Multicolored Targets and Product Changeover

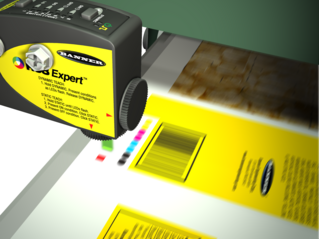

Multicolored targets are increasingly becoming the norm, especially in consumer packaged goods industries. The various types of packaging used include shiny, glossy, or other unpredictable surfaces.

For example, reflective, multicolored, and wrinkled material such as foil or film is frequently used in food and beverage packaging and can cause inconsistent sensor readings.

Multicolored targets are challenging for many sensors to consistently detect. This is because some colors, such as very dark colors, are more difficult for traditional photoelectric sensors to see because darker colors reflect back less light back to the sensor compared to lighter colors. Multicolored targets also have frequent color transitions and varying amounts of reflectivity that further impact sensing reliability.

Product changeover creates additional challenges because sensors must be able to reliably detect a variety of color combinations. To keep up with consumer demand, manufacturers require flexible sensing solutions that can detect all colors and that can be quickly updated with each new "recipe" during product changeover to keep production lines moving.

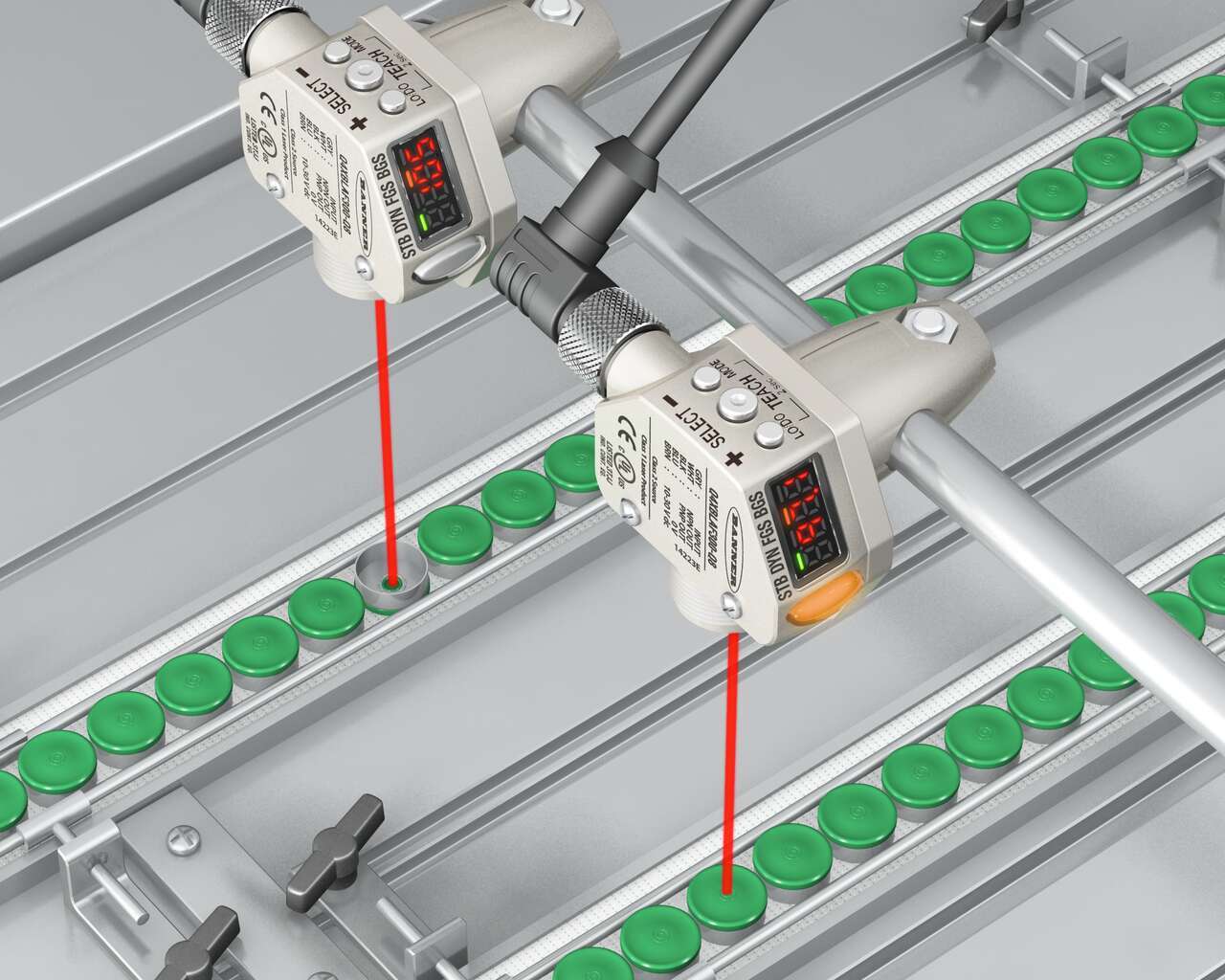

Laser distance sensors are an excellent choice for detecting multicolored packaging because cause they determine target presence or absence using distance. Laser distance sensors are unaffected by color transitions, and they can reliably detect all different varieties of packaging, regardless of color or reflectivity.

In addition, many laser distance sensors from Banner Engineering feature exceptionally high excess gain to reliably detect very dark colors, as well as automatic gain adjustment to dynamically increase or decrease sensing power depending on target reflectivity.

With IO-Link, users can easily read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources.

In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

Manufacturers use many terms to describe sensor performance, but not all manufacturers use the same specifications, which can make it challenging to compare different models of sensors. Read the article to learn tips for choosing the right sensor for any application.

Laser Distance Sensor with IO-Link, 25-610 mm

Versatile, rugged laser distance sensors offering superior performance and capable of detecting sub-millimeter changes in distance.

- Discrete, analog (0 to 10 V or 4 to 20 mA), clear object, and IO-Link models available

- Reliable sensing range from as close as 25 mm and as far as 610 mm

- Detects across a variety of target colors, materials and surfaces based on distance

- Dual teach mode (intensity + distance) is ideal for error-proofing applications and enables clear object detection with no retro-reflector required

- Robust housing rated to IP69K with FDA-grade stainless steel

Laser Distance Sensor with IO-Link, 9.5 cm to 2 m

Q5X 배경 억제 레이저는 산업 표준 직사각형 하우징으로 둘러싸인 경제적인 장치에 장착된 여러 가지 문제를 해결하는 강력한 센서입니다.

- 범위: 9.5 cm(4 인치)~2 m(6피트 6인치)

- 과잉이득이 예외적으로 높은 경우 이 센서는 가장 어두운 물체(반사율이 6% 미만인 검은색 물체)를 확실하게 감지할 수 있습니다.

- 검은색 배경을 뒤로 한 검은색 표적, 반짝이는 금속 배경을 뒤로 한 검은색 표적, 투명한 반사 물체, 다양한 색상의 포장 및 모든 색상의 표적을 감지할 수 있습니다.

- 이중 티칭 모드에서는 거리와 광도를 둘 다 측정해 가장 까다로운 응용 분야의 문제를 해결합니다.