Level Measurement

Accurate Level Measurement Saves Costs

Accessing accurate level data from containers, hoppers, and tanks is critical to managing inventory, securing contents, assuring quality and safety, and saving costs.

Banner solutions for measuring and monitoring fill and material levels are available in a range of sensing technologies to optimize detection for each unique target and environment.

Used in combination with our wireless products, these solutions provide accurate, real-time data from assets deployed in remote and hard-to-access areas.

Reliable level detection is critical for a wide range of applications. For example, a dependable level measurement solution can:

- Ensure material is not wasted in spills due to overfill, which saves time and costs.

- Protect equipment from damage due to underfilling

- Prevent unplanned downtime and keeps processes moving along smoothly by predicting when containers will run out and enabling them to be refilled in a timely manner.

- Ensure customers and end users receive the correct amount of product, which improves customer satisfaction.

However, level measurement can be challenging due to the wide variety of materials, the location of containers, mounting contstraints, and more.

From precise measurement solutions to wireless solutions for remote tank level monitoring, Banner Engineering offers a variety of technologies to match your level measurement application. See a few examples below, or contact us to discuss your specific application.

Measure Level of Material in a Stack

- An accurate sensor is needed to monitor the stack height of the carton blanks in the magazine to ensure the stack is not empty and prevent downtime.

- A smart sensor, like the Q4X sensor, can accommodate changes in carton size and machine speed to help reduce downtime for setup and changeovers.

- The analog output provides a real-time gauge of the stack height. This allows the cartoner machine to have several “call for parts” set points without having to manually move the sensor.

- With exceptional linearity and a four-digit display, the Q4X sensor provides real-time feedback with an analog (V or mA) or distance (mm) readout.

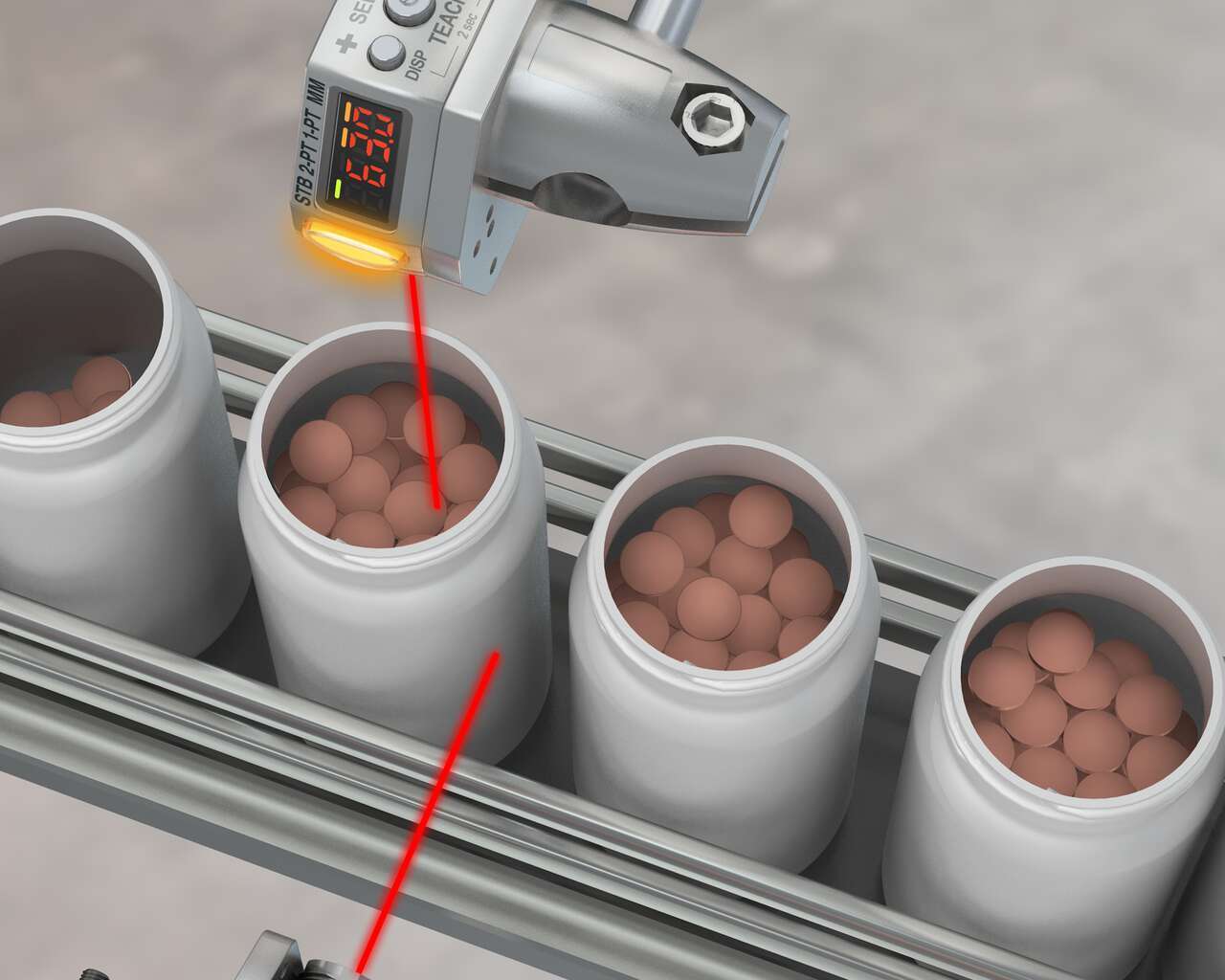

Monitor Level of Material in a Hopper

- For long-range level detection applications, an LTF Series laser measurement sensor can be installed up to 12 meters away from the target

- At this distance, the sensor will not interfere with system operations or come into contact with the equipment or process.

- The sensor features high excess gain, superior signal control and automatic adaptive laser power control for reliable detection, regardless of surface color or reflectivity.

- The exceptional linearity, repeatability and resolution of LTF series sensors ensure tremendous accuracy in measuring the distance from the sensor to the material in the hopper.

- The laser sensor can be paired with a TL50 Pro tower light to provide dynamic status indication of hopper fill level, for monitoring at a glance even from a distance.

Monitor Liquid Levels in Tanks

- Storage tanks, totes, and containers can be found in a wide variety of environments, from indoor or outdoor installations to above or below ground deployments.

- Properly monitoring and managing levels inside these tanks can help increase productivity and profitability.

- A wireless ultrasonic sensor uses sound waves to detect objects, for a non-contact level measurement solution.

- Ultrasonic sensors are also immune to target color, reflectivity, or transparency.

- Wireless communications open up additional benefits including saved time and costs, real-time remote monitoring, and adaptability to meet changing requirements.

Rugged Laser Distance Sensor

Versatile, rugged laser distance sensors offering superior performance and capable of detecting sub-millimeter changes in distance.

- Discrete, analog (0 to 10 V or 4 to 20 mA), clear object, and IO-Link models available

- Reliable sensing range from as close as 25 mm and as far as 610 mm

- Detects across a variety of target colors, materials and surfaces based on distance

- Dual teach mode (intensity + distance) is ideal for error-proofing applications and enables clear object detection with no retro-reflector required

- Robust housing rated to IP69K with FDA-grade stainless steel

Laser Measurement Sensor

LE 시리즈 선형 어레이 기술을 통해 감지 대상의 색상이나 광택에 관계없이 뛰어난 성능과 해상도를 제공합니다.

- 즉시 사용할 수 있음

- 직관적인 2줄, 8자 디스플레이로 조정이 쉬움

- 선형 어레이가 까다로운 대상에 대해 반복성과 정확성 제공

- 작은 스포트 크기 및 쉬운 정렬을 위한 가시 레이저

- IO-LINK 모델 사용 가능

LTF Series

Long Range Laser Measurement Sensor

고성능 LTF 시리즈 센서는 최대 24미터의 거리에서 직선 또는 비스듬하게 색상, 재질 또는 광택에 관계없이 대상을 감지합니다.

- 측정 및 감지 응용 분야를 위한 아날로그 및 이산 또는 이중 이산 출력

- 동급 최상의 범위, 반복성 및 정확도가 조합되어 신뢰성 높게 대상 감지 및 정확한 거리 측정 가능

- 쉬운 설정, 문제 해결 및 실시간 거리 측정을 위한 2줄, 8자의 디스플레이 및 푸시 버튼 프로그래밍

- 내구성이 뛰어난 IP67 하우징, 다양한 온도에서 높은 주변광 내성 및 안정된 성능으로 까다로운 환경에서도 안정적인 성능 제공

- 지연 타이머, 고급 트리거 측정 모드 및 크로스토크 방지 등의 고급 옵션

- 원격 구성 및 모니터링이 가능하고 배선, 예방 유지 보수 및 장치 교체를 단순화하는 IO-Link 통신 기능이 있는 모델에 사용 가능

- 원격 센서 디스플레이(RSD)로 원격 프로그래밍 및 모니터링이 가능합니다.