Factory Communication and Process Optimization

Communicate Better, Improve Worker Productivity

Industrial Internet of Things (IIoT) technologies are not just useful for optimizing machines. In fact, wireless technologies enable seamless interaction among human workers as well, and can have a significant impact on the efficiency of manual or semi-automated production and assembly lines.

Keep reading to learn how IIoT technologies enable better communication throughout the factory and streamline processes for machines and people alike.

Combining wireless communication with bright indication enables more seamless interaction between machines, workers, mobile equipment, and their managers throughout the factory.

Workers can quickly and easily interpret signals from LED indicators with clear, bright local displays, especially when each status is represented by a unique color or animation.

Furthermore, LED indicators with wireless communication make it easy to quickly send and receive these signals from anywhere in the factory--and respond in a timely manner.

Keep Stations Stocked for Continuous Workflow

Assembly workers need the correct supplies in order to build products and maintain a smooth workflow. Restocking assembly stations on-time, before components run out without overstocking and creating congestion at a station can be a challenge. Real-time communication between assemblers and the forklift operators who stock their stations enables a more efficient delivery of components as well as the timely removal of completed products.

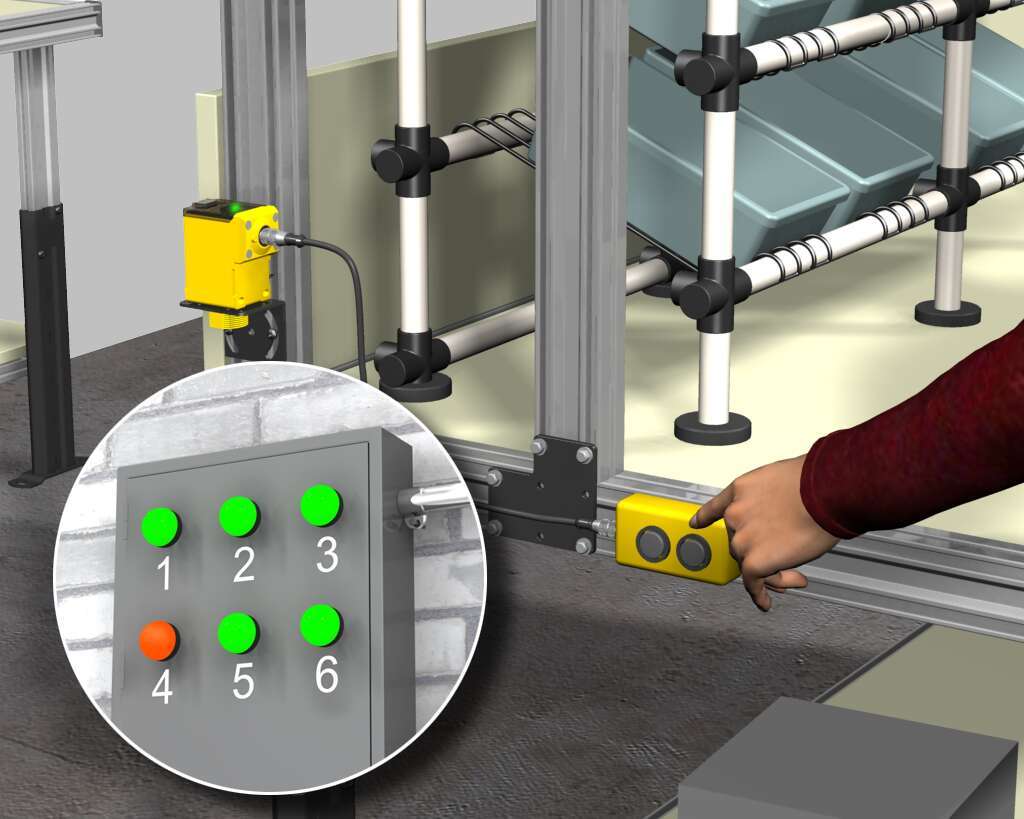

When an assembly station needs to be restocked, a worker can simply touch a button at their station. The button sends a signal to a pendant that the forklift operator carries. A red LED light on the pendant that corresponds with the assembly station will begin to flash, notifying the forklift operator where parts are needed. The driver can quickly acknowldege the request by pushing a button on the pendant, letting the operator know more material is on the way.

Use Data to Identify Process Improvements

A wireless call-for-parts, service, or pallet pickup system increases efficiency by allowing up to 18 work stations to call out to six forklifts or Hi-Los. A wireless solution enables quicker responses from forklift drivers and/or supervisors to indicate a request has been accepted. When creating a call system using wireless indicators, work stations can maintain a steady workflow and resolve critical issues quickly.

A wireless solution can also track total time to fulfill requests, number of requests, and time to acknowledge requests. This allows managers to analyze average delivery and acknowledgement times for each station and make process improvements as needed.

Reduce Time Spent Checking In Unnecessarily

Instead of requiring machine operators to walk over to the manager area for assistance with a technical issue, a wireless system utilizing connected pushbuttons or switches and tower lights can be used to alert managers when assistance is needed on the line.

For example, a notification system might be set up so that an operator pushes a button or flips a switch to alert the manager or technician that he or she is needed on the production line. Wireless pushbuttons equipped with LED status lights can also facilitate 2-way communication by configuring the LED to change color when the manager or technician indicates that he or she is on their way.

Using a wireless notification system reduces the need for technicians and managers to constantly check each production line and for workers to leave their workstations when they need assistance. By streamlining communications, managers, technicians, and line workers are able to use their time more productively.

Wireless Pushbuttons and Switches

Sure Cross® Q45 스위치 및 푸시 버튼은 다양한 공장 자동화, 원격 모니터링 및 IIoT 응용 분야에 사용하기 위해 원격 건식 접점, NAMUR 및 개별 비접촉 스위치 입력을 수용하기 위해 설계되었습니다.

- 원격 장치 모델은 절연된 건식 접점 입력 또는 NAMUR 유도형 근접 센서와 접속하도록 설계되었습니다.

- 버튼 및 표시등 모델은 푸시 버튼 입력과 다중 색상 LED 표시등을 독립적으로 제어합니다.

- 원격 이산 비접촉식 스위치 모델은 리드 스위치와 자석을 사용하여 도어, 레버 및 기타 액추에이터 등과 같은 기계 장치의 위치를 감지합니다.

Wireless Button and Light Pendant

Sure Cross® 무선 Q120 버튼 및 조명 펜던트는 작업자와 최대 6개의 원격 및/또는 모바일 장치 간에 양방향 통신을 가능하게 하는 자율 무선 노드입니다.

- 독립적으로 제어되는 푸시 버튼 입력 6개를 통해 작업자는 원격으로 상태 업데이트 및 확인을 전송하고, 프로세스를 시작하고, 장치를 구동 할 수 있습니다.

- 빨간색 및 녹색 LED 표시기 6개는 원격 또는 모바일 장치 및 장비의 상태를 현장에서 표시합니다 .

- DIP 스위치 구성 가능

Wireless LED Touch Button

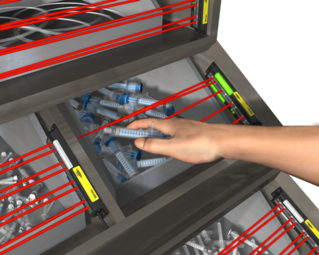

K70 70 mm 무선 터치 버튼은 작동하기 쉬운 대형 반도체 스위치 겸 고가시성 표시기입니다. 이 시리즈의 터치 버튼은 Pick-to-Light, 호출 버튼, 일반 산업 용도로 사용하기에 이상적입니다.

- 물 분무, 세제, 오일 및 기타 이물질로 인한 잘못된 트리거에 대한 뛰어난 내성

- 스위치 반복 조작과 관련된 손, 손목, 팔의 압박을 제거하도록 인체공학적으로 설계되어 작동하는 데 물리력이 필요 없음

- 맨손이나 장갑을 낀 손으로 작동할 수 있음

- 9가지 색상 옵션과 1, 2 및 3색 모델 사용 가능

- 12~30V DC 작동