Calculate Overall Equipment Effectiveness (OEE) with a Wireless Solution

Calculating Overall Equipment Effectiveness (OEE) can help you improve efficiency and productivity. With a wireless system, you can track uptime, validate throughput, monitor quality, and optimize your operation.

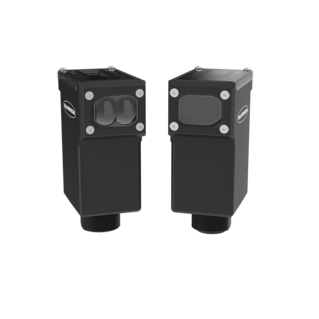

Related Products

Video Transcript

Your manufacturing operation is rolling as usual.

Everything seems to be running smoothly…and efficiently.

But are you sure you’re running as efficiently as you could be?

Do you know if there has been extended downtime during a changeover?

Do you know if your production line has slowed due to a shortage of parts?

You need a way to track the effectiveness of your entire process.

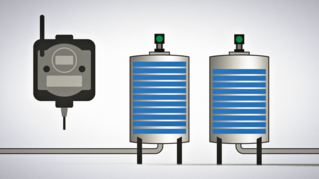

Track your uptime, validate your throughput, monitor your quality using Banner Engineering’s TL70 Wireless Tower Lights, Q45 part counting sensors, or other wireless sensors along with the DXM Wireless Controller to calculate your Overall Equipment Effectiveness.

Overall Equipment Effectiveness, or OEE, is a formula that calculates manufacturing productivity and enables you to identify causes of lost production and gain insight on process improvements.

OEE is a function of total production availability, performance, and quality.

Availability is the percentage of your equipment’s uptime, in respect to your total planned production time.

Performance is the percentage of your system’s speed compared to the ideal.

And, Quality is the percentage of good parts produced that pass your quality standard.

Multiply all of those measures and you get your overall equipment effectiveness percentage.

Banner’s TL70 Tower Lights with wireless connectivity can track uptime, downtime, and cycle times on your machines which enables you to calculate Availability and Performance.

Wiring a sensor into the tower light enables you to count good parts and track quality.

Banner’s Q45 Wireless photoelectric sensors count the in-feed and out-feed of machines and enable you to monitor machine states, production rates and count good and bad parts produced.

The production data is sent to the DXM Wireless Controller.

It can use the data to calculate OEE metrics, generate time stamped data logs, send data to the cloud, and generate text and email alerts.

Monitor throughput to increase uptime and cycle time.

Improve processes by identifying causes of lost production.

Collect OEE data and optimize your operation.