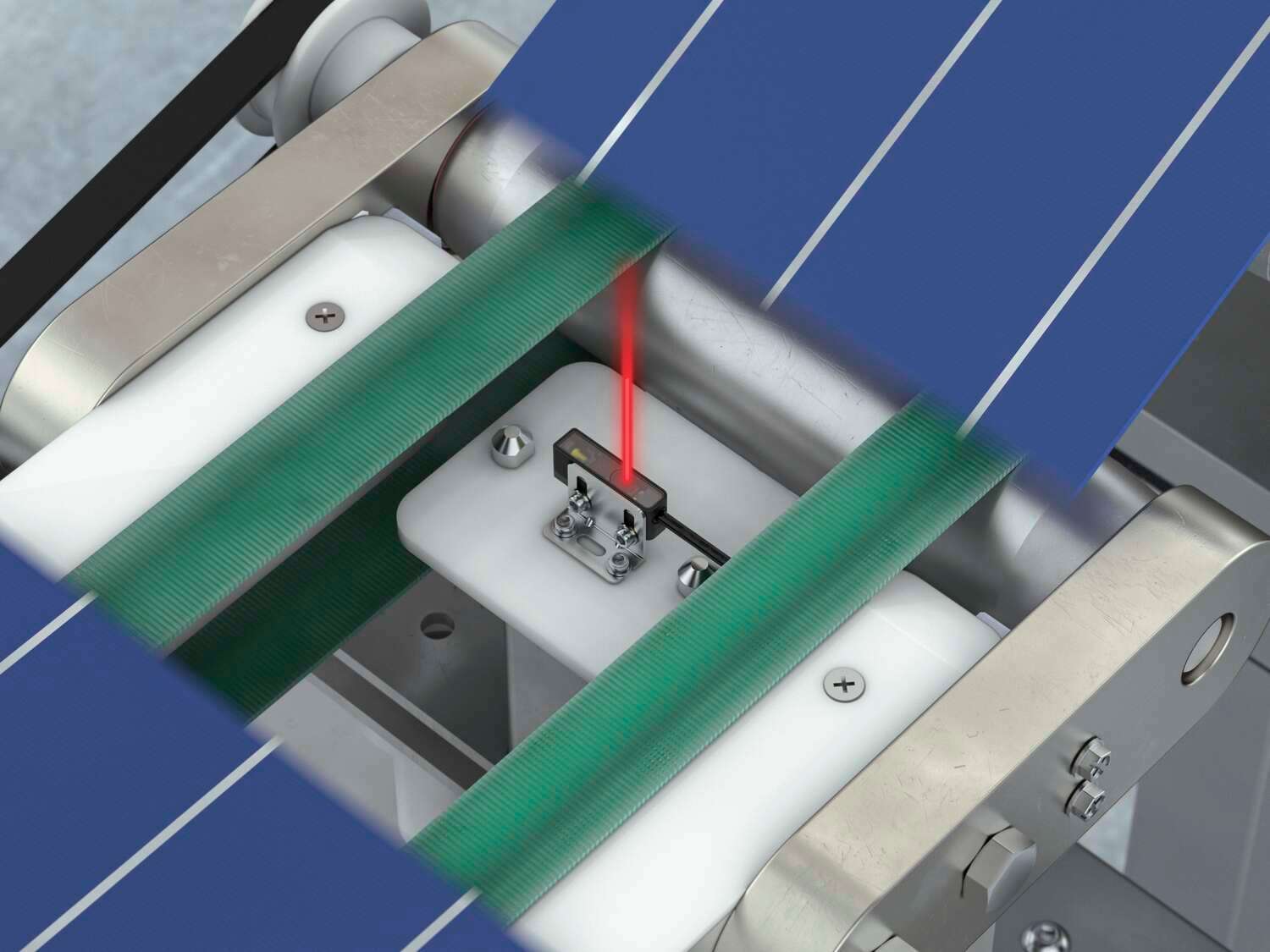

Dark Wafer Presence Detection

Challenge

In the manufacturing process for solar panels, there tends to be limited space to mount sensors for detecting the presence of silicon wafers for screen printing. Screen printing adds minute conductive lines that collect electrons converted from photons and transfer them to the electrical circuitry system. Because solar panels are designed to absorb as much light as possible, many sensors’ emitted beams are insufficient to detect the targets.

Solution

Q2X sensors are built into compact housings for installation in tight spaces, including wafer screen-printing machines. Once installed in these machines, adjustable-field Q2X sensors use high excess gain to detect the presence of dark wafers on conveyors. The signal feedback from the sensors will tell the machines when to lift and load wafers that have no conductive lines. Those wafers are then sent to printing machines to be printed with conductive silver paste. Adjustable-Field Q2X sensors have a small minimum object separation, so additionally they can be used to detect when wafers are lifted to a precise height, triggering the next wafer to move forward into position.