Food: End of Line Packaging

End of Line Packaging in the Food Industry

At the end of the line, packed cases are palletized for shipping. The flow of packed cases to the palletizer and assembled pallets leaving for shipping must be regulated to prevent line slowdowns and stoppages. The presence and position of empty pallets being introduced to the system must be confirmed. Palletizers, conveyors and other equipment must be safeguarded to protect personnel from accident or injury.

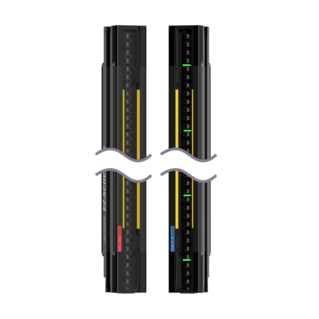

Banner products solve problems at the end of the line. Banner sensors featuring on/off delay timers monitor and regulate the flow of packed cases into the assembly and palletizing areas. Banner safety light curtains guard pallet in-feed and assembled pallet retrieval areas, and protect all access points to the palletizer. E-Stop buttons are deployed throughout the palletizing area and rope-pull switches along the conveyors enable staff to shut-down equipment in an emergency. Safety controllers simplify and centralize the management of all deployed safety devices.

End-of-Line Packaging Food Applications

View Applications by Machine Type

Palletizer

Banner's food packaging palletizer solutions include precision laser sensors and safety light screens for efficient operation and personnel safety.

Stretch Wrapper

Banner's food packaging stretch wrapping solutions feature laser sensors for accurate pallet positioning and roll monitoring, enhancing operation and safety.