Vehicle Detection at Loading Docks

Improve Productivity and Efficiency

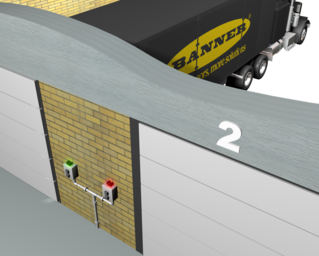

Vehicle detection at a loading dock can be used to quickly identify available bays, facilitate fast load and unload times by alerting staff when trucks are present, verifying vehicles are in the correct position before opening doors, and more.

These capabilities help imrpove productivity and efficiency at manufacturing facilities and warehouses.

Detecting vehicles at a loading dock can be difficult because of unpredictable weather and environmental changes. Sensors installed here are exposed to the elements and need to be able to withstand fluctuations in weather and ambient light.

In addition, truck surfaces are made of a variety of materials and come in a range of colors and sizes, which can be challenging for traditional sensors to detect reliably. A solution is needed that consistently detects trucks regardless of the color, reflectivity, or size of the vehicle.

There are a variety of technologies that can be used to solve these applications, including radar sensors, ultrasonic sensors, and fully wireless solutions. In addition, pairing a vehicle sensing technology with bright indicator lights helps staff quickly react when trucks arrive.

Application: A reliable solution is needed to detect presence the of large trucks at a loading dock even in harsh conditions and verify that trucks are in the correct position before the door is opened. to ensure the safety and security of the facility.

Solution: A radar sensor, like the QT50R high sensitivity radar sensor, uses Frequency Modulated Continuous Wave (FMCW) radar to ensure reliable detection of moving or stationary targets regardless of environmental conditions. Radar is an ideal solution for detecting large targets like semi trucks in outdoor environments.

Benefits: Radar technology is unaffected by weather conditions such as wind, rain, ambient light, etc. A radar sensor with a rugged housing built for outdoor use, reducing the need for frequent maintenance or replacement.

Application: A loading dock at a manufacturing facility needs to detect shipping trucks to improve dock efficiency. The commotion of a manufacturing plant can make it difficult to quickly capture the attention of staff when a vehicle arrives.

Solution: A wireless ultrasonic sensor uses sound waves to detect when trucks arrive at the warehouse loading dock. A high-visibility tower light, like the TL70 tower light with audible alarm, both visually and audibly alerts staff that the vehicle has arrived and is ready to be loaded or unloaded.

Benefits: Pairing wireless sensors and indicators together makes it easy to quickly and clearly communicate when vehicles arrive at the dock. Rugged sensors from Banner can withstand harsh outdoor conditions.

Application: Errors and delays at the loading dock can cause problems throughout the supply chain. Identifying available bays on the loading dock and directing staff to the correct bay when a delivery has arrived can improve turnaround time and reduce errors. Performance data from the loading dock can help supervisors make more informed decisions regarding staffing, scheduling, and equipment allocation to improve efficiency and performance.

Solution: A wireless magnetometer reliably detects vehicles by detecting changes in the magnetic field. Status information can be sent wireless using a wireless controller inside the facility. The controller counts each arrival and departure at a bay, logs the time at which the event occurred, and relays any change in status to one of several network-connected tower lights.

Benefits: Data can be accessed later and can be used to track and improve turnaround performance, identify inefficiencies and process issues, and allow supervisors to make smarter decisions about their staff and equipment.

Radar Sensor

리치 스태커, 지게차 및 채광 차량 등과 같은 보드 이동식 장비의 충돌 방지에 이상적인 고감도 레이더 기반 센서.

- 4세대 FMCW(true-presence) 레이더로 이동 및 정지 상태 물체 감지

- 감도가 더 높고 유효 거리가 더 긴 모델

- 감지 영역 조정 가능 - 설정값을 벗어난 물체 무시

- 간단한 DIP 스위치로 범위, 감도, 출력을 쉽게 설정, 구성

- 바람, 비, 눈, 안개, 습도, 대기 온도, 조명에 의한 센싱 기능 영향 없음

- 특별한 라이선스 없이 산업용, 과학용, 의료용(ISM) 통신 대역에서 작동 가능한 센서

- 튼튼한 IP67 하우징으로 가혹 환경 내구성 확보

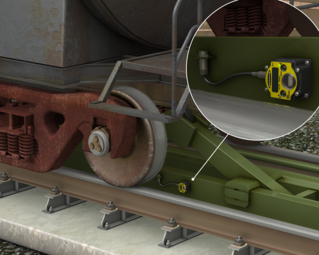

Wireless Magnetometer

M-GAGE 센서는 수동 감지 기술을 사용하여 자동차 등과 같이 철을 함유한 대형 물체를 감지합니다. M-GAGE는 유도 루프 시스템을 대체하고 외부 제어 박스가 필요 없습니다.

- 온도 변화 및 자기장 변동의 영향을 최소화하도록 설계되어 있습니다.

- 센서가 주위 배경을 학습해 비휘발성 메모리에 설정을 저장합니다.

- 하우징에 통합된 1차 리튬 배터리 1개가 FlexPower 기술을 구동합니다.

- 트랜시버가 완전히 확인된 데이터 전송을 비롯해 게이트웨이와 노드 간에 양방향 통신을 제공합니다.

- 밀폐된 완전 포트형 하우징에 완전한 무선 솔루션을 위한 전원, 센서 및 안테나가 포함되어 있습니다.

Wireless Ultrasonic Node

무선 초음파 센서 노드는 옥내 주차 응용 분야에 이상적입니다.

- 주차장 천장에 직접 장착해 아래 주차 공간에 차의 존재 여부를 식별할 수 있습니다.

- 최대 4m 거리에 떨어진 물체를 감지합니다.

- 통합형 D-셀 배터리는 와이어 및 회로를 배선할 필요를 없애 설치 비용을 줄입니다.

- 온보드 온도 측정을 통한 온도 보상 기능을 활용해 설계되었습니다.

- 트랜시버가 완전히 확인된 데이터 전송을 비롯해 게이트웨이와 노드 간에 양방향 통신을 제공합니다.

- 하우징에 완벽하고 강력한 무선 솔루션(IP67, NEMA 6)을 위한 배터리, 센서, 안테나가 포함되어 있습니다.