DXM1200 IIoT Gateway Series

Banner’s DXM1200 IIoT Gateway wireless controllers collect and process condition monitoring data from nearly anywhere, then sends anywhere in the world.

A car wash depends on multiple systems working in tandem. Failure in any piece of equipment could cause an unexpected shutdown, resulting in lost revenue and unplanned maintenance.

But Banner Engineering can help you detect equipment breakdowns before they happen.

Maximize vehicle throughput and reduce unexpected downtime with Banner Engineering’s Predictive Maintenance Solutions for Car Washes.

To monitor equipment in the back room, use Banner’s Q45 All-In-One Series sensors, starting with an ultrasonic model that accurately measures the water level in the storage tanks. The vibration and temperature of the delivery pump’s motor gets monitored with another peel-and-stick Q45, and an additional Q45 monitors the water pressure on the main water line.

Further down the line, monitor the vibration and temp of all the different distribution pump’s motors, such as at the detergent pump station, sealer stations, and the high-pressure water pump stations.

Additionally, monitor the reclaim storage tanks for low water levels, which may indicate the RO’s filter needs cleaning. The reclaim delivery pump’s motor is also outfitted with a temp and vibration sensor to alert users to mechanical maintenance needs.

But monitoring solutions don’t have to stop at the water system; nearly any equipment can be monitored, such as the pneumatic air system. Temperature and vibration sensors monitor the air compressor motors alongside a current sensor for consistent power usage, as well as a pressure sensor on the primary air line.

Outside, monitor the central vacuum’s motor with a temp and vibration sensor. The filter’s efficiency can be calculated by comparing the air pressure both upstream and downstream of the separator, indicating when the filter needs cleaning.

All the data from each of these sensors is transmitted wirelessly to a DXM controller mounted in a safe and convenient location. Sensor calculations are performed inside the controller, and data can be transmitted to wherever you need it via Ethernet cable or a cellular connection. Additionally, alerts can be sent to workers via email or text message, so mechanical problems can be addressed quickly.

But, passive monitoring doesn’t have to stop there.

Back in the tunnel, use a temperature and vibration sensor to track the machine health and performance of the conveyor’s motor and gear box. Additionally, consider using a Q45 to track vibration on the air blowers.

Next, add a T30RW radar sensor to the tunnel entrance and exit to reliably detect when vehicles arrive and leave.

Further inside the tunnel, accurately detect vehicles at specific locations, such as an applicator arch, with the QS30 Photoelectric Sensor.

And speaking of applicator arches, Banner's extensive line of customizable RGB lights, many of which are programmable and animated, will add an exciting splash of color and movement while also indicating different wash levels, customer-selected sealers, progress indication, and more.

The only limit to indicator integration is your imagination.

To learn more, visit BannerEngineering.com/carwash

Banner’s DXM1200 IIoT Gateway wireless controllers collect and process condition monitoring data from nearly anywhere, then sends anywhere in the world.

50 mm 돔 또는 평면 윈도우가 있는 프로그래머블 다목적 표시기는 더 선명하고 밝은 상태 표시를 제공하며, Pro Editor 소프트웨어 호환성 또는 IO-Link 통신 중 하나를 사용하여 추가적인 다기능성과 사용자 지정 기능을 구현할 수 있습니다.

K70 표시등은 하나의 조명에 최대 5가지 색상을 지원하는 대형 70mm 표시등입니다. 이 표시등은 다양한 응용 분야에 사용할 수 있는 색상이 밝고 견고한 표시등입니다.

Q45 시리즈 올인원 장치는 무선 노드, 센서, 배터리 전원 공급 장치가 하나로 결합되어 원격 환경과 접근하기 어려운 위치에 배치하기 쉬운 자산 및 장비 모니터링 장치입니다.

QM30VT 시리즈 진동 및 온도 센서는 장비 상태와 성능의 매우 미세한 변화도 감지할 수 있는 탁월한 수준의 정밀도를 제공하므로 잠재적인 문제를 조기에 확인할 수 있습니다.

최대 200m 범위의 e/m 릴레이 출력 모델에서 고출력 감지 가능

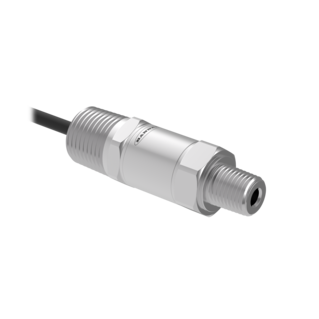

The Performance Series all-in-one pressure sensor and wireless node makes it easy to monitor pressure levels on systems and equipment in remote and hard-to-access locations without wired infrastructure to connect devices.

The T30R sensor is a longer-range alternative to ultrasonic sensors, and provides more reliable detection and position feedback in extreme outdoor conditions and other challenging environments. It features a shorter dead zone, better accuracy, and the ability to see a wider range of targets than traditional 24GHz radar sensors.

크고 밝은 타워 라이트가 사전 조립 형태 또는 맞춤형 표시에 적합한 모듈형 세그먼트로 제공됩니다. 잘못된 표시를 방지하도록 라이트가 꺼져 있을 때 회색입니다.

Banner is expanding its offering of the WLS27 Series Strip Light to include programmable models with RGBW LEDs for use in indication, illumination and inspection applications. These new models will be programmable with Banner’s Pro Editor software or IO-Link communication.

28mm 프로파일 컴팩트 LED 조명을 다양한 산업 분야에 사용 가능. 최대의 유연성을 위해 동작 센서, 렌즈 및 창을 사용할 수 있음.

Sure Cross® 온도 및 습도 센서는 다양한 환경에서 작동하는 온도 및 습도 측정 솔루션을 제공합니다. 이 센서 제품군을 Sure Cross 무선 통신 장치와 함께 사용하면 모니터링 지점까지 비용을 들여 배선을 설치하지 않고도 환경 상태를 손쉽게 모니터링할 수 있습니다.

Application solutions, new product updates, answers to frequently asked questions, and more delivered 1-2 times a month.