飲料:行業包裝

生產線的終點是產品包裝的最後階段。輸送帶、打棧機、堆高機和工作人員在這個地區聚集,活動幾乎不曾停止。嚴格限制進入該地區的包裝箱流量,及離開該地區的裝載完成棧板流量,以防生產線延誤和停機。還必須採取安全措施,保護人員免於意外或傷害。

我們在感測器、安全控制、LED照明和指示燈的產業知識和專長,讓我們能提供解決方案,解決最終包裝領域一些最困難的應用問題。我們有能偵測有鮮明圖形的目標的感測器、 能偵測透明、亮面包裝的感測器,還能提供業界最完整系列的安全產品,包括重載型安全光幕和可擴充的安全控制器,您大可仰賴Banner的產品改善您的包裝過程,並滿足您一切機器防護要求。

飲料業終端包裝應用

按機器類型查看應用方案

特色應用

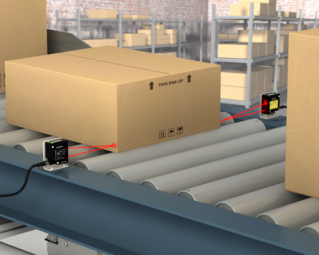

紙盒外形尺寸確定

在輸送帶上移動的紙盒行經兩個LE550雷射感測器,測量紙盒寬度以便正確分揀。LE550感測器是確定紙盒外形尺寸的經濟型解決方案。類比輸出向PLC發送信號,以將紙盒交付到正確的儲存位置。Banner的LE550在測量紙盒的高度、長度和寬度時提供重複性和精準度。雷射感測器具有直觀的使用者介面,便於調整設定。

Safeguarding the Palletizer and Stretch Wrapper

為裝運機和捆包機周圍的區域提供安全防護可能很困難,因為它涉及多重危險。可擴展的安全控制器可以幫助管理與裝運機和捆包機相關的危險,同時確保有效的安全防護過程。

Robotic Palletizer Safeguarding

Banner的XS26-2是一個靈活易用的安全控制器,具有直觀的編程環境,能夠處理當前的機器流程,並且隨著機器自動化裝置的增加或變化,最多可以添加8個I/O擴展模組。支持廣泛的安全設備,允許複雜的應用在最少的時間內組態和下載到控制器,以實現有效的機器調試。

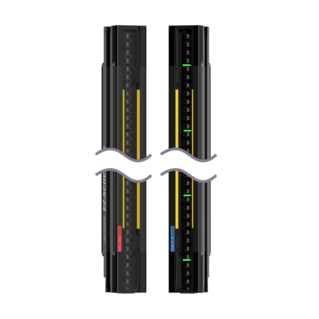

透過視覺指示來指明安全條件

為了維護飲料行業的高效生產線,應立即通知任何安全問題,這一點至關重要。使用視覺和聽覺指示來識別安全問題可以幫助員工快速找到並糾正錯誤 - 以及時將系統恢復到正常運行狀態。

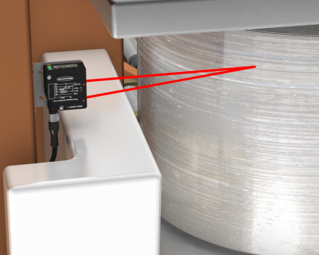

量測塑膠捲直徑

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allows for reliable measurement of the shrink wrap.

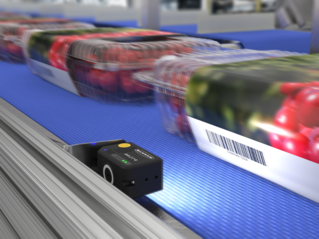

讀取多個一維和二維條碼

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

棧板上的條碼確認應用

如收縮膜包裝棧板等運送物品時可以用條碼標記,以便清楚識別有哪些產品已經準備發貨。我們需要一個感測解決方案,以確認最終的收縮包裝產品標籤正確,且與內容相符。

條碼讀取

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

透過包裝跟踪產品

Barcodes used to track packaged produce through the supply chain contain important product information that must be verified at multiple points during packaging. An ABR 3000 barcode reader ensures that the barcode on each package is present and correct.

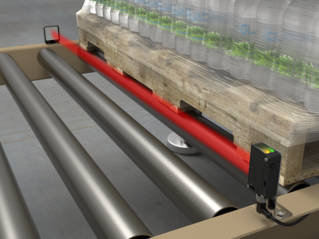

前沿偵測

Sensors detect the leading edge of pallets, polybags, blister packs, envelopes, tubes, and a wide range of difficult to detect targets.

![充填機上氣管識別有無[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![高速收縮膜套標[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/QS18VN6LLPQ5-Shrink-Sleeve-Bottle-Labeling.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)