자동차: 프레스 공장 및 스탬핑 솔루션

-

투명 라벨의 산업용 바코드 검증

투명 라벨의 산업용 바코드 검증

자외선(UV) 링 라이트가 포함된 iVu BCR 모델은 저대비 상황에서 바코드를 감지하는 데 이상적인 솔루션입니다. iVu는 UV 조명과 함께 투명 라벨에 대한 대비를 개선하여 바코드를 손쉽게 감지할 수 있는 올인원 솔루션을 구성합니다.

-

QR 코드 판독용 비전 센서

QR 코드 판독용 비전 센서

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

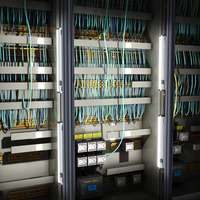

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

An equipment manufacturer builds test and measurement machinery for the auto industry. Operators access machine systems through the control cabinet. Intense illumination of the cabinet facilitates machine maintenance and management. Multiple AC powered fluorescent light fixtures had been used for this task.

-

Superior Light Distribution with LEDs [Success Story]

Superior Light Distribution with LEDs [Success Story]

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

각인된 금속 부품의 다중점 검사

각인된 금속 부품의 다중점 검사

작은 금속 부품에 구멍이 예상한 개수대로 있는지 확인하기 위해 iVuPlus TG 이미지 센서는 여러 관심 영역(ROI)에 맞춰 구성해 구멍이 있고 올바른 위치에 뚫려 있는지 확인할 수 있습니다. 면적 검사에 맞춰 설정하면 iVu는 각인된 부품 위의 다중점을 스캔해 관심 형상의 유무를 확인합니다.

-

Detecting Parts Ejected from Die [Success Story]

Detecting Parts Ejected from Die [Success Story]

In the manufacturer's facility, operators manually insert and remove metal parts from the die press. When complete, the parts are sent into a bin via a metal chute. In order to prevent die crash (having double parts in the press at once) the customer needed a sensor that could detect various parts on the chute and send a signal to the control system, indicating that the press is free and allowing the operator to perform another stroke. The solution needed to be installed without cutting slots in the chute sides or mounting sensors at the end of the chute, which could create catch points for traveling parts.

-

Wafer Cassette Detection Under Water

Wafer Cassette Detection Under Water

Silicon wafers are transported from one process to another in cassette on a conveyor that is totally submerged in de-ionized water. A D10 sensor has teflon-encapsulated opposed-mode fibers that are located on either side of the conveyor. When the cassette is present, the opposed beam is broken.

![Superior Light Distribution with LEDs [Success Story]](/content/dam/banner-engineering/photography/product-photography/wlb32/hofmann_enclosure.png/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Detecting Parts Ejected from Die [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/PVD-Part-Out.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)