所有飲料業解決方案

-

Monitoring Pressure Levels on an Industrial Refrigeration System

Monitoring Pressure Levels on an Industrial Refrigeration System

Performance Series all-in-one wireless pressure sensors make it easy to monitor pressure levels in large and complex systems from any network-enabled location.

-

在沖洗環境中偵測透明玻璃和塑膠聚酯瓶

在沖洗環境中偵測透明玻璃和塑膠聚酯瓶

Detect clear glass and PET plastic bottles with various shapes and sizes. Washdown environment, IP69K ratings.

-

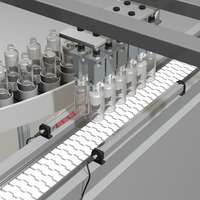

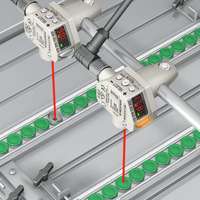

穩定偵側輸送機上的半透明塑膠瓶

穩定偵側輸送機上的半透明塑膠瓶

A machinery company needed a sensor able to consistently detect clear PET bottles at multiple points.

-

單行裝瓶機的生產線內聚積

單行裝瓶機的生產線內聚積

The Q5X laser sensor reliably detects when the staging area is clear of bottles and the system is ready for the next layer of containers, despite the transparency of the bottles and unstable signal.

-

Detecting PET Bottles to Regulate Product Flow

Detecting PET Bottles to Regulate Product Flow

Sensor solutions to detect translucent bottles in a range of shapes, sizes, colors and contours in a high-speed air conveyance system, identifying gaps.

-

對輸送帶上的多色亮面包裝進行計數

對輸送帶上的多色亮面包裝進行計數

Sensor solutions to verify packaging and count on conveyor. Foil and film packaging such as tea bags, multiple colors on packaging material.

-

Clear Glass Jar Detection for Food and Beverage Splash Zone

Clear Glass Jar Detection for Food and Beverage Splash Zone

Sensor solutions to detect clear glass jars to be filled with food in a strict sanitary environment where frequent, high-pressure washdowns and IP69K ratings.

-

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

Sensor solutions to detect bottle types with varying frequent in product changovers. High-speed labeler processing 800 bottles per minute, high temps.

-

Detecting Transparent Bottles in a Washdown Environment

Detecting Transparent Bottles in a Washdown Environment

Sensor solutions to detect accumulations to regulate line pressure where bottles vary in size, shape, color, and translucence and there is not a reflector.

-

半透明藥瓶的精確計數

半透明藥瓶的精確計數

Sensor solutions to count translucent and reflective glass vials in high-speed processes requiring quick response times and challenging light conditions.

-

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Sensor solutions to monitor a conveyor to ensure there are no stuck bottles when bottles are clear plastic in a large sensing area.

-

Detecting and Indicating the Presence of a Tipped Bottle

Detecting and Indicating the Presence of a Tipped Bottle

Sensor solutions to detect translucent bottles filled with clear liquid with a long bottling line with numerous areas to monitor.

-

Color Sensor Automates Sorting of Clear and Tinted Bottles

Color Sensor Automates Sorting of Clear and Tinted Bottles

Sensor solutions to detect plastic bottles varying in color and translucence where a high-speed system requires fast response times. Accurate sorting.

-

Detecting Tipped-Over Bottles on a High-Speed Bottling Line

Detecting Tipped-Over Bottles on a High-Speed Bottling Line

Detect translucent bottles varying by size, shape, color, and faceting. Large scale system of monitoring in multiple locations, quick clearance of tipped bottle.

-

Detecting Shiny, Unfinished Cans

Detecting Shiny, Unfinished Cans

Sensor solutions to detect small installation areas with multiple deployments on the line. Accurate detection of shiny cans supports smooth product flow.

-

Clear Container Detection in a Clean-in-Place Rotary Filler

Clear Container Detection in a Clean-in-Place Rotary Filler

Sensor solutions to detect bottle types vary in size, shape, color, translucence, and material. Equipment is regularly exposed to harsh washdown.

-

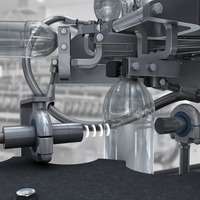

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Sensor solutions to detect bottle types vary by size, shape, color, contours, and translucence on a rinser where equipment is regularly exposed to washdowns.

-

Detecting Registration Marks on Labels

Detecting Registration Marks on Labels

Banner’s R58 high-speed, low-contrast expert registration sensor detects subtle registration marks on the labels as they pass at high speed—ensuring the label is cut at precisely the right moment for correct label placement. To accommodate frequent changeovers, the sensor is designed with LED color options—which automatically change depending which color best optimizes contrast.

-

Registration Mark Detection on a Labeler

Registration Mark Detection on a Labeler

Banner Engineering’s R58B Expert registration mark sensor confirms the registration mark’s position on the web. This allows the machine to make minor infeed adjustments to ensure the cut is properly placed and all labels are consistent and complete. If the labels are incorrectly cut they need to be removed from the bottling line creating costly downtime and waste. A quick and easy-to-use sensor is needed to dramatically improve throughput.

-

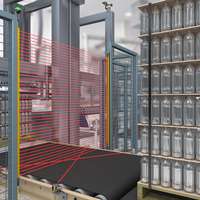

Safeguarding at Palletizer Station with Sticky Liquids Present

Safeguarding at Palletizer Station with Sticky Liquids Present

Safeguarding palletizer machines can be difficult because bottles are under a lot of pressure and can contain corrosive liquids such as soda or juice. Hygienic enclosures protect light curtains from corrosive liquids, meet sanitary requirements, and do not affect the performance of the sensor.

-

Safety Light Screens Guard Operators from Sweep Bar

Safety Light Screens Guard Operators from Sweep Bar

EZ-Screen LP 4型安全光幕為卸空瓶棧板機的操作人員提供針對掃測桿的運動的安全防護。為向個人提供針對掃除桿的安全防護,在光束之間提供14mm解析度,以防止進入和受傷。如果個人或物品觸及EZ-Screen的光束,則掃除動作將停止,以防止傷害。光幕的小型設計允許沿機器輕鬆安裝,不需要安裝PC或額外的設備。

-

Depalletizer Guarding with Muting Pair

Depalletizer Guarding with Muting Pair

我們的EZ-SCREEN遮蔽光幕的設計允許棧板進出產線,同時使危險區域得到安全防護,當有人員進入該區域時關閉機器。EZ-SCREEN上的遮蔽功能允許產線移動棧板滑軌,不需關閉或重啟機器,而關閉或重啟機器通常會降低生產線的生產速度及效率。在飲料業中,有些機械組裝過程要順利運行,必須使用遮蔽功能選項。

-

Safeguarding the Palletizer and Stretch Wrapper

Safeguarding the Palletizer and Stretch Wrapper

為裝運機和捆包機周圍的區域提供安全防護可能很困難,因為它涉及多重危險。可擴展的安全控制器可以幫助管理與裝運機和捆包機相關的危險,同時確保有效的安全防護過程。

-

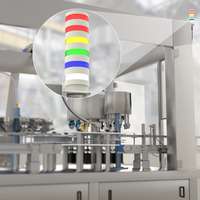

Dynamic Maintenance Indication on a Beverage Line

Dynamic Maintenance Indication on a Beverage Line

TL50 Pro tower lights clearly informs operators that maintenance procedures are in progress with advanced action mode animation.

-

偵測容器內的液體

偵測容器內的液體

Banner combined the technology of WORLD-BEAM QS30 opposed mode sensors, which provide high excess gain, with a 1450 nm infrared sensing beam—specially tuned to an absorption band of water, to create the QS30H2O Water Sensor. In this application, the powerful sensing beam of the QS30H2O will burn through the opaque plastic of the container. At 1450 nm, water absorbs 1,000 times the energy of alternative wavelengths, preventing the beam from burning through the liquid within the container.

-

Level Monitoring for Washdown Environments

Level Monitoring for Washdown Environments

Banner’s U-Gage QT50U ultrasonic sensor excels at the most challenging level applications, bouncing sound off any solid surface—even those that may vary in consistency or contrast. The sensor is available with a Teflon-coated transducer cover, making it resistant to harsh chemicals and suitable for the food and beverage industry. Ultrasonic sensors are able to provide accurate monitoring of pump-controlled tanks by sending a continuous signal to measure the current tank depth.

-

Level Monitoring On Rotary Filler System

Level Monitoring On Rotary Filler System

Banner’s SureCross wireless system can easily transmit temperature, pressure and fill levels to a local PLCs. The wireless system will seamlessly alert operators if bottling is occurring below the desired fill level. This helps prevent errors and leads to greater consistency in bottled beverages. Consistent fill levels mean no recalls—and no wasted products. Using a wireless system also eliminates the need for slip rings on the rotary filler, which in turn reduces maintenance costs.

-

Remote Fill Level Indicator

Remote Fill Level Indicator

A brew pub uses EZ-LIGHT indicator lights as a remote display of the status of the levels in the brew tanks. The indicators are connected to ultrasonic sensors within the tanks that cannot be monitored easily.

-

Tank Level, Pressure, and Temperature Monitoring

Tank Level, Pressure, and Temperature Monitoring

To wirelessly monitor and report level, pressure, and temperatures in the rotary fillers, each rotary filler was equipped with a FlexPower Node and DX81P6 6-pack battery supply. The FlexPower Node had two 0–20 mA analog inputs and one thermistor input while the battery pack supplied power to the Node and sensors for more than a year. A level probe, pressure transmitter, and thermistor (not supplied by Banner) were connected to the FlexPower Nodes and installed in the rotary tanks.

-

Non-Contact Fill Level Verification

Non-Contact Fill Level Verification

Banner’s QS30H2O sensor is a specialized sensor developed to address challenges with sensing the presence of water and water-based liquids. The QS30H2O operates in a through beam sensing mode and the emitter uses a wavelength that is tuned to not pass through water. The high excess gain of the sensor makes it powerful enough to see through an assortment of plastic and glass containers. Two pairs of sensors can be utilized to determine that the fill level has met minimum but is not overfilled and wasting product. Apertures can be placed on the receiver end to minimize the beam pattern and increase accuracy of the application. This ensures products that do not meet fill level criteria are not processed or shipped.

-

Clear Material Loop Control

Clear Material Loop Control

Banner’s T30UX ultrasonic sensor is the perfect sensor for detecting clear material for loop control because it uses sound rather than light, which makes it more accurate and cost-effective for this specific application. Although the material is clear, it presents a solid surface for an ultrasonic sensor to bounce a sound wave. The T30UX has a more accurate transducer, a smaller dead zone and minimum distance compared to other sensors that can be used for clear material detection.

-

Roll Diameter on Labels

Roll Diameter on Labels

In the beverage industry, labels need to be applied to the bottles quickly and without error to keep production levels high. Accurately monitoring the thickness on a spool of labels and controlling the unwinding speed is very important for the process to run smoothly. A solution is needed that can accurately supervise and report the material levels on a spool in order to prevent it from running out during the manufacturing process and delaying production.

-

食品箱上的日期/批號驗證

食品箱上的日期/批號驗證

Banner堅固的PresencePLUS P4密封式OMNI視覺感測器適用於日期/批號的驗證,因為它使用光學字元驗證/OCV檢查,以確保正確的日期和批號被清晰列印。這款感測器的外殼的防護等級為IP68,是食品和飲料應用的理想之選,因為它可以承受嚴酷的沖洗環境。P4 OMNI感測器透過驗證紙盒的邊緣,輕鬆找到需要進行日期/批號檢測的紙盒的相應區域。Wi

-

在困難位置的小零件檢測

在困難位置的小零件檢測

Banner Engineering的iVu視覺感測器在繁忙的裝瓶線上檢查存在的排氣管和伸縮墊圈。它使用50毫米的C型支架鏡頭來擴展感測器的工作範圍,以避免與噴霧和液體接觸。

-

偵測防偽封膜的位置和有無存在

偵測防偽封膜的位置和有無存在

Banner iVu TG視覺感測器具有多點檢測功能,是偵測和評估防偽封膜的位置的理想選擇。在此應用中,防偽封膜應位於瓶子的瓶蓋和頸部周圍。認為位置太高、太低或完全缺失的密封是不可接受的。透過多點檢測,iVu TG視覺感測器可以同時偵測防偽帶缺失和位置不佳。

-

收縮膜標籤有無且標籤正確檢測

收縮膜標籤有無且標籤正確檢測

P4 OMNI視覺Camera正好位於離開標籤機的瓶子的後面,標籤機確保標籤的呈現將以可重複的方式進行,因此可以與存放的影像進行比較。P4 OMNI密封的防護等級為IP68,採用鍍鎳鍍鋅外殼。

-

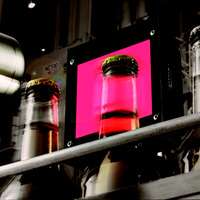

利用PresencePlus進行高速瓶子檢測

利用PresencePlus進行高速瓶子檢測

要快速驗證啤酒瓶被灌装到正確的水平位置並且瓶蓋已經正確對齊,使用高速PresencePLUS P4視覺感測器來定位瓶子並驗證瓶子的液位高度和瓶蓋位置。這有助於消除對多個感測器的需求,同時準確偵測瓶蓋的存在並監測灌裝液位。紅色背燈提供與瓶子之間的強烈對比、擴大瓶子的特徵,以便於偵測。

-

狹窄區域中的瓶蓋檢測

狹窄區域中的瓶蓋檢測

堅固耐用與耐環境外殼的World-Beam Q12感測器使用定距離技術檢測瓶蓋,以忽略蓋顏色變化。由於生產線上有許多類型的瓶子和產品,感測器應忽略瓶蓋尺寸,無論是瓶蓋是25 mm還是50 mm,這一點很重要。使用同樣的定距離技術,Q12很容易在檢測瓶蓋是否存在時忽略瓶蓋的顏色和尺寸變化。

-

日期/批號有無或缺失偵測

日期/批號有無或缺失偵測

An SLM series slot sensor and an iVu Series vision sensorare used to detect bottles passing on the line and to verify that date/lot codes have been correctly printed onto the bottles.

-

充填機上氣管識別有無[成功案例]

充填機上氣管識別有無[成功案例]

迴轉式裝填機將啤酒分裝瓶中,而裝填機則以每分鐘高達900瓶的速度行進。該公司需要一個解決方案,能偵測通氣管上的伸縮墊片以及鬆動或脫落的管子。然而,迴轉式裝填機的動作和潮濕的沖洗環境,使得互相貼近的部署變得很困難,遠距解決方案所需的範圍可能有損檢查的可靠性。

-

高速收縮膜套標[成功案例]

高速收縮膜套標[成功案例]

一家標籤設備的主要製造商提供高速收縮套標機,該機每分鐘可處理800瓶。為將機器的潛在效能提升到最高,該公司希望安裝一種感測器,能夠進行一致的高速裝瓶偵測和輸出。

-

進料機裝置中的零件偵測

進料機裝置中的零件偵測

在本圖中,蓋子已被載入進料器裝置中,該裝置則將待定位的零組件保持一致定向,供稍後製造過程中瓶子應用所用。Banner QS30AF是該應用的理想感測解決方案,在蓋子從裝置中移出時,可用於監測其供應量。

-

以無線解決方案替代集電環

以無線解決方案替代集電環

滑環不斷運動,唯有不斷維修才能避免因正常磨損和碎屑造成的旋轉電氣連接退化。集電環故障導致生產停止,造成預料之外及昂貴的停機時間。DX80無線無線電提供了一種非接觸式解決方案,將感測器信號從裝填機碗內傳輸到控制面板。位於迴轉式裝填機上的無線節點可由電池供電,為感測器的無線安裝提供電力。DX80無線解決方案無需集電環,有助於減少停機時間和維修需要。

-

透過視覺指示來指明安全條件

透過視覺指示來指明安全條件

為了維護飲料行業的高效生產線,應立即通知任何安全問題,這一點至關重要。使用視覺和聽覺指示來識別安全問題可以幫助員工快速找到並糾正錯誤 - 以及時將系統恢復到正常運行狀態。

![高速收縮膜套標[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/QS18VN6LLPQ5-Shrink-Sleeve-Bottle-Labeling.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)