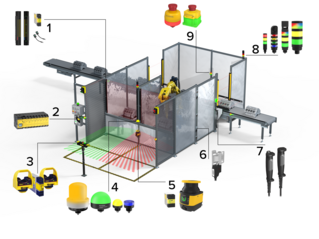

Safely Start and Stop Machines

Safety and Indication for Machine Start/Stop

Operators must be able to safely start machine processes as well as safely stop them in an emergency using a variety of safety-rated devices including emergency stop buttons, rope pulls, and two hand control devices.

Banner Engineering combines ergonomic safety-rated devices with LED indication for a more intuitive user experience and at-a-glance visual management of your safety systems. Keep reading to learn about the different types of safe operator interfaces.

Emergency stop buttons (or e-stops) and rope pulls ensure safe stops in emergencies. E-stops are mechanical buttons that must be pressed with force to actuate. Pressing an e-stop, or pulling the rope on a rope pull, will immediately stop hazardous motion of the machine.

Two hand controls are devices that initiate machine processes, for example when operating a mechanical power press. The operator must have one hand on each control before the machine will safely start, and the machine will continue operation only as long as both hand controls are actuated. This ensures that the operator's hands are away from the point of operation during the entire time the machine is moving.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application before implementing any machine safety measures.

Illuminated Base Quickly Identifies Pressed Button

With traditional e-stops, it can be time-consuming to determine exactly which button was pressed, and typically an emergency stop condition requires a reset of all e-stop buttons on a line. To solve this challenge, illuminated e-stops have an LED base that can be configured to change from yellow to flashing red when pushed. The colored lights n the e-stop base provide easy visual indication of armed button, pushed button, or system status.

This makes it easy to quickly see the status of all estops at a glance and instantly identify an actuated button. The faster the response to the stop condition, the more quickly the machine can be restarted, reducing unplanned downtime. lluminated e-stops can also reduce commissioning time and costs due to the ability to series connect the e-stops to a safety controller. This not only reduces cable costs and wiring time, but also reduces the number of inputs used at the safety controller.

Quickly Identify Pull Rope with LED Indicator

Rope pull switches run along the length of a conveyor so the operator can grab and pull it from anywhere to immediately stop the conveyor. When the rope is pulled, it can often be difficult to locate the safety device in need of reset. To help the operation to return to normal quickly, a LED domed indicator can be mounted to the housing of rope pull switches for fast identification of the unit that was activated.

Spans of rope range from 6 m to 100 m, providing the flexibility to safeguard long or short conveyors. Rope pull switches from Banner are also made with heavy-duty thermoplastic housing for use in demanding industrial settings.

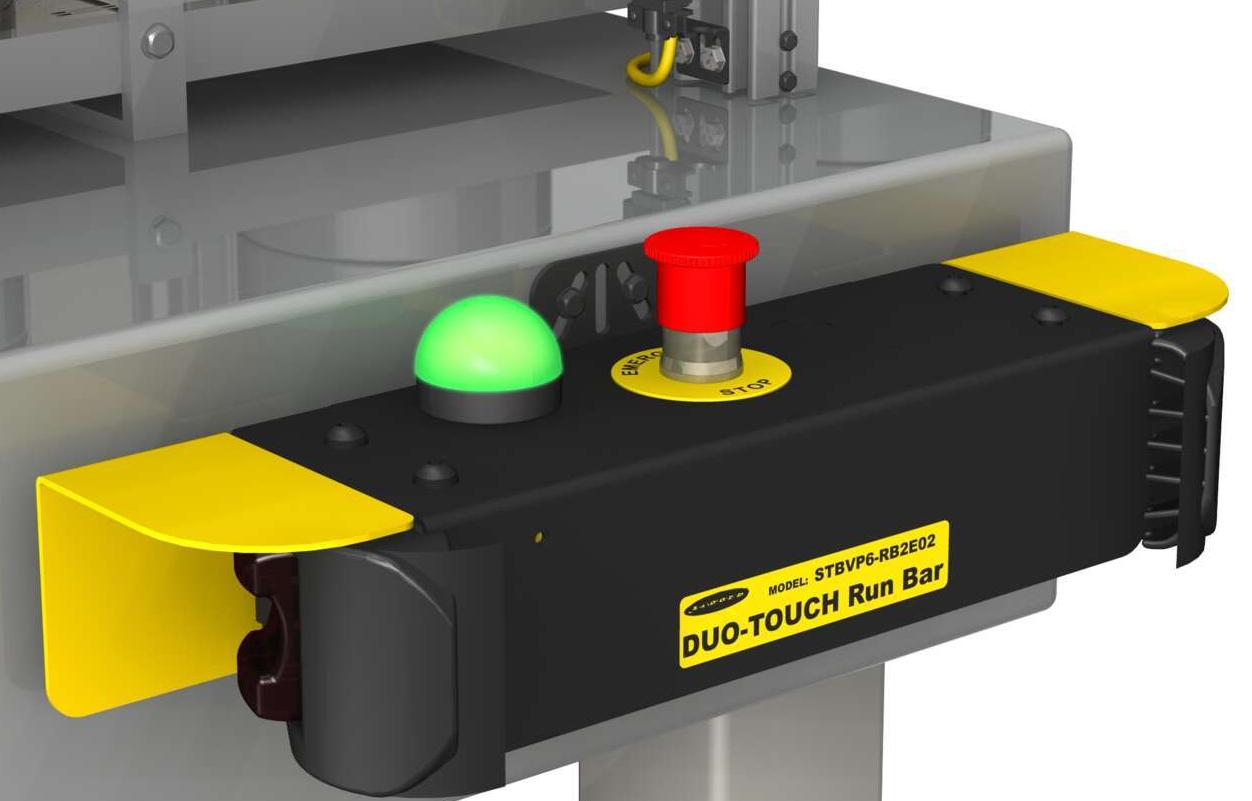

Start, Stop, and Indication Functions in One Ergonomic Solution

A run bar combines two hand control devices, e-stops, and indicators into a convenient ergonomic solution for operating machinery. The two-hand control system makes the operator a “hostage” while the hazard is present, preventing the operator from putting their hands in the way of the hazard.

Two hand control actuators must be located in a way that hazardous motion is completed or stopped before the operator can release one or both of the buttons and reach the hazard.

Ergonomic Design, Intuitive Visual Management

특허받은 30 mm 장착 베이스를 사용하여 조립, 개별 배선 또는 추가 인클로저 없이 쉽게 설치하고 연결할 수 있습니다.

- 바로 설치 가능한 완전 밀폐식 비상 정지 버튼으로 인건비 현저하게 감소

- 여러 개의 버튼을 직렬로 연결할 수 있으며, 로직이 내장되어 푸시 버튼의 명확한 표시 가능

- 래치 설계는 IEC 60947-5-1에 따라 ISO 13850 직접(포지티브) 개방 동작 표준 준수

- IP65 등급의 견고한 디자인

Emergency Stop for Conveyors & Large Machines

강삭과 함께 사용하는 경우 로프 당김 비상 정지 스위치는 컨베이어 및 대형 장비의 비상 정지 기능을 구동합니다.

- 사용 가능한 범위: 6~100m

- 트립 및 래치 모델로 제공

- 최소 스위치 수명: 1백만 번의 작업 횟수

- 혹독한 환경에서도 끄덕 없는 견고한 스위치 하우징

- 로프를 당기거나, 로프가 느슨해지거나 끊어지면 스위치가 작동

- 로프 당김 스위치에 대한 확실한 개방 요건을 충족시키는 설계

An Ergonomic Solution for Machine Start/Stop

DUO-TOUCH SG 양손 제어 모듈과 연동될 때 양손 제어 작동 및 보호를 위한 인체 공학적이며 강력한 솔루션.

- DUO-TOUCH SG 양손 제어 모듈 또는 이와 유사한 제어 시스템과 연동될 때 양손 제어 작동을 위한 편리하고 경제적인 수단

- 손, 손목 및 팔 스트레스 감소를 위한 인체 공학적 디자인

- 비상 정지 버튼을 사용할 수 있는 모델

- 밝은 LED 전력, 출력 및 오류 표시등

- ANSI B11.19 및 ISO 13851(EN574) 표준 충족