High Speed Sensing Applications

Maintain High Throughput and Quality

Manufacturers must keep lines moving quickly in order to meet production goals and maximize efficiency. However, very high speed applications can be challenging for the sensors that verify part presence, inspect part quality, count parts, and more.

In material handling and logistics, maintaining efficiency without sacrificing quality and accuracy is also critical.

To ensure quality in high speed processes, facilities depend on reliable detection and measurement solutions that can keep pace.

High Speeds Plus Challenging Targets

- Many high speed applications also include extremely challenging targets, including clear, reflective, multicolored, and extremely objects.

- In some cases, the application may require extremely precise measurement of challenging targets at very high speeds.

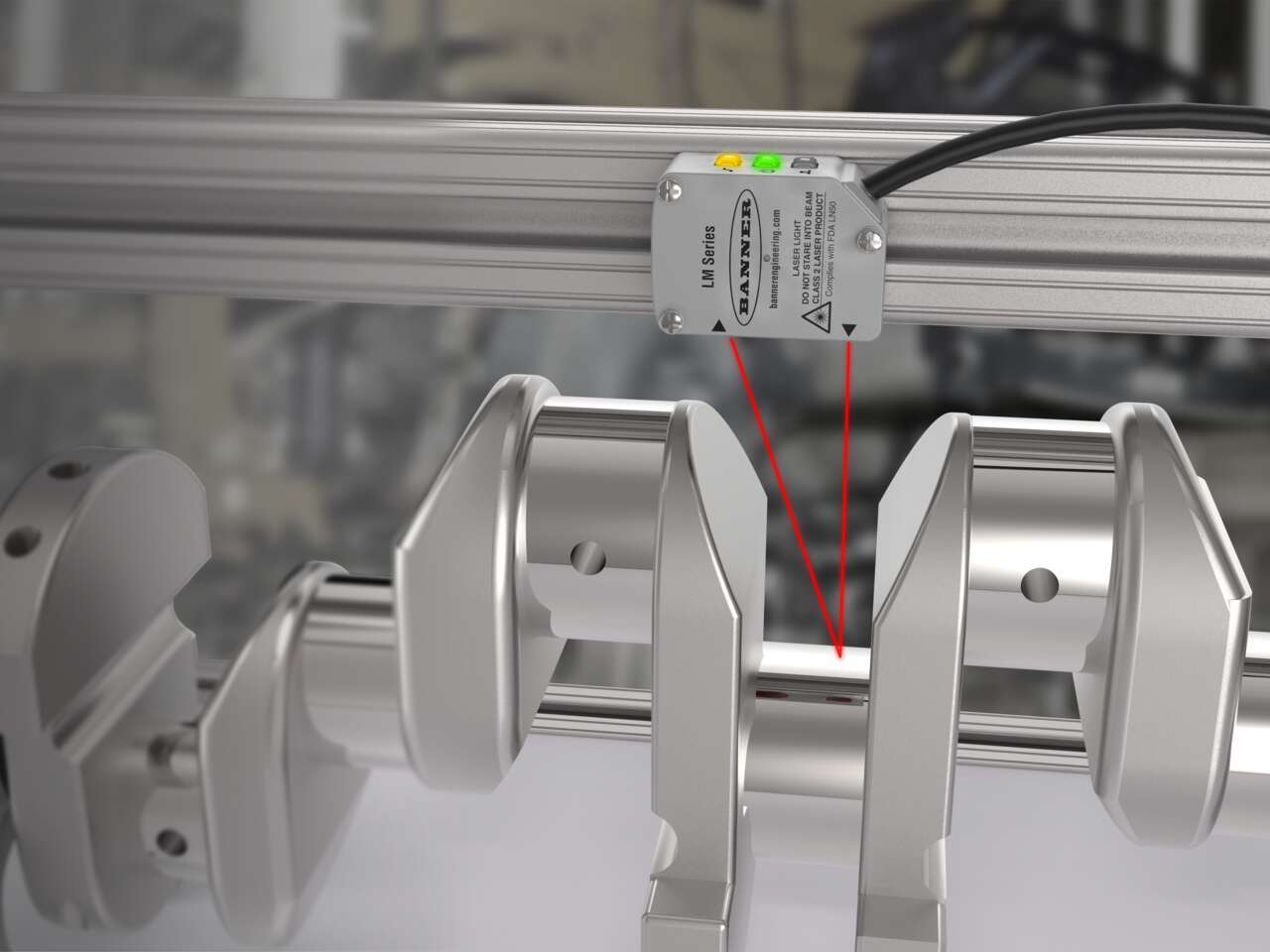

- For example, in automotive manufacturing, crankshaft runout measurements must be monitored continuously to ensure that they meet tolerance requirements. The reflective surface of the crankshaft and the high speed and precision of the application can be challenging for sensors to measure reliably. Learn how the LM Sensor solves this challenge.

- Banner offers a variety of sensing solutions for the most difficult high speed applications. See example solutions below or contact us to discuss your application.

Registration Mark Detection

Packaging Industry

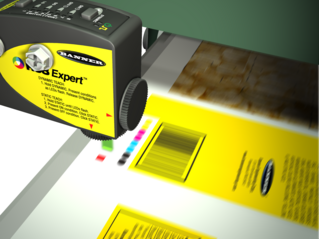

- Primary packaging has many high-speed processes, and it is important to verify correct packaging, which can be done by detecting registration marks.

- White registration marks on dark backgrounds, such as blue, can be challenging to detect at high speeds since many sensors are not able to maximize contrast for reliable detection of the mark and not the background.

- Banner Engineering's Q3X versatile, rugged laser contrast sensor is ideal for detecting registration marks. With a range up to 300 mm, the Q3X has a tight laser spot able to detect a small white registration mark reliably.

High Speed Tablet Counting

Pharmaceutical Industry

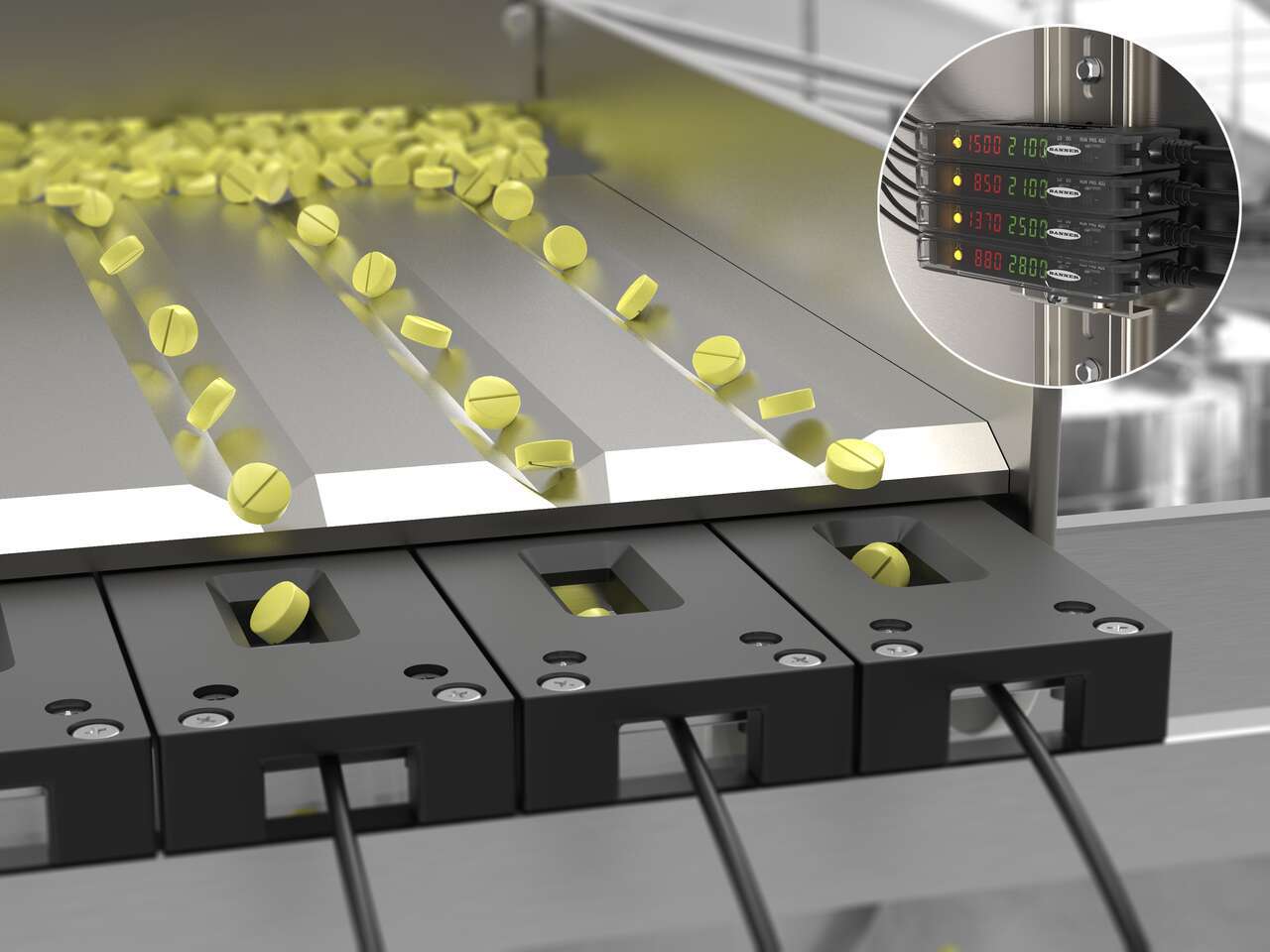

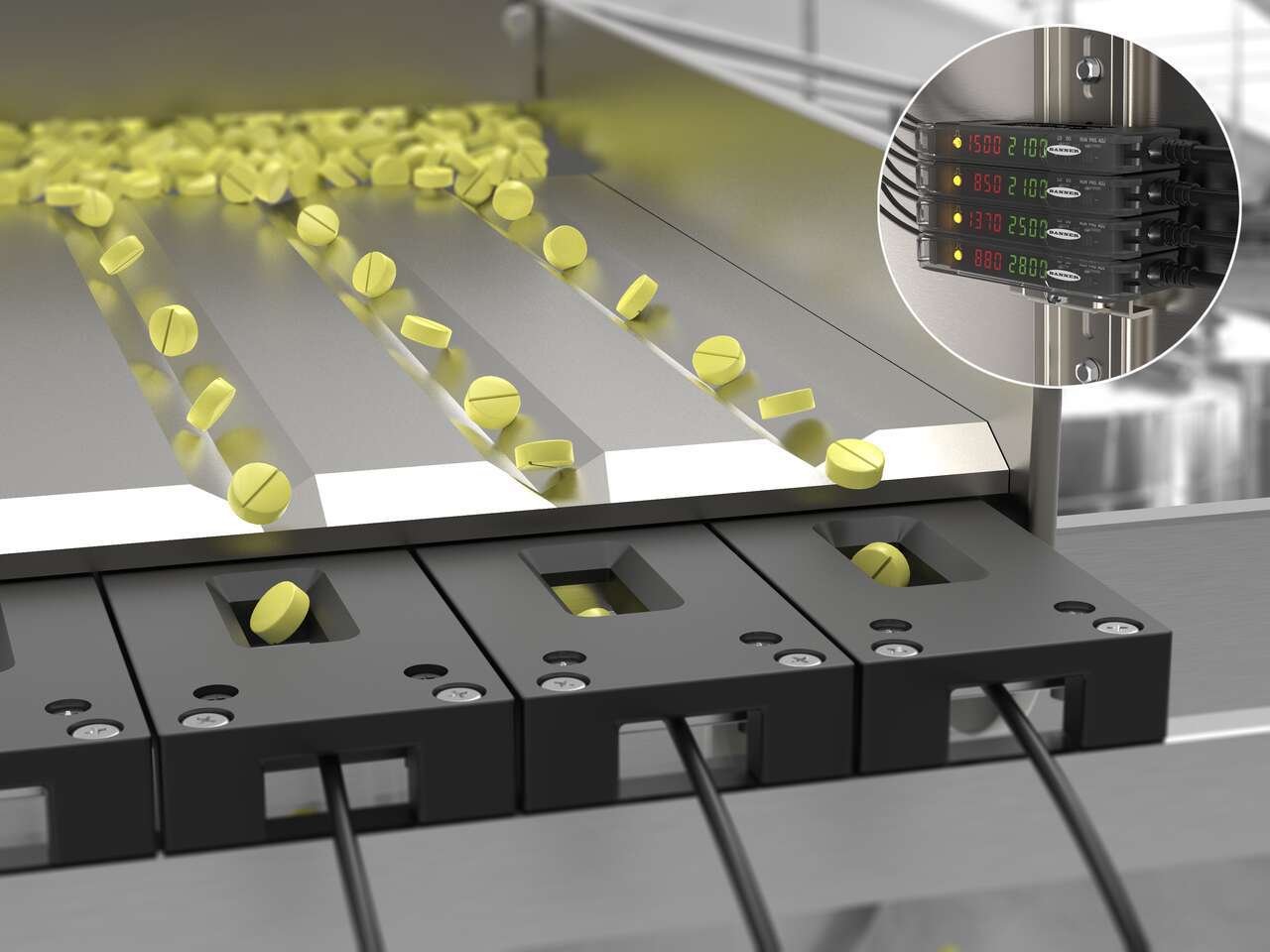

- In pharmaceutical packaging, products such as tablets, capsules and gel caps need to be accurately counted to achieve the proper number of tablets in each bottle.

- Pharmaceutical and medical industries use a dispensing mechanism to ensure the tablets separate from one another and don’t fall into the bottle side-by-side or simultaneously.

- All of this is done very quickly, creating the need for a high-speed, small-object counting sensor that can ensure tablets are accurately dispensed.

- The DF-G2 fiber optic amplifier is designed for high speed applications and can achieve 10 microsecond response time with 5 microsecond repeatability.

High Speed Box Profiling

Material Handling Industry

- Sorting parcels and packages prior to delivery is an essential step in shipping and handling.

- Order fulfillment applications rely on accurate automated sorting to keep costs down, maximize efficiency, and accommodate large volumes of packages during peak shipping seasons.

- To reduce the risk of error, an automated profiling solution is necessary to scan packages to ensure accurate—and fast—sortation.

- LE Series laser measurement sensors are an ideal solution to this applicaiton due their fast 5-10 millisecond response speed and ability to reliably detect any target, regardless of size, color or reflectivity.

DF-G2 Series

High Speed Fiber Optic Amplifier

세계에서 가장 빠른 응답 속도를 낼 수 있도록 설계된 DF-G2 광학 증폭기는 응답 시간은 10마이크로초로, 5마이크로초의 반복성을 구현할 수 있습니다.

- 원격 모니터링 및 구성을 가능하게 하는 IO-LINK 모델

- 동급 최고의 응답 속도: 10μs, 15μs, 50μs, 250μs, 500μs 및 1000μs

- 신호 레벨과 임계값을 표시해서 쉽게 판독 가능한 이중 디지털 디스플레이

- 단순한 사용자 인터페이스를 적용해서 디스플레이와 스위치/버튼 또는 원격 입력 기계 교육 와이어를 통해 센서 설정과 프로그래밍을 쉽게 수행

- 전문적인 TEACH 및 SET 방식을 통해 고속 또는 대비가 낮은 응용 분야를 포함한 모든 응용 분야에 대해 최적화된 이득과 임계값 보장

- 시동 시간을 단축하고 작동 중 신호 안정성을 유지하는 열적으로 안정적인 전자 장치

LE Series

Laser Measurement Sensor

LE 시리즈 선형 어레이 기술을 통해 감지 대상의 색상이나 광택에 관계없이 뛰어난 성능과 해상도를 제공합니다.

- 즉시 사용할 수 있음

- 직관적인 2줄, 8자 디스플레이로 조정이 쉬움

- 선형 어레이가 까다로운 대상에 대해 반복성과 정확성 제공

- 작은 스포트 크기 및 쉬운 정렬을 위한 가시 레이저

- IO-LINK 모델 사용 가능

H2