飲料:初次包裝

飲料生產商的主要包裝從空的容器引入生產線上開始。在移動到主要包裝之前,容器會被沖洗乾淨、裝瓶並最終以非常高的速度加蓋。飲料裝瓶生產線的每個階段對設備和操作人員都構成獨特的挑戰。

初次包裝飲料應用

按機器類型查看應用程式

精選應用

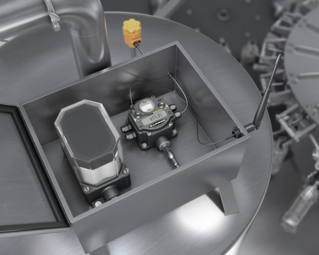

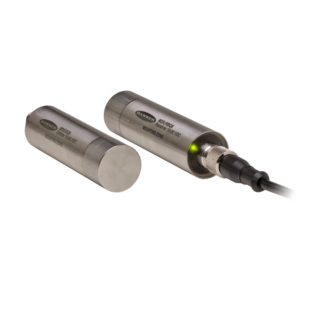

以無線解決方案替代集電環

滑環不斷運動,唯有不斷維修才能避免因正常磨損和碎屑造成的旋轉電氣連接退化。集電環故障導致生產停止,造成預料之外及昂貴的停機時間。DX80無線無線電提供了一種非接觸式解決方案,將感測器信號從裝填機碗內傳輸到控制面板。位於迴轉式裝填機上的無線節點可由電池供電,為感測器的無線安裝提供電力。DX80無線解決方案無需集電環,有助於減少停機時間和維修需要。

Clear Container Detection in a Clean-in-Place Rotary Filler

Track bottles as they move through the rotary filter.

識別瓶蓋的存在和高度

與Q4X和LED背燈配對的iVu Plus Gen 2視覺系統提供了可帶來可靠結果的解決方案。

瓶蓋分類檢測

Banner的R55F光纖感測器能夠檢測蓋子的存在,無論其顏色或尺寸如何 - 在採用各種瓶蓋和頻繁更換產線的產業中具有明顯優勢。在這種類型的應用中,光纖感測器用於辨別蓋子之間的長時間暫停,之後將向機器的操作人員發出產線堵塞的信號。光纖尺寸很精巧,並且可以很容易安裝在密閉和通常難以接近的空間中。

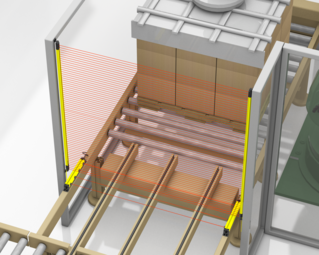

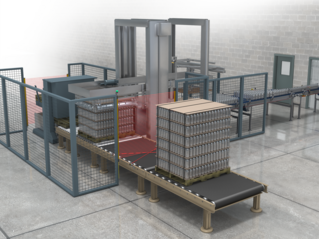

利用遮蔽功能提供裝卸空瓶棧板機械防護

LS 光幕是直觀、易於使用的安全裝置,可用於機器防護。專為生產線上各種危險的安裝環境所打造 LS-S 系列無需使用 PC 軟件、DIP 開關或其他設備即可快速、輕鬆地進行設定。

Non-Contact Fill Level Verification

Banner’s QS30H2O sensor is a specialized sensor developed to address challenges with sensing the presence of water and water-based liquids. The QS30H2O operates in a through beam sensing mode and the emitter uses a wavelength that is tuned to not pass through water. The high excess gain of the sensor makes it powerful enough to see through an assortment of plastic and glass containers. Two pairs of sensors can be utilized to determine that the fill level has met minimum but is not overfilled and wasting product. Apertures can be placed on the receiver end to minimize the beam pattern and increase accuracy of the application. This ensures products that do not meet fill level criteria are not processed or shipped.

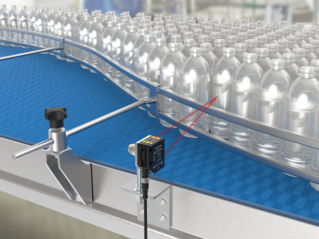

Detecting PET Bottles to Regulate Product Flow

Identifying gaps and accumulations to regulate product flow

單行裝瓶機的生產線內聚積

The Q5X laser sensor reliably detects when the staging area is clear of bottles and the system is ready for the next layer of containers, despite the transparency of the bottles and unstable signal.

在沖洗環境中偵測透明玻璃和塑膠聚酯瓶

Washdown environment, IP69K ratings required

![充填機上氣管識別有無[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![高速收縮膜套標[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/QS18VN6LLPQ5-Shrink-Sleeve-Bottle-Labeling.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)