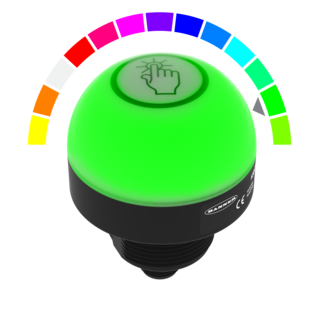

50 MM MULTICOLOR PROGRAMMABLE TOUCH BUTTON

K50 Pro Select Touch Series

The K50 Pro Select Touch is the go-to solution for numerous pick-to-light and call button applications across a wide range of industries and environments, quickly and easily configured to deliver clear process guidance, status indication, and user feedback.

- Cost-efficient design withstands harsh environments while reducing weight for easy system integration

- Delivers long-lasting performance in industrial environments with its rugged, sealed IP66-, IP67-, and IP69K-rated laser welded assembly

- Consolidate inventory and simplify ordering processes by purchasing and configuring one part that does the job of multiple devices

- Operates efficiently with advanced touch technology that reliably detects both bare and gloved hands

- Requires no physical pressure to operate, easing stress on hands and wrists

- Easily communicate via three default colors (red, green, yellow), with 14 colors and eight animations available via Pro Editor software

- Accommodate different touch sensitivity needs via Pro Editor configuration

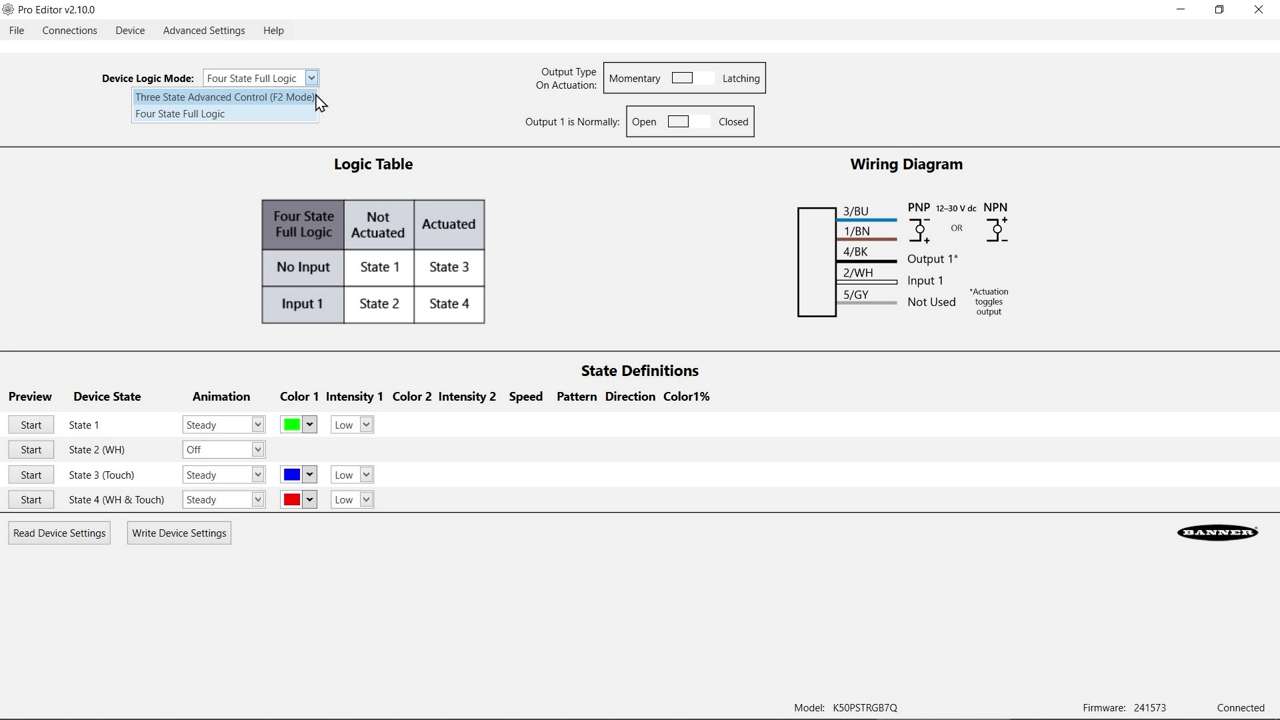

- Use in a variety of applications with either of two device logic modes

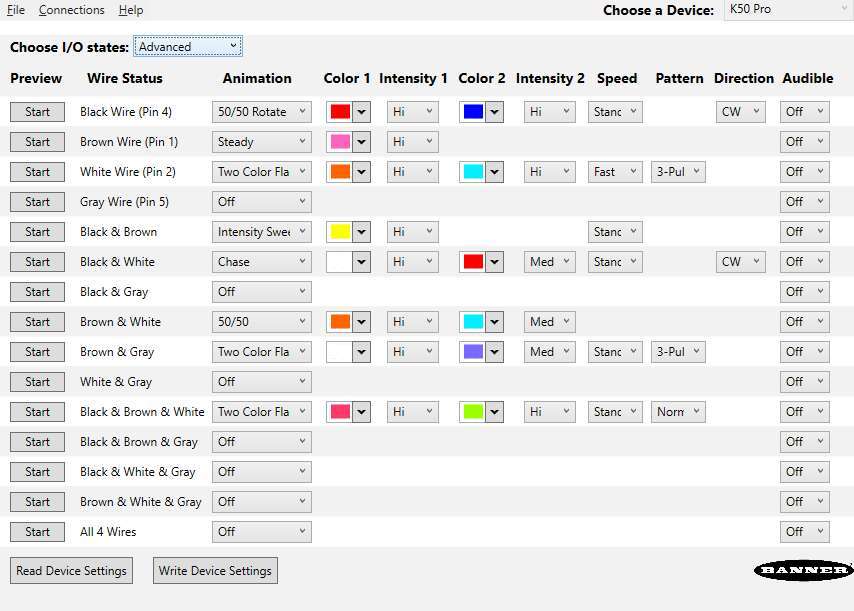

Pro Editor Software

With the Pro Editor software and Pro Converter Cable, you can easily customize indicators with a wide variety of color and animation options.

The software allows users to program their own devices in the field without requiring IO-Link.

소프트웨어

날짜

유형

크기

기술 문헌

날짜

유형

크기

날짜

유형

크기

날짜

유형

크기

날짜

유형

크기