-level parking structure to monitor parking availability and help drivers to find open parking spaces more easily.

-

偵測從模具彈出的零部件[成功案例]

偵測從模具彈出的零部件[成功案例]

在製造商的設施中,操作人員手動從模具中插入和移除金屬零部件。在完成後,零部件透過金屬滑槽送入一個箱子。為了防止模具碰撞(在壓機中同時有兩個零部件),客戶需要一個感測器,可以偵測滑槽上的各個零部件,並向控制系統發送一個訊號,表明壓機已經空閑,並允許操作人員執行下一個衝程。需要安裝一個解決方案:無需在滑槽側部的切割槽中或滑槽末端安裝感測器,因為這樣做可能會為行進的零部件產生绊点。

-

繁忙製造地點中的通訊 [成功案例]

繁忙製造地點中的通訊 [成功案例]

隨著更多的組件通過烤箱,與待卸載物品的流動保持同步變得越來越困難。分揀區逐漸變得擁堵。物品容易被引導至錯誤方向或甚至損壞。零部件流動的暫停使得卸貨操作人員可以糾正錯誤並令取貨站保持通暢。不過,卸貨和裝貨區之間的距離以及周圍機器的環境干擾使操作人員之間的通訊變得複雜。

-

光觸控按鈕和緊急停止操作台

光觸控按鈕和緊急停止操作台

緊急停止按鈕為一體成型,與光觸控按鈕結合,為不需要接線或附加機箱的生產線提供簡化的操作人員工作站。Banner的30mm底座E-Stop按鈕很適合這種應用。啟動時,照明基座從黃燈變為閃爍的紅燈,使其符合緊急停止要求。緊急停止按鈕與光觸控按鈕彼此靠近,意味著工人可以快速輕鬆地啟動

-

在環境光線中提供明亮的指示

在環境光線中提供明亮的指示

當的窗戶直接位於電控箱後面時,LED指示燈必需非常明亮、持久的可全天提供高可視性的指示。Banner的EZ-LIGHT K50 信標燈適用於許多指示狀態應用,特別是在這個電控箱中的指示狀態,因為即使在白天信標燈也具有高可視性,並且其使用的節能LED非常持久、耐用。

-

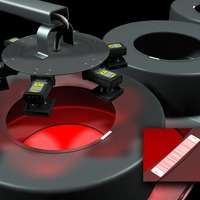

輪胎製造中的模具保護

輪胎製造中的模具保護

如果衝壓機試圖將胎面壓印成尺寸錯誤的無印胎或綠色輪胎,則輪胎壓機中的模具將遭受代價高昂的損壞。為了將每個輪胎引導到正確的壓機,Banner's PresencePLUS P4 BCR 1.3視覺感測器根據列印在輪胎胎圈上的標籤上的條形碼中的識別信息對綠色輪胎進行分揀。在此應用中,在輸送帶上移動的綠色輪胎經過其上安裝有六個BCR 1.3視覺感測器的固定裝置的下方。

-

以無線方式減少及預防停機時間

以無線方式減少及預防停機時間

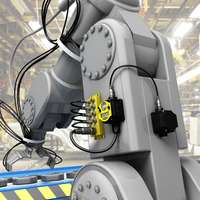

不銹鋼和特殊合金的生產商向金屬鑄造產業供應鋼坯、鋼條和鑄錠。在生產過程中使用機器人來處理鎂鋼坯。位於機器人末端操作裝置上的近接開關,將來自夾爪的狀態資訊傳遞到控制面板上。接近開關必須以機器人電纜連接到控制面板上。環境中的挑戰和機器人的往復運動會造成電纜的疲勞及損壞。停機時間會變得相當頻繁,而且為了維修更換零件,必須停止生產,導致成本增加及生產力的降低。

-

Bypass Capability on a Robotic Work Cell

Bypass Capability on a Robotic Work Cell

Using a 2 or 3-position OS80 key operated selector switch, the operator can bring the robot to a controlled stop, enter the cell, and then quickly resume operations once work in the cell is complete.

![Temperature Sensor Detects Defrost Wires [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/T-GAGE-Defrost-Wire-Inspection.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Status Indication on Driverless Vehicles [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Superior Light Distribution with LEDs [Success Story]](/content/dam/banner-engineering/photography/application-photos/miscellaneous/hofmann_enclosures_wlb32.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Inspecting Small Connectors [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![工業捲線機零缺陷標準[成功案例分享]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![購物中心將車輛引導至有空位的停車場[成功案例]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/kiosks_alt.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![偵測從模具彈出的零部件[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/PVD-Part-Out.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![繁忙製造地點中的通訊 [成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/K50-Touch-and-TL50---Industrial-Oven_For-Andrew.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)