Industrial Wireless

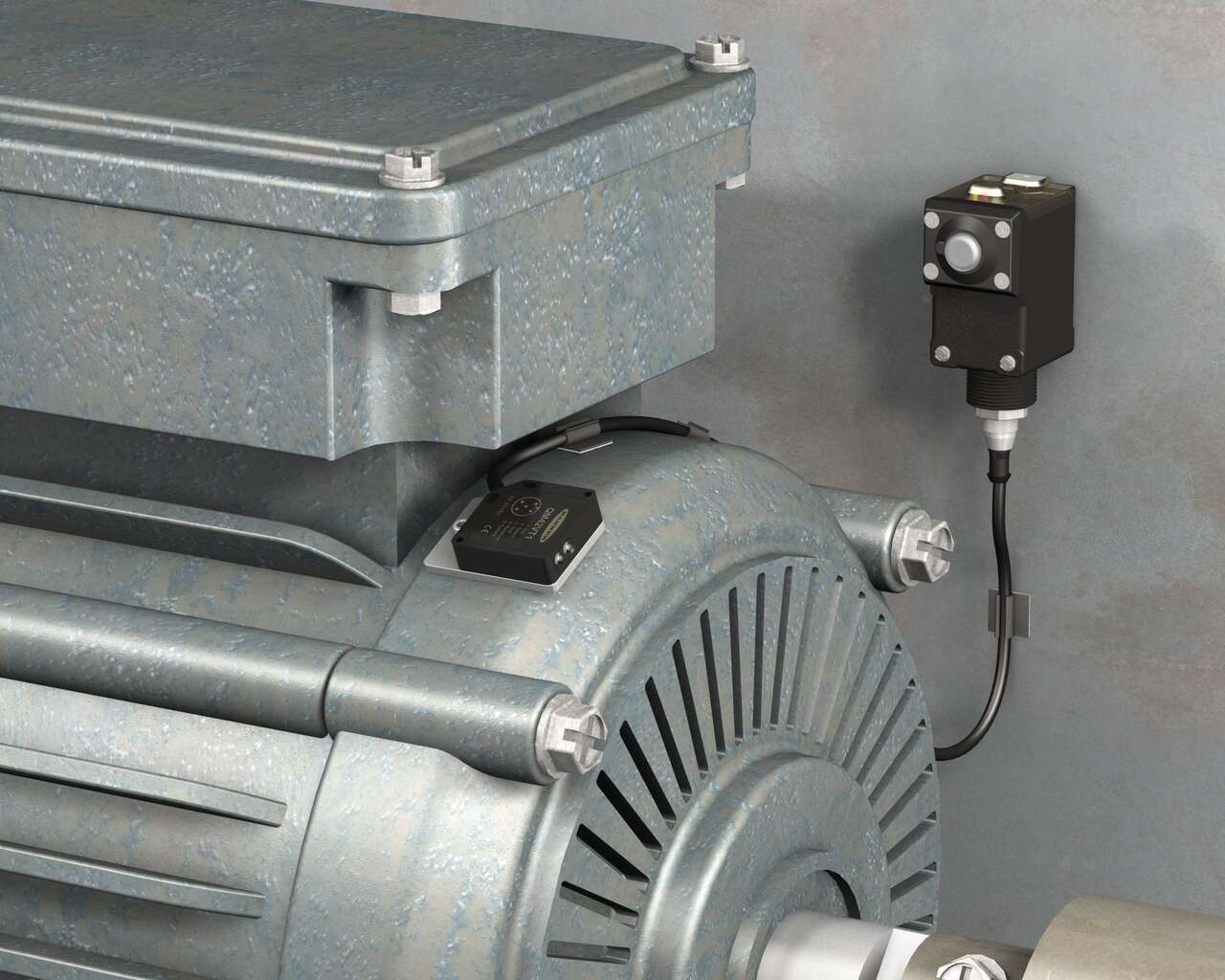

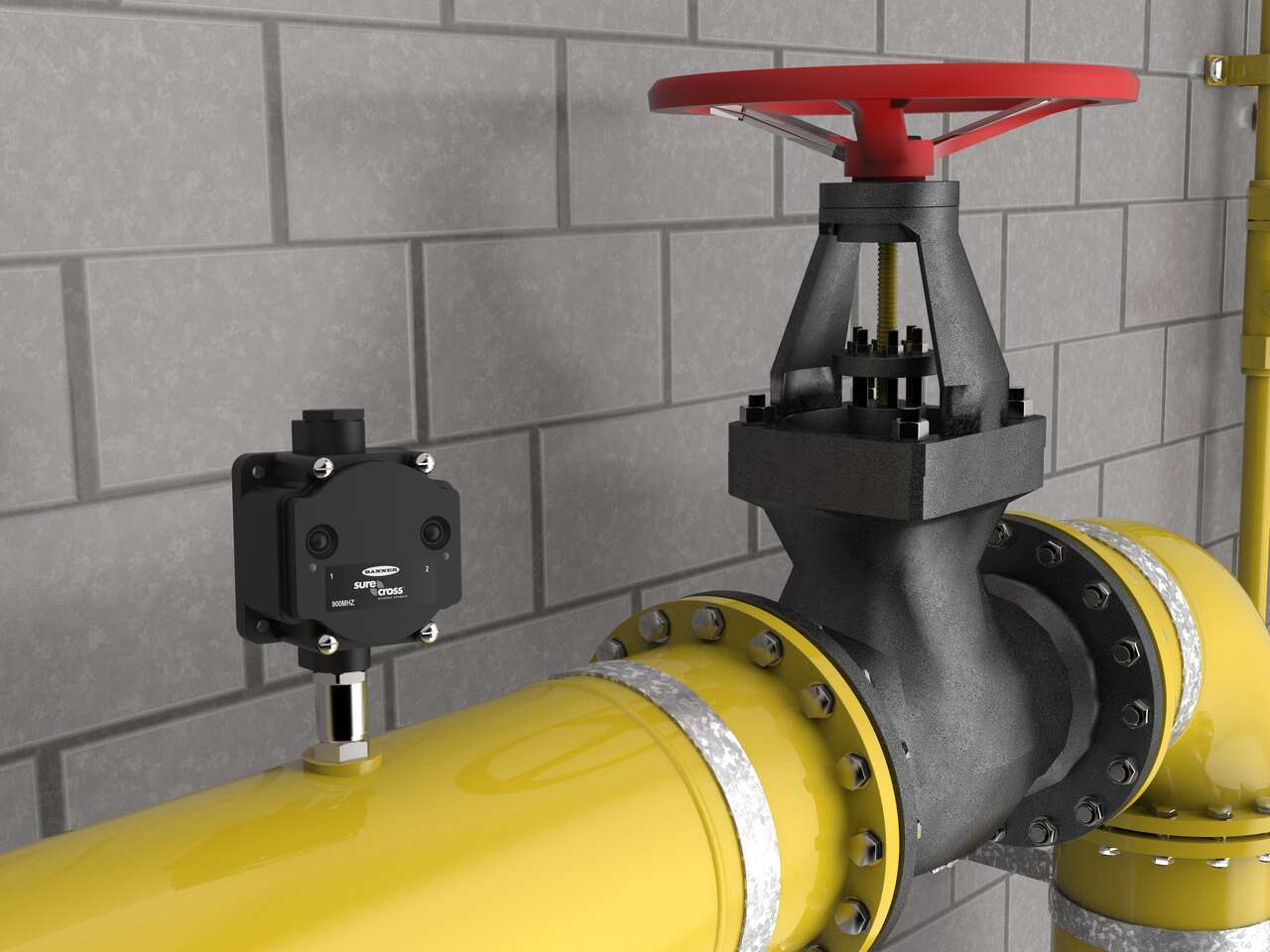

Wireless products from Banner connect remote assets with the people who manage them, enabling real-time monitoring and management of equipment and conditions.

Product Categories

-

-

Wireless Sensors

-

Operator Push Buttons and Switches

-

Indicators and Touch Buttons

-

Gateways & Controllers

-

I/O Radios

-

Data Radios

-

Wireless Product Software Tools

-

Cloud Data Services

-

Programming Software

-

Device Firmware

-

Predictive Maintenance

-

Overall Equipment Effectiveness (OEE)

-

Call for Parts

-

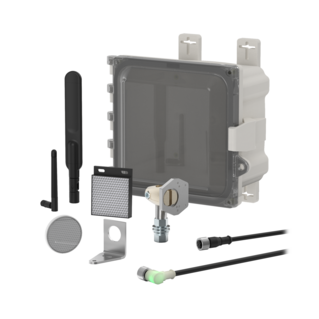

Wireless Accessories

-

Cellular Connectivity Products and Services

-

Programming Cables

-

Power Supplies

-

Reference Library

-

Manuals

-

DXM Programming and Configuration Examples

-

Cloud and Cellular Connectivity Services

-

Displays

-

Predictive Maintenance Product Selection

Monitoring Solutions

What is Industrial Wireless?

Industrial Wireless refers to the use of wireless communication technologies within industrial settings to connect devices, sensors, and systems. This approach eliminates the need for extensive cabling, enabling more flexible and efficient operations. Wireless solutions are particularly beneficial in environments where traditional wiring is impractical or cost-prohibitive.

What are the benefits of implementing Industrial Wireless solutions?

Implementing Industrial Wireless solutions offers several advantages:

Flexibility and Scalability: Wireless systems can be easily reconfigured or expanded to accommodate changing operational requirements without the constraints of physical wiring.

Cost Savings: Reducing or eliminating cabling can lower installation and maintenance costs, especially in large or complex facilities.

Improved Safety: Wireless technology minimizes the need for physical connections in hazardous areas, reducing potential safety risks.

Enhanced Data Accessibility:

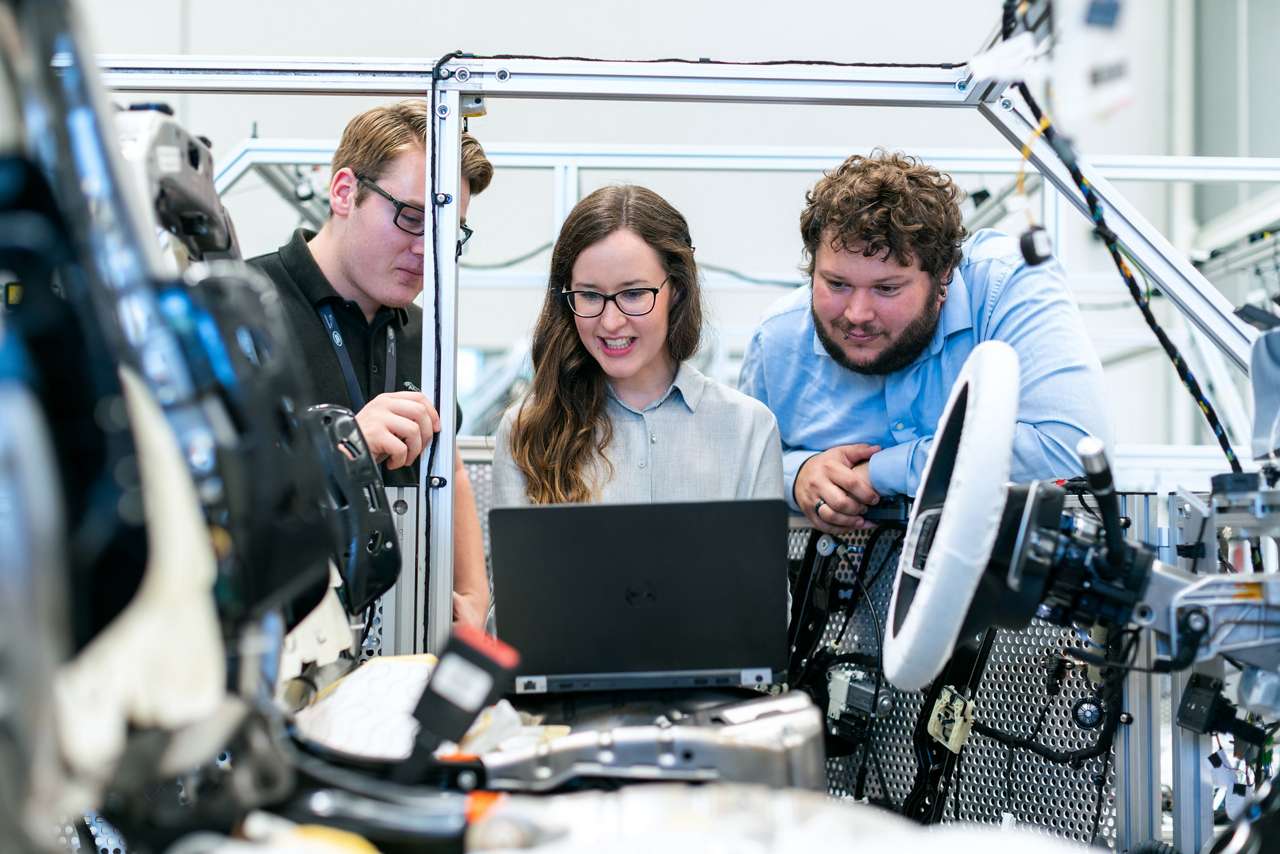

Wireless networks facilitate real-time data collection and monitoring, leading to more informed decision-making and improved process efficiency.

Trends

-

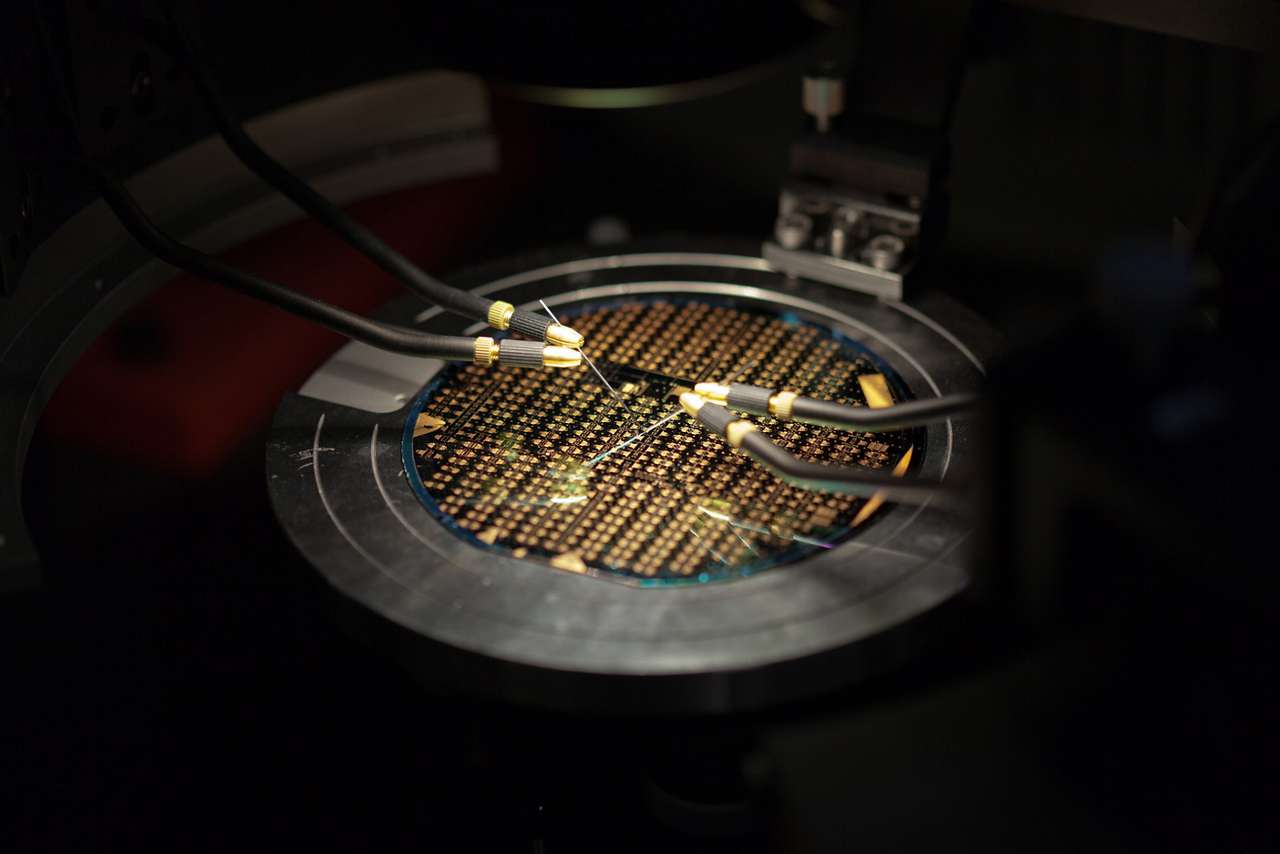

IIOT Innovations for the Data-Driven Factory

The Industrial Internet of Things (IIoT) describes the technologies that connect industrial field devices, such as sensors, to the cloud.

-

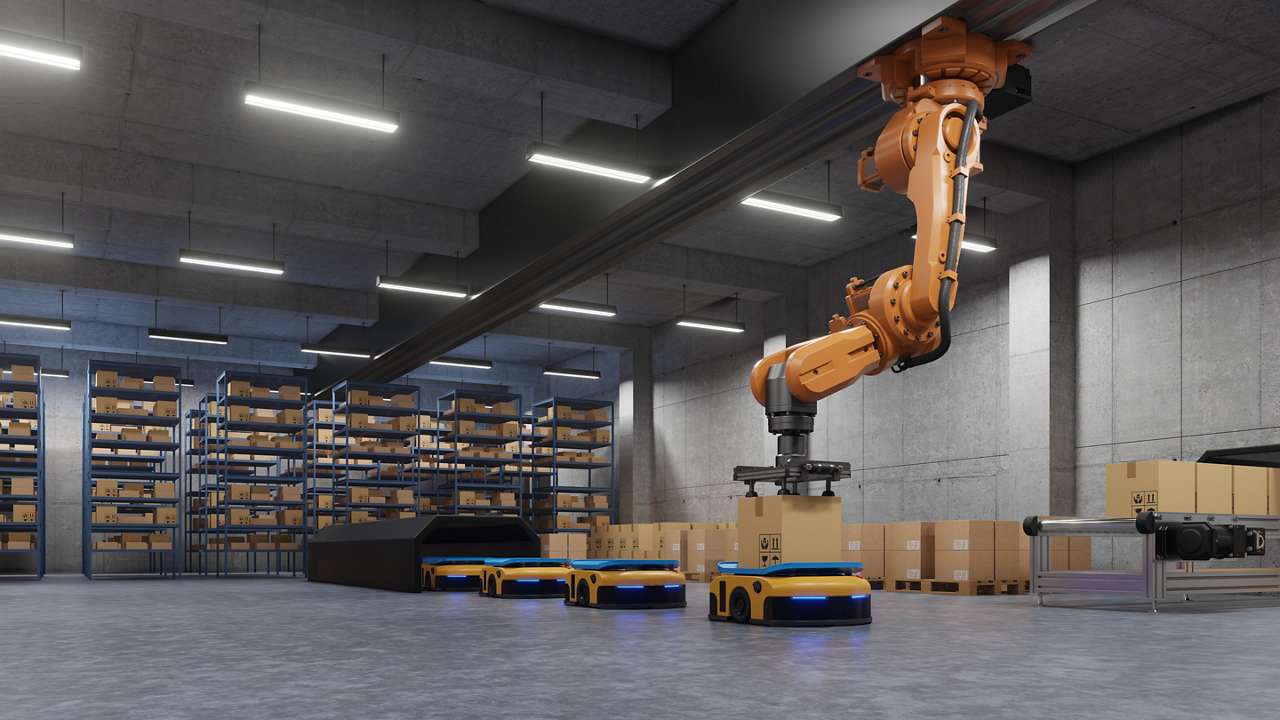

Predictive Maintenance and Condition Monitoring

Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

-

Remote Monitoring

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

-

Overall Equipment Effectiveness (OEE)

Remote monitoring capabilities provide data for OEE calculations, making it easier for manufacturers to identify and remedy causes of waste within their facilities.

-

Factory Communication

IIoT technologies enable better communication throughout the factory and streamline processes for machines and people alike.