Error Proofing and Poka Yoke

Prevent Errors in Lean Manufacturing Environments

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line.

Another word for error proofing is poka-yoke (which is Japanese for avoiding inadvertent errors). Poka-yoke design is often used to avoid human error by either warning operators when they are about to make a mistake or preventing them from making a mistake at all. Poka-yoke design makes it virtually impossible for an operator to complete an action incorrectly.

Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

Quality Inspection at the Source

Error-proofing takes quality control to the next level by checking for mistakes and defects before those defects can proceed to the next stage of production. Preventing defects from proceeding from one stage of production to the next avoids wasted time and resources spent working on defective parts.

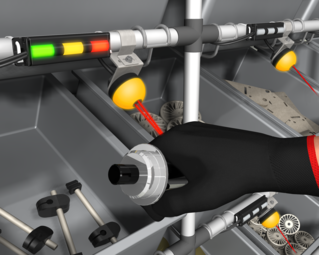

In manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

Meanwhile, in more automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Banner Engineering provides sensor, vision, and light-guided solutions for error proofing to help manufacturers increase efficiency, improve quality, and reduce downtime. Keep reading to learn more, or contact us to discuss your specific application.

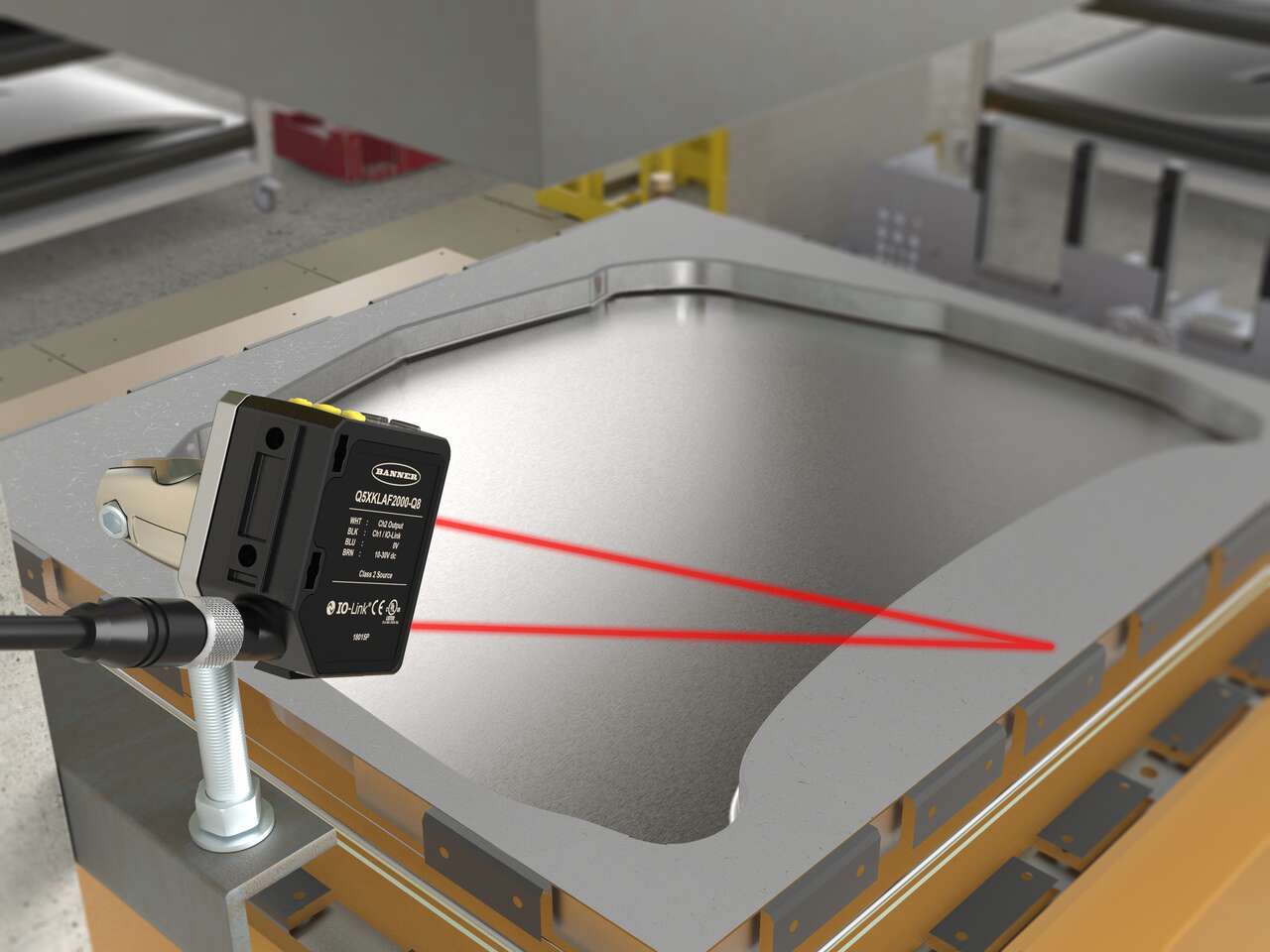

- Laser measurement sensors are often a reliable solution to error-proofing applications.

- Laser sensors from Banner detect and measure the most challenging targets, for error-proofing solutions manufacturers can trust.

- For example, in metal stamping applications, it is critical to ensure that metal sheets are properly indexed on the press before stamping to avoid material waste and damage to the press die.

- The Q5X Series laser sensor reliably detects reflective targets even at an acute angle.

- The press cannot operate until the sensor verifies the leading edge of the material and confirms that the metal sheet is both present and properly indexed.

- In some applications, a vision solution can be an excellent choice for error-proofing.

- For example, in automotive assembly, interior trim pieces are interchangeable, but vary in color, making it easy to install the wrong piece. As assembly progresses, correcting errors becomes more difficult.

- An iVu Color vision sensor verifies that trim colors match the build order for a vehicle.

- If an error is detected (the wrong color trim is placed), the error must be remedied before the automotive assembly can proceed to the next step.

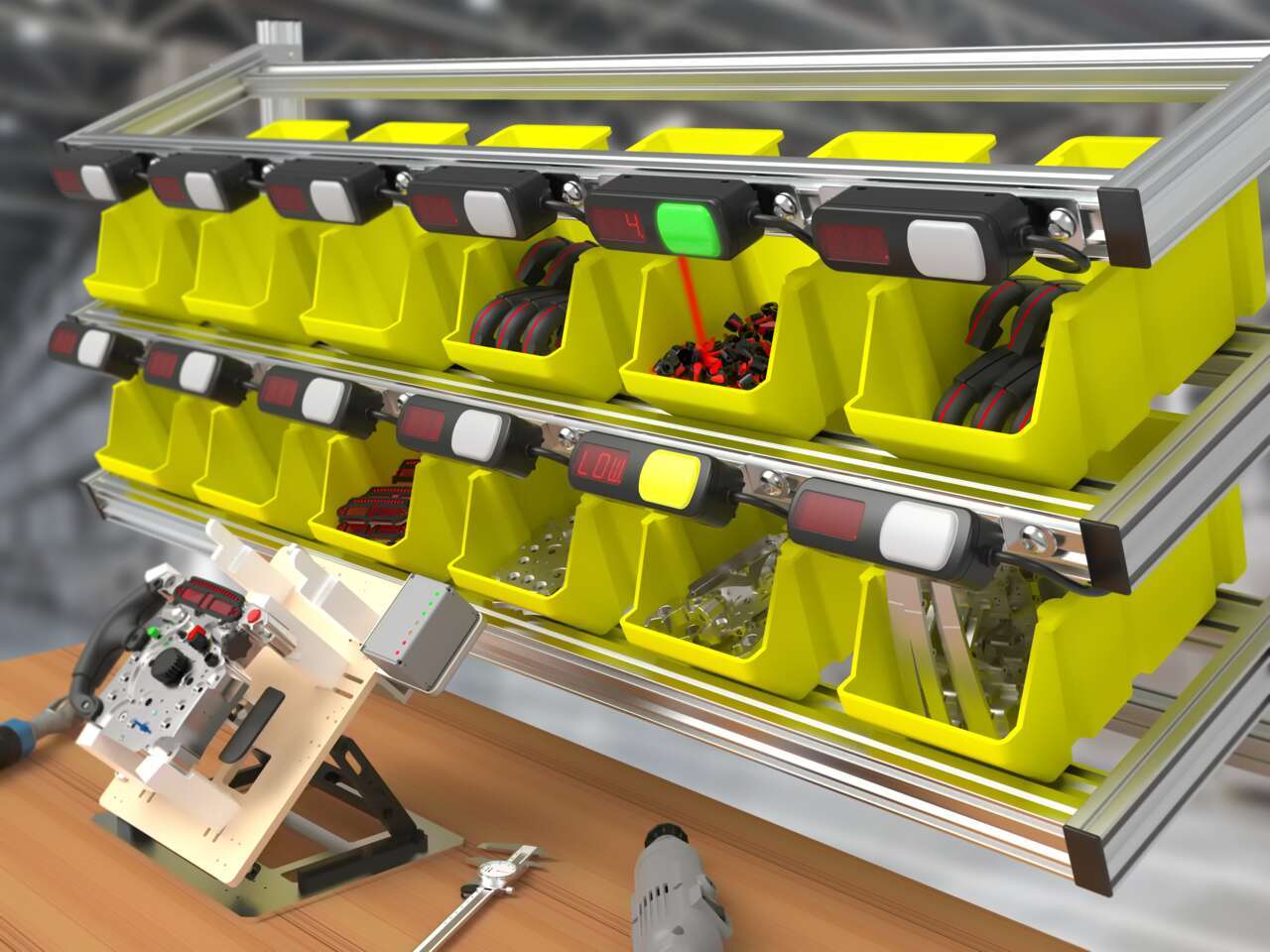

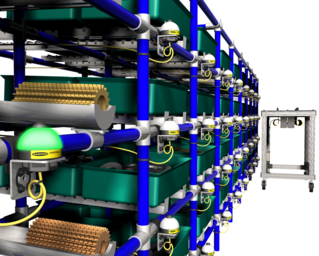

- Perhaps one of the most common error-proofing technologies in assembly processes is light-guided picking, also known as pick-to-light.

- Pick-to-light devices use colored LEDs to visually guide assemblers to pick the correct parts, in the right quantities, and in the proper sequence.

- This reduces the risk of human errors and speeds up build times to ensure high quality while maximizing productivity.

Rugged Laser Distance Sensor

Versatile, rugged laser distance sensors offering superior performance and capable of detecting sub-millimeter changes in distance.

- Discrete, analog (0 to 10 V or 4 to 20 mA), clear object, and IO-Link models available

- Reliable sensing range from as close as 25 mm and as far as 610 mm

- Detects across a variety of target colors, materials and surfaces based on distance

- Dual teach mode (intensity + distance) is ideal for error-proofing applications and enables clear object detection with no retro-reflector required

- Robust housing rated to IP69K with FDA-grade stainless steel

Vision Sensor

iVu 및 iVu 컬러 이미지 센서는 부품의 유형, 크기, 방향, 모양, 위치 및 색상 또는 색상 변동을 모니터링하는 데 사용됩니다.

- 하나의 패키지에 카메라, 컨트롤러, 렌즈 및 조명이 모두 포함되어 있는 일체형 솔루션

- Vision Manager PC 소프트웨어, 온보드 터치스크린 디스플레이 또는 원격 터치스크린을 사용하여 몇 분 안에 구성

- 다양한 그레이스케일 또는 색상 도구를 사용하여 여러 지점 검사

- 통합형 링 조명(빨간색, 파란색, 녹색, 흰색, 적외선 또는 UV)이 달린 작지만 견고한 IP67 하우징

- 응용 분야의 유연성을 극대화하기 위한 교체 가능한 렌즈(C-마운트 포함)

- EtherNet/IP™, Modbus/TCP, PROFINET®, PCCC 및 Serial RS-232

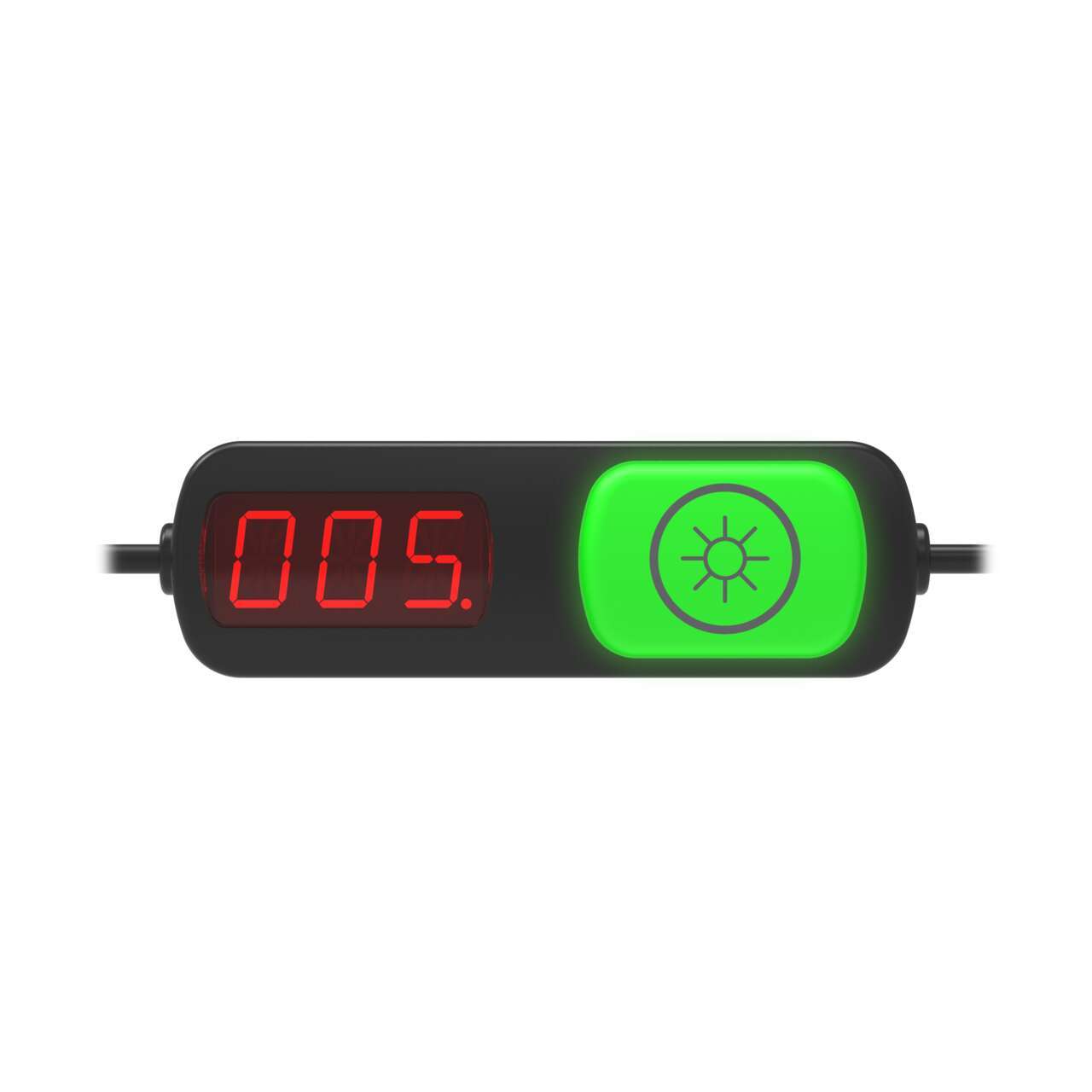

PTL110 Series

Scalable, Versatile Pick-to-Light Devices

PTL110 Pick-to-Light 장치는 터치 버튼, 광학 센서 및 세 자리 디스플레이를 위한 옵션을 갖춘 다기능 표시등으로, 직렬로 연결되어 강력한 피킹 시스템을 구성합니다. 빠른 응답 시간과 유연한 설치 옵션을 갖춘 PTL110 시스템은 피킹, 키팅 및 관련 응용 분야에서 속도, 생산성 및 품질을 향상시킵니다.

- 광학 터치 센서 기능을 갖춘 모델로 제공됩니다.

- 선택적 3자리 영숫자 디스플레이를 사용하면 부품 개수를 표시하거나 다른 지침을 제공할 수 있습니다.

- M12 커넥터를 사용하면 추가 케이블이 없어도 여러 장치를 안전하고 빠르게 설치할 수 있습니다.

- 이 표시등은 14가지 색상 및 여러 애니메이션 기능을 제공해다양한 상태를 구분합니다.

- PICK-IQ™는 여러 장치를 폴링하는 데에서 발생하는 일반적인 지연을 단축하기 위해 공통 ID를 사용하도록 특별히 개발된 Modbus 호환 직렬 버스 프로토콜입니다.

- DXM700 무선 컨트롤러와 연결해 카트 및 이동식 피킹 스테이션에 배치할 수 있습니다.