Stocking and Replenishment

Keep Shelves and Stations Stocked and Organized

Picking activities are only effective if the correct parts or inventory are put in the right place and ready to be picked. Because of this, an efficient stocking and replenishment solution is a necessity in many industries.

Warehouses and distribution facilities require an efficient method for putting inventory on the shelves so that orders will be easily accessible during fulfillment. In manufacturing facilities, assembly and kitting stations must be replenished with parts before they run out.

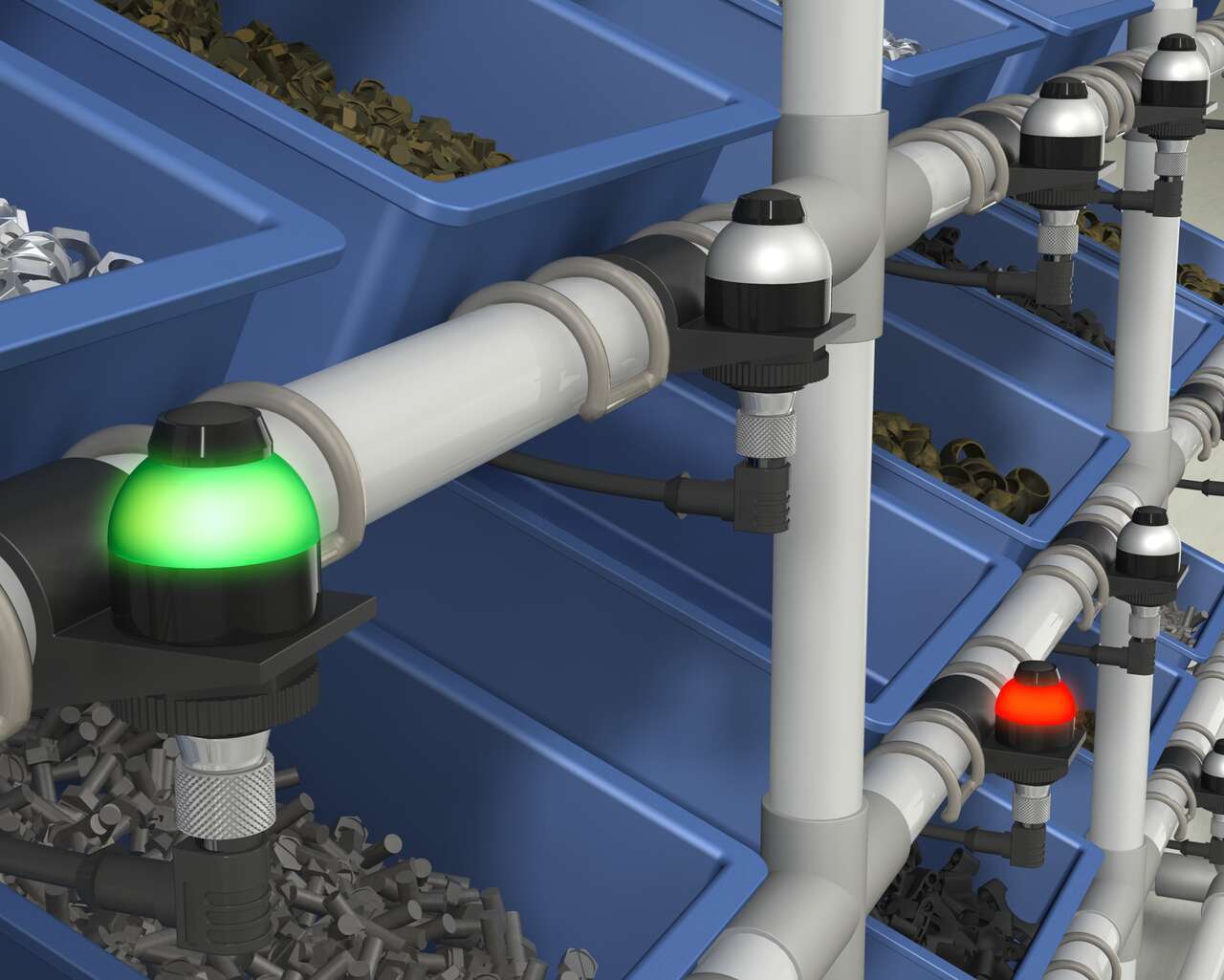

Put-to-light solutions improve the efficiency and accuracy of stocking and replenishment activities and can help prevent downtime by reducing delays due to misplaced or incorrect parts.

Stocking and replenishment are critical because misplaced items, incorrect parts, and delays in restocking shelves or workstations can significantly impact productivity downstream.

Proper stocking and replenishment is also essential for error-proofing and quality control. For example, if assembly stations are stocked with incorrect parts, the quality of the assembly may be compromised, and assemblers may not be able to meet production goals. In material handling, misplaced inventory can lead to order delays or mix-ups.

Light-guided putting solutions reduce the risk of errors and help ensure that work areas are properly stocked at all times.

Stocked Workstations Mean No Waiting for Items

- Put-to-light solutions speed up stocking and replenishment times by clearly and visually guiding workers to the correct location for each item.

- Faster replenishment means assemblers and production staff spend less time waiting for more parts and can maintain an appropriate pace to meet production goals.

- Efficient stocking also enables faster and more accurate order fulfillment at warehouses and distribution facilities.

Get the Right Items in the Right Location

- By facilitating proper stocking and replenishment, put-to-light solutions help ensure the quality of the final product.

- In manufacturing facilities, keeping assembly stations stocked with the correct parts reduces the risk of errors down the line.

- For example, a put-to-light solution uses light to guide a worker to place the proper size screws in the correct bins so the assembler will pick the right size screw to fasten other parts together securely.

Reduce Recalls & Ensure Customer Satisfaction

- Because put-to-light solutions improve efficiency and reduce errors, they ultimately help save costs and maximize profits.

- Fewer errors mean a lower risk of a product recall due to manufacturing defects.

- Speed and accuracy increase customer satisfaction and confidence, leading to repeat business and higher profits.

Versatile, Scalable Pick-to-Light Devices

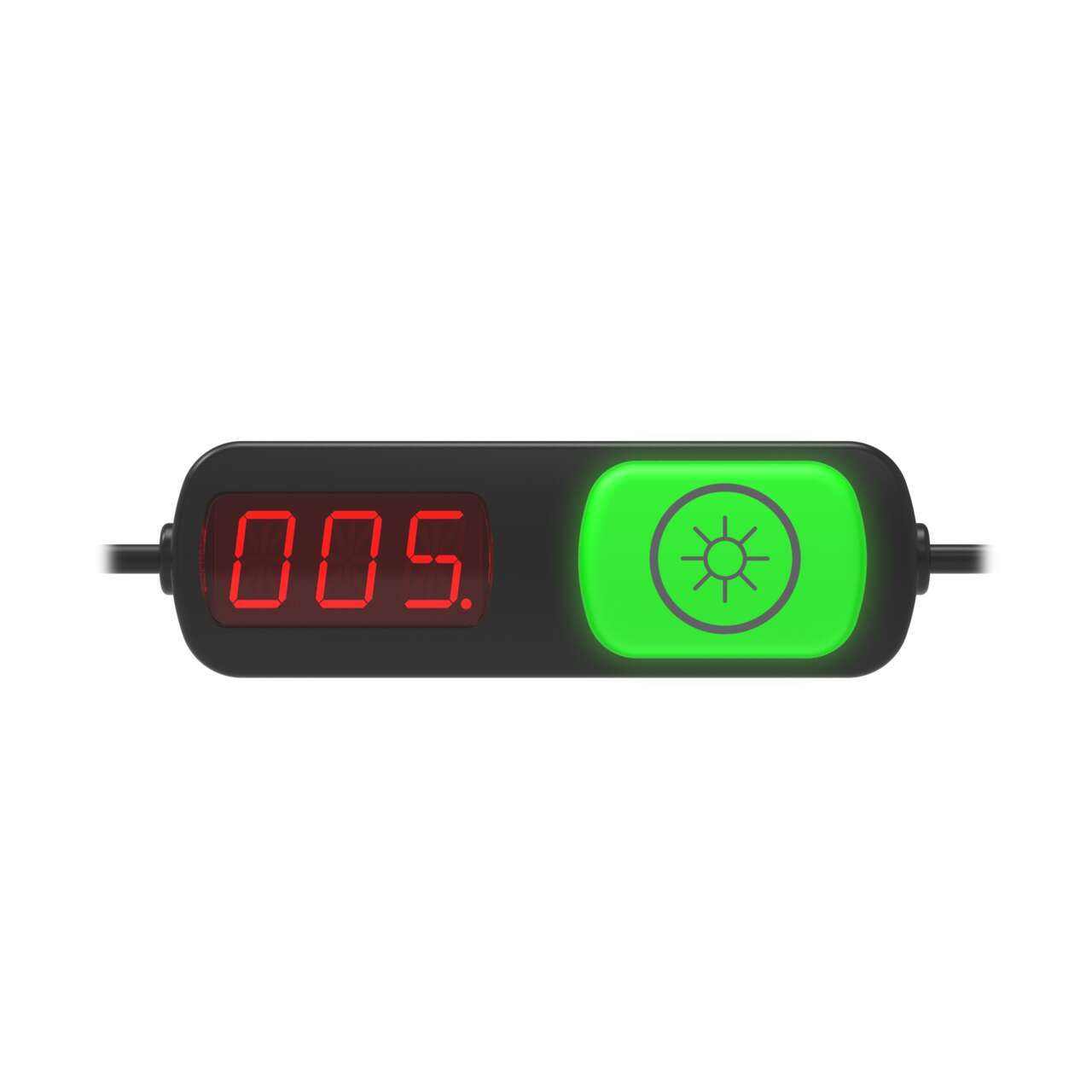

PTL110 Pick-to-Light 장치는 터치 버튼, 광학 센서 및 세 자리 디스플레이를 위한 옵션을 갖춘 다기능 표시등으로, 직렬로 연결되어 강력한 피킹 시스템을 구성합니다. 빠른 응답 시간과 유연한 설치 옵션을 갖춘 PTL110 시스템은 피킹, 키팅 및 관련 응용 분야에서 속도, 생산성 및 품질을 향상시킵니다.

- 광학 터치 센서 기능을 갖춘 모델로 제공됩니다.

- 선택적 3자리 영숫자 디스플레이를 사용하면 부품 개수를 표시하거나 다른 지침을 제공할 수 있습니다.

- M12 커넥터를 사용하면 추가 케이블이 없어도 여러 장치를 안전하고 빠르게 설치할 수 있습니다.

- 이 표시등은 14가지 색상 및 여러 애니메이션 기능을 제공해다양한 상태를 구분합니다.

- PICK-IQ™는 여러 장치를 폴링하는 데에서 발생하는 일반적인 지연을 단축하기 위해 공통 ID를 사용하도록 특별히 개발된 Modbus 호환 직렬 버스 프로토콜입니다.

- DXM700 무선 컨트롤러와 연결해 카트 및 이동식 피킹 스테이션에 배치할 수 있습니다.

Pick to Light Devices

Pick to Light Devices

S22 Touch 시리즈는 밝은 표시등과 간단한 터치로 작동하는 솔리드스테이트 전환 기능이 결합되었습니다. 린 제조 및 용기 선별 작업에 적합합니다.

- 터치식으로 구동되는 전환 기능을 갖춘 밝은 LED 표시등

- 색상 및 애니메이션을 사용자 지정하기 위해 Banner의 Pro Editor 소프트웨어 및 Pro 변환기 케이블을 사용하여 프로그래밍 가능

- 견고하고 비용 효과적이며 설치가 간편한 다색 표시등 및 터치 버튼

- 오랜 수명과 유지 보수 비용 절감을 위한 솔리드스테이트 전자 장치

- 세척 환경을 위한 IP69 구조

- 22mm 나사식 폴리카보네이트 베이스

- 손, 손목 및 팔의 스트레스를 제거하도록 인체 공학적으로 설계됨

- 맨손으로 또는 장갑을 낀 채 작동 가능